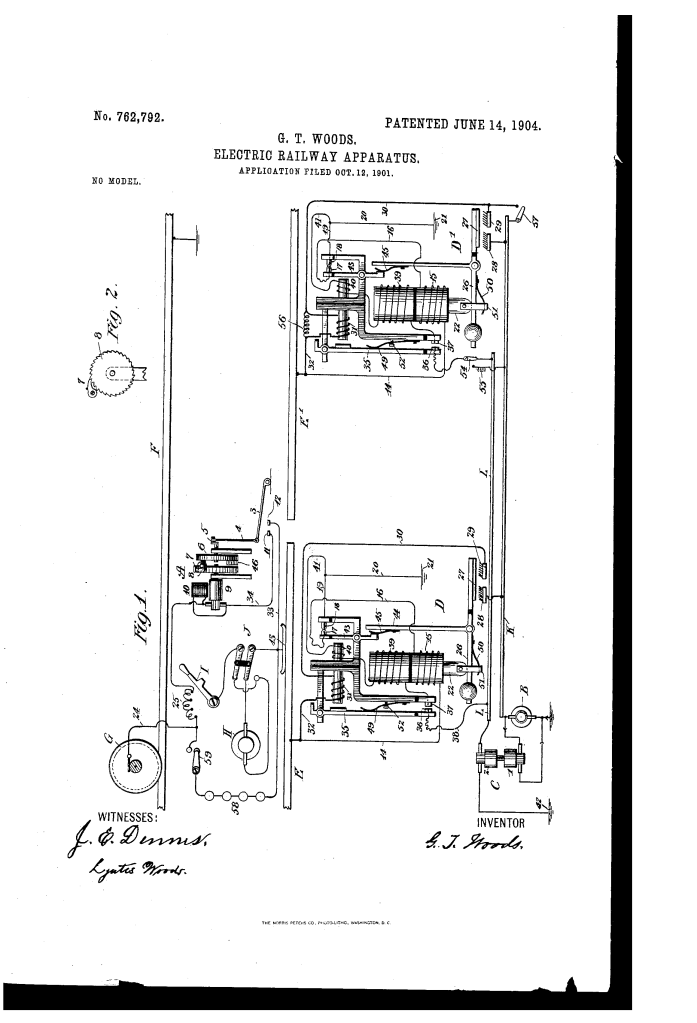

Electric-Railway Apparatus (Granville T. Woods, No. 762,792)

The patent by Granville T. Woods of New York, N.Y., describes an Electric-Railway Apparatus (Patent No. 762,792, 1904). The invention is an improvement on the surface-contact or sectional-conductor type of electric railways. The primary object is to produce an efficient, safe, and reliable system where a series of normally dead sectional conductors are automatically connected to a feeder, specifically addressing the problem of voltage drops and unreliable switches.

Inventor Background: Granville T. Woods

Granville T. Woods (1856–1910), the “Black Edison,” was an exceptionally important African-American inventor specializing in electrical and railway systems.1 This patent is a crucial late-career refinement of his work on surface-contact railways, focusing on complex circuit logic and using auxiliary low-voltage power to ensure the critical track switches operate reliably, even when the main line suffers severe power loss.

Invention and Mechanism (Simplified)

The system uses a low-voltage auxiliary power source to reliably operate the track switches, isolated from the unstable high-voltage main line.

1. Dual Power Sources

- Main Feeder (K): Supplies the high-voltage current (power) for the car motor (H).

- Auxiliary Feeder (L): Supplies low-voltage current for maintaining the track switches.

- Motor-Generator (C): A machine on the car (Motor 1 and Generator 2) transforms high voltage from the main line into the stable low voltage needed for the auxiliary feeder (L).2

- Car-Based Generator (9, 10): A small generator operated by a foot-lever (3) and a clutch (A) is used to provide the initial burst of current (pick-up) to close the track switches.

2. The Four-Coil Track Switch (Key Innovation)

Each track-side electromagnetic switch (D) has four coils and three internal switches, creating a highly reliable sequence:

- Actuating/Pick-Up Coil (15): Receives the initial burst of current from the car-based generator (9, 10) to quickly close the switch.

- Hold-Up Coil (39): Connected to the stable, low-voltage auxiliary feeder (L).

- Function: This coil’s job is to maintain the switch in the closed position. Since it receives low, stable voltage, it is unaffected by the “fall in potential” that often plagues high-voltage coils when the main line voltage drops (e.g., when many cars start simultaneously).

- Series Coil (31): Wired in series with the car motor (H).

- Function: Operates a switch (35) that closes the maintaining circuit connection to the auxiliary feeder (L), ensuring the hold-up coil (39) gets power only when the car is present.

- Circuit-Breaking Coil (40): Breaks the circuit to the initial pick-up coil (15) once the switch is closed.

3. Operation Sequence (Reliable Activation)

- Initial Pick-Up: Motorman presses the foot lever (3), activating the car’s small generator (9, 10). Current flows through the pick-up coil (15) of the forward track switch (D).

- Main Switch Closes: The initial coil (15) closes the main switch contacts (28, 29), connecting the track section (E) to the main high-voltage feeder (K).

- Hold-Up Activation: The main power flowing through the car motor (H) energizes the Series Coil (31). This closes a contact (35), activating the Hold-Up Coil (39) with the stable, low voltage from Auxiliary Feeder (L).

- Sustained Connection: The switch remains firmly closed by the stable low-voltage power until the car leaves the section.

Concepts Influenced by This Invention

Woods’s apparatus established foundational principles for redundant, low-voltage control systems in high-voltage environments, crucial for modern infrastructure reliability.

- Low-Voltage Maintenance Circuits (Decoupling): The most significant influence is the engineering strategy of decoupling the critical holding function (Hold-Up Coil 39) from the unstable main power circuit (K) by supplying it with a stable, low-voltage auxiliary feeder (L). This technique is fundamental to modern industrial safety systems, where control logic and relays are powered by separate, reliable low-voltage circuits.

- Multi-Coil Logic for Sequential Control: The use of four sequential coils (pick-up, hold-up, series, circuit-breaking) within a single switch influenced the design of sophisticated control relays and industrial automation devices that require a phased sequence of actions (close circuit, sustain, then cut initiating power).

- On-Board Power Conditioning (Motor-Generator C): The use of a motor-generator on the car to create a stable low-voltage source from an unstable high-voltage source influenced the design of power conversion and conditioning systems in all modern electric vehicles and railcars.

- Controllable Initiation: The use of a foot-lever and clutch mechanism to generate the initial pick-up current gave the operator precise, safe control over the start-up sequence, influencing the design of controls that require deliberate manual action for system activation.