Phillip W. Cornwell’s Draft-Regulator (Patent No. 491,082, 1893) is an improved chimney damper and regulator for stoves and furnaces. Its main innovation was relocating the operating mechanism for the draft-controlling parts away from the most intense heat in the center of the flue to prevent the device from being burned out.

Invention and Mechanism

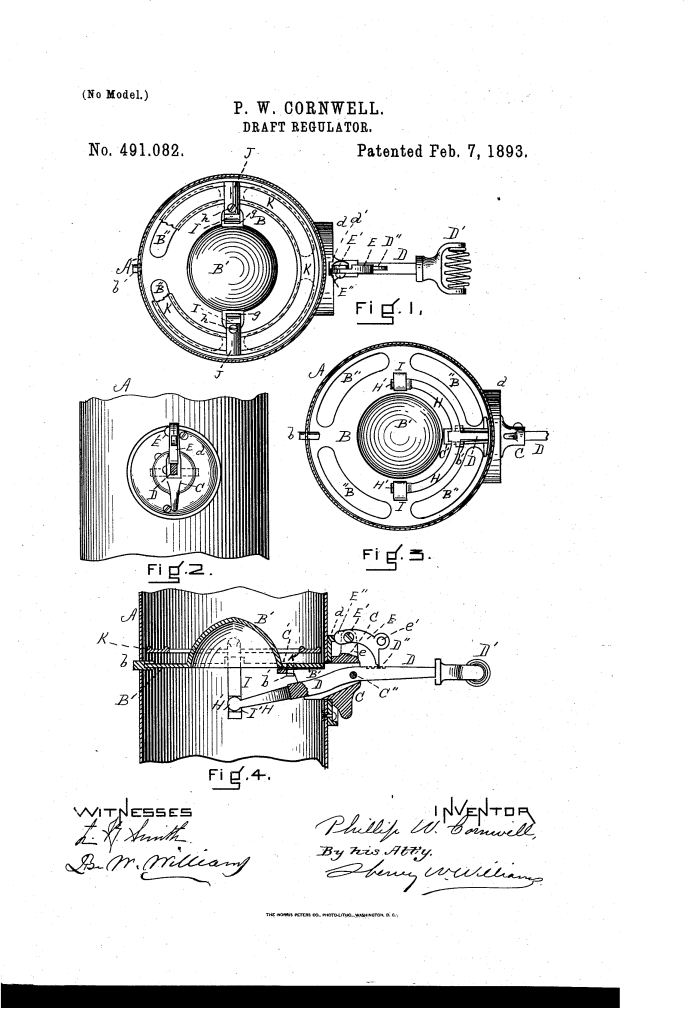

Cornwell’s device is a sophisticated two-part system designed for precise control over the flow of exhaust and air (draft) in a chimney flue:

- Main Damper (B): A central plate that rotates to fully open or close the flue, controlling the primary draft.

- Supplemental Damper (K): A ring that sits on the main damper and controls a series of slots (B′′) near the main damper’s edge. This allows for fine-tuning of the draft, often used when the main damper is closed or partially closed to maintain a slow, steady burn.

The primary improvement was the introduction of a semi-circular bar (H) rigidly attached to the operating lever. This bar engages two vertical rods (I) located off-center in the flue, thereby moving the mechanical connections out of the high-heat center where the inventor’s previous design was prone to failure. This change enhanced the durability and reliability of the regulator.

Historical Significance

The invention is significant as part of the broader 19th-century effort to improve the efficiency and safety of home heating.

- Fuel Efficiency: In the late 1800s, coal and wood were the dominant home heating fuels. Controlling the draft was critical to regulating burn rate. A strong, uncontrolled draft would waste fuel by allowing heat to escape too quickly, while a weak draft could lead to poor combustion and dangerous smoke buildup. Cornwell’s improved mechanism allowed householders to precisely regulate the air/fuel ratio, maximizing the heat output from expensive fuel.

- Technological Evolution: This patent is explicitly an improvement on an earlier patent by the same inventor. This iterative design process—where inventors continually filed new patents to fix shortcomings (like heat damage) in prior models—was characteristic of the rapid industrial innovation occurring during the era.

- The Inventor (Phillip W. Cornwell): While Cornwell doesn’t have the broad historical profile of an inventor like Loudin, his work is typical of the era’s specialized inventors and manufacturers. Brockton, Massachusetts, where he resided, was a burgeoning industrial center, and his focus on durable, practical hardware was aimed at the growing consumer market for domestic utilities.

Relation to Current Items

While Cornwell’s specific design for a mechanical flue damper isn’t commonly found in modern homes, the underlying principles are directly related to current heating and climate control technology:

- Manual Dampers: The basic function of a damper is unchanged. Wood-burning stoves and fireplaces still utilize manually adjustable dampers (often a simple revolving plate) in the stovepipe to regulate air flow and prevent excessive heat loss when the unit isn’t in use.

- Automatic Draft Control: The principle of regulated draft is central to modern forced-air furnaces and boilers. Instead of a manual lever, modern systems use electronic dampers and inducer fans to create a precisely controlled combustion environment. These systems electronically modulate air intake and exhaust to ensure maximum fuel efficiency and safety, a highly refined version of the “draft regulator” concept.

- Heat Shielding: Cornwell’s solution of moving the operating mechanism away from the intense heat is a fundamental engineering principle. Modern devices operating in high-temperature environments (like engine components or commercial furnace controls) use sophisticated heat shielding, insulation, or remote actuation to protect sensitive electronics and moving parts, directly addressing the durability problem Cornwell faced in 1893.