Display Rack (Richard Warren, No. 1,619,900)

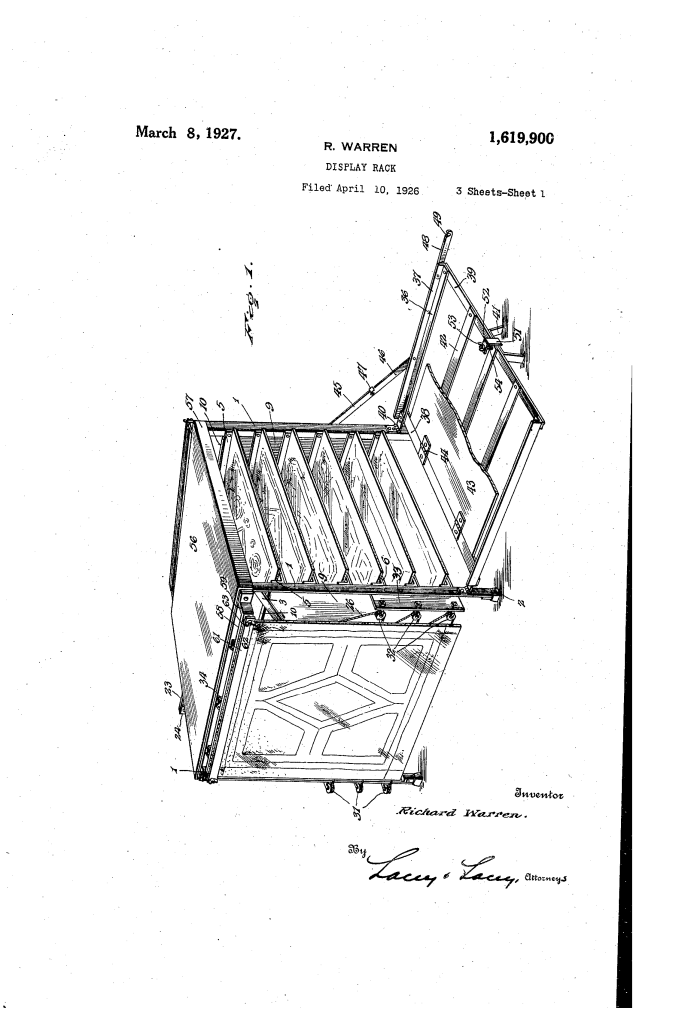

The patent by Richard Warren of Washington, D.C., describes an advanced Display Rack (Patent No. 1,619,900, 1927). This invention is a mechanical storage and exhibition system designed primarily for heavy rugs and tapestries. Warren’s primary objective was to eliminate the labor-intensive process of manually unrolling and spreading rugs for customers. His innovation features a multi-tiered shelf system equipped with weighted cable retractors, allowing individual rugs to be pulled out for inspection and automatically returned to their flat, protected storage position when released.

Inventor Background: Richard Warren

Richard Warren was an African American inventor and entrepreneur based in the District of Columbia during the mid-1920s. His 1927 patent reflects a deep understanding of the retail environment and industrial design. In the early 20th century, displaying large rugs required significant physical strength and often resulted in premature wear and tear on the merchandise. Warren’s engineering solution provided a way to professionalize the sales process, emphasizing merchandise preservation and labor efficiency. His design for a dust-proof, space-saving cabinet showcased a sophisticated approach to retail logistics.

Key Mechanical & Functional Systems

The rack utilizes a combination of gravity-based counterweights and mechanical clamps to manage large, heavy sheets of material.

1. The Multi-Tiered Shelf Structure (4, 5, 8)

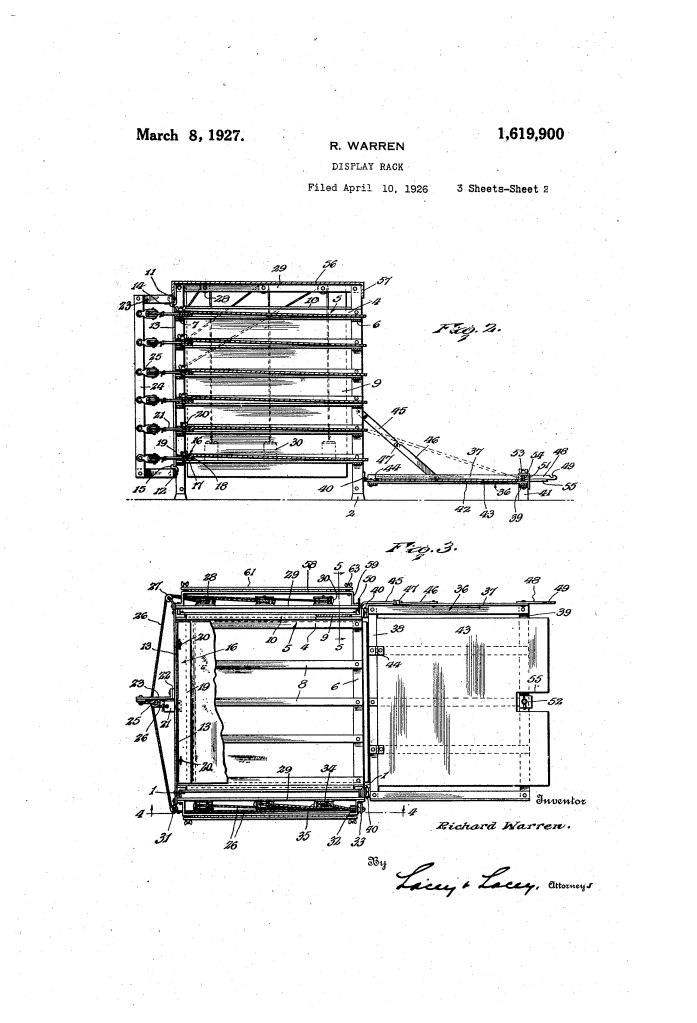

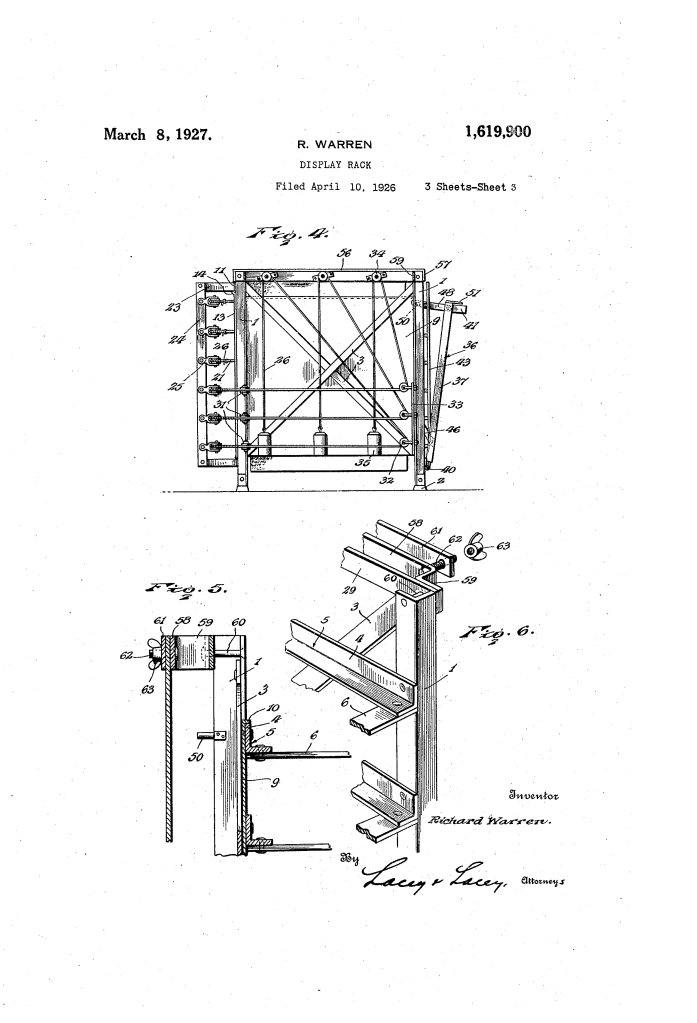

- Framework: The frame is built from rigid angle iron uprights (1) braced with diagonal bars (3).

- Shelves (5): A vertical series of shelves, each composed of side members (4) and flat bottom bars (8).

- Function: This structure allows rugs to be stored flat and spaced apart. This spacing enables a customer to see the patterns of multiple rugs simultaneously without needing to withdraw them all.

2. The Non-Piercing Rug Clamp (16, 17, 19)

- Clamping Bar (17): A bar equal to the width of the shelf with an upstanding flange (18).

- Clamping Bolt (20): Wing nuts are used to tighten a secondary bar (19) against the first.

- Innovation: Unlike standard racks that used sharp spurs to grip the rug, Warren’s design used a pressure-based clamp. This secured the rug firmly without piercing or damaging the delicate fibers.

3. Weighted Retraction System (25, 26, 30) (Key Innovation)

- Cables (26): Each rug clamp is attached to a flexible cable.

- Pulley Network (25, 27, 28): The cables are trained over a complex series of pulleys at the rear and sides of the frame.

- Counterweights (30, 35): The cables terminate in weights suspended at the sides of the rack.

- Function: When a salesman pulls a rug forward, the weight is lifted. Once the rug is released, gravity pulls the weight back down, automatically retracting the rug into its shelf.

4. The Convertible Front Closure (36, 43, 51)

- Hinged Frame (36): A rectangular frame is hinged at the bottom of the rack.

- Closure Plate (43): A plate that rests on the frame when lowered and closes the rack when raised.

- Secondary Display: When the frame is lowered, it can be locked into a horizontal position. A clamping member (51) at the front of this frame can hold a rug in a fully extended position for long-term inspection without the salesman having to hold it.

Improvements Over Standard Rug Displays

| Feature | Standard Manual Display | Warren’s Mechanical Rack |

| Labor | Required two people to unroll and roll rugs. | Single-operator pull-and-release system. |

| Wear & Tear | Rugs were often stepped on or dragged. | Rugs stay on individual shelves; retracted flat. |

| Dust Protection | Rugs were exposed to floor dust and light. | Enclosed casing with top, side, and rear plates. |

| Safety | Rugs were pierced by metal spurs. | Pressure clamps (16) prevent damage to materials. |

Significance to Engineering and Retail Design

Richard Warren’s display rack influenced the development of merchandise management systems and retractable industrial storage.

- Gravity-Assisted Automation: The use of counterweights to manage heavy loads is a foundational principle in industrial elevator and window sash design, applied here to the retail sector.

- Dust-Exclusion Engineering: By designing a cabinet with slidable side plates (9) and a flanged top (56), Warren anticipated the clean-room and dust-controlled environments necessary for modern archival storage.

- Ergonomic Retail: The “pull-out” shelf concept is a direct ancestor of the sliding drawers and organizers found in modern high-end cabinetry and retail showrooms.

- Aesthetic Concealment: Warren’s provision to hang a decorative rug on a side bar (58) to hide the weights and cables shows a sophisticated eye for visual merchandising and industrial aesthetics.