Dust-Proof Bag for Street-Sweepers (Charles B. Brooks, No. 560,154)

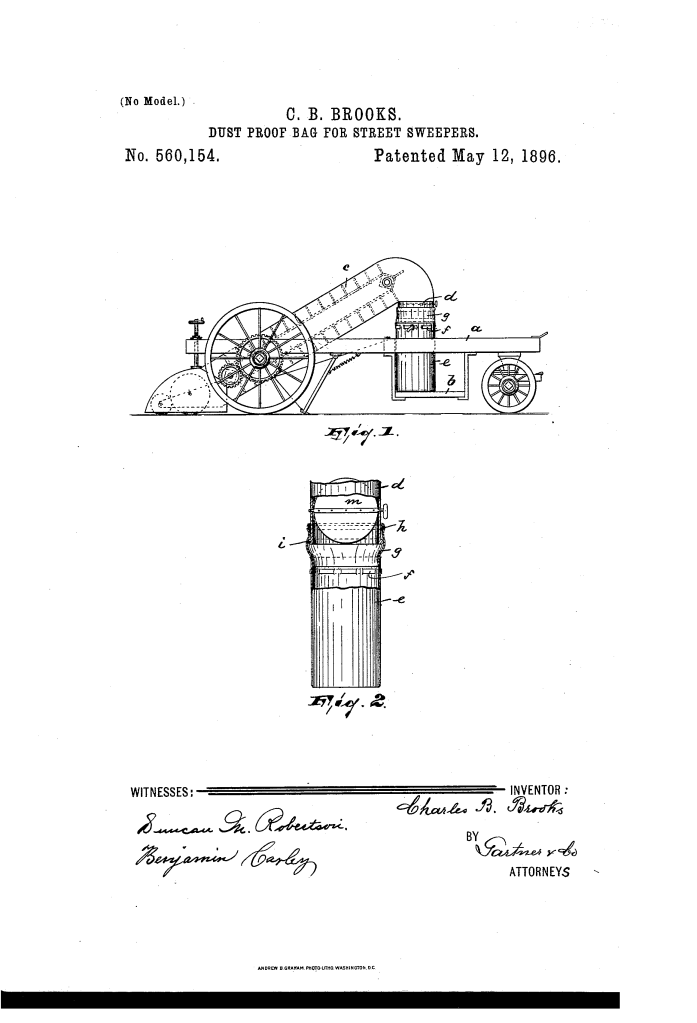

The patent by Charles B. Brooks of Newark, New Jersey, describes a Dust-Proof Bag for Street-Sweepers (Patent No. 560,154, 1896).1 This invention is an improvement designed to contain dust and dirt during the street sweeping process, particularly when the filled collection bags are being removed and replaced.

Invention and Mechanism

The invention focuses on the design of the bag and its connection point to the sweeper’s debris hopper.

- Bag Structure:

- Bag (): The main refuse receptacle.

- Tightening Strap (): A string or strap (preferably interlaced) located at or near the upper end of the bag.

- Function: This strap allows the bag to be closed tightly once it is filled, preventing dust from escaping.

- Dust-Proof Connection (Key Innovation):

- Extension-Sleeve (): An extension sleeve, made of canvas or other suitable material, is secured to the mouth of the bag ().

- Elastic Band (): An annular elastic band is arranged at or near the free end of the extension-sleeve (

).

- Function: The elastic band (

) is designed to engage and bind tightly against the circumference of the hopper () of the street-sweeper. This creates a dust-proof seal between the bag and the machine.

- Operation Principle (Dust Control):

- When the bag is filled, the damper (

) on the hopper is closed to temporarily stop the flow of debris.

- The bag is then tightened using the strap (

).

- Finally, the entire extension-sleeve (

) with its elastic band (

) is withdrawn from the hopper.

- Result: This multi-step sealing process ensures that “it is impossible for any dust or dirt to fly around while the bag is being closed.”

- When the bag is filled, the damper (

Historical Significance and the Inventor

Charles B. Brooks’s 1896 patent is a focused, necessary refinement of his earlier street-sweeper designs, underscoring the severity of the dust pollution problem in urban sanitation.

- Sanitation Engineering: While Brooks’s earlier patents focused on the mechanical sweeping action, this invention zeroes in on the logistical weak point—the point of transfer and collection. Dust created during the transfer of debris from the machine to the street or a wagon was a major public nuisance and health hazard.

- The “Dust-Proof” Goal: The patent’s explicit purpose addresses the critical challenge for all early mechanical sweepers: containment. The elastic-band seal and the pre-closure strap are practical, low-tech mechanical solutions to a major environmental problem of the day.

- The Inventor (Charles B. Brooks): Brooks, residing in Newark, New Jersey, was a specialist in municipal equipment.2 The assignment of two-thirds interest to his partners suggests the invention was part of a commercial product line aimed at municipal contracts.

Concepts Influenced by This Invention

Brooks’s dust-proof bag design influenced subsequent industrial and commercial systems requiring sealed interfaces for particulate transfer.

- Elastic/Drawstring Sealing for Collection: The concept of using a flexible sleeve with an annular elastic band to create a temporary, tight seal around a hopper or discharge port is the core mechanism used in modern:

- Industrial Dust Collectors: Collection bags on industrial vacuums, wood-shop dust extractors, and air filtration systems.

- Commercial Vacuum Cleaner Bags: Many reusable or disposable vacuum bags use a flexible, sealing collar to ensure an airtight connection to the machine’s inlet.

- Two-Stage Containment: The design utilizes two stages of containment—the internal hopper damper (

) and the external bag tightening strap (

)—before the seal is broken. This principle is standard in handling hazardous or volatile powders in pharmaceutical and chemical manufacturing, often achieved with sophisticated airlock systems.

- Flexible Transfer Interfaces: The invention reinforced the engineering principle that interfaces between rigid equipment (hopper) and flexible containers (bag) must be designed for airtight, quick-release engagement to minimize environmental contamination.