Dust-Pan (Lloyd P. Ray, No. 587,607)

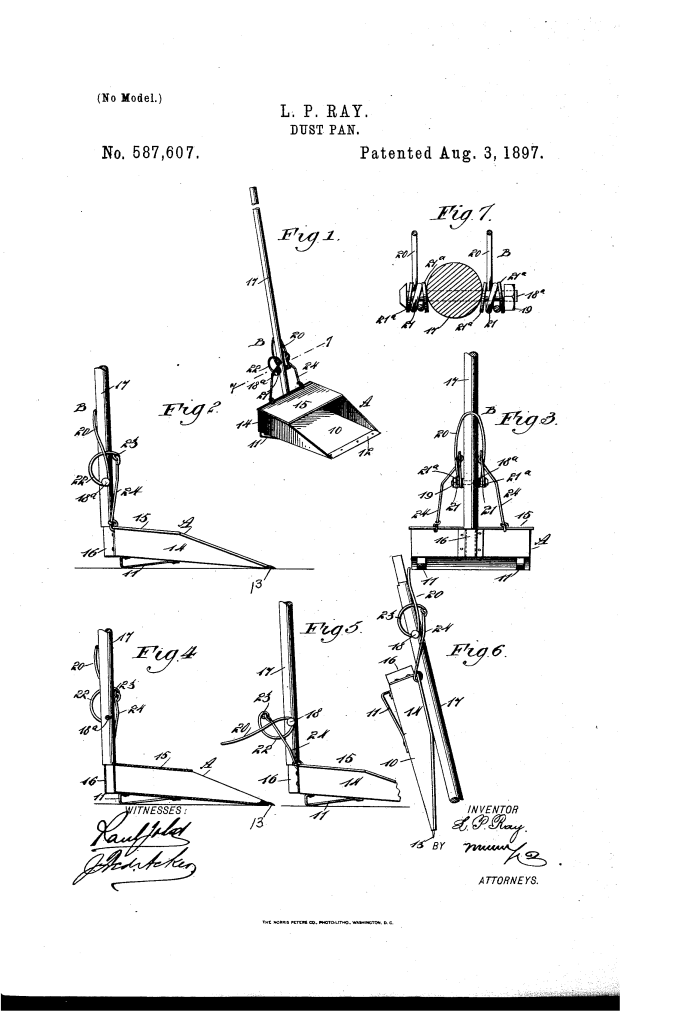

The patent by Lloyd P. Ray of Seattle, Washington, describes an improved Dust-Pan (Patent No. 587,607, 1897). The key objectives are to ensure the receiving edge lies close to the floor, use a stronger material for the edge, and provide a removable, adjustable handle with a spring fastening that allows the pan to be hung up when not in use.

Inventor Background: Lloyd P. Ray

Lloyd P. Ray was an African-American inventor who focused on practical solutions for household and domestic cleaning tools. His invention addresses the common ergonomic and functional flaws of ordinary dustpans—poor floor contact, weak edges, and awkward storage—by integrating a self-locking handle and a reinforced edge.

Invention and Mechanism

The pan features a reinforced edge and a unique, spring-tensioned handle assembly that locks the handle upright for use or flat for storage.

1. Pan Design (Key Innovation: Reinforced Edge)

- Body and Feet: The pan body (A) has feet (11) at the rear, giving the bottom a forward tip or inclination.

- Receiving Edge: A plate (12) made of steel or a similarly hard material is secured to the forward end of the pan bottom. This plate is thin and bent downward to form a curved surface (13).

- Function: The hard-material tip ensures the receiving edge is durable, and the downward-curved surface allows it to be brought into close engagement with the floor, preventing sweepings from escaping underneath.

2. Removable, Adjustable Handle

- Socket (16): A rectangular socket is formed at the back central portion of the pan.

- Handle (17) and Pins (18): The handle has a rectangular end that fits into the socket. Pins (18) are secured laterally to the handle near its lower end.

- Spring Fastening Device (B): Made of spring-wire, this is the core of the locking mechanism.

- Coils (21): The wire is bent to form coils that wrap around the handle’s pins (18).

- Loop (20) and Links (24): The wire is bent to form a loop (20) that engages the handle’s back, and the wire’s ends connect via links (24) to the upper rear edge of the pan.

- Operation (Locking): When the handle is inserted and the loop (20) is carried upward to engage the back of the handle, the coils (21) contract, coming under tension. This tension forces the loop to brace the handle, holding it securely in an upright position.

- Operation (Storage/Hanging): When the loop (20) is carried downward, the handle can be removed from its socket and placed flat against the pan body. The loop (20) itself then serves as a convenient hook for hanging the pan.

Concepts Influenced by This Invention

Ray’s dustpan design influenced subsequent cleaning tools by pioneering a combination of material optimization for edge wear and a spring-tensioned storage mechanism.

- Optimized Dual-Material Edges: The concept of using a thin, harder material (steel plate 12) for the floor contact edge while using a lighter material for the pan body influenced the design of modern:

- Commercial and Industrial Scoops: Which feature a replaceable metal or high-wear plastic leading edge.

- Utility Blades and Scrapers: Where a harder strip is bonded to a softer base for durability.

- Convertible Spring-Tension Hinge/Lock: The innovative use of the external spring-wire assembly (B) to serve three functions—locking the handle rigidly (tension), allowing handle removal, and providing a hanging hook—influenced the design of various consumer and utility accessories that require multi-functional articulation and storage:

- Folding Shovels and Mops: Mechanisms that use an external wire or spring to hold the handle rigid during use but release it for folding/storage.

- Improved Floor Engagement: The design that deliberately tips the pan forward and uses a curved leading edge to minimize the gap influenced the ergonomic design of all subsequent dustpans and floor cleaning scoops .