The Invention: A “Direct-Acting Steam Engine”

The patent, US394047A, granted to Frank Winn of Dallas, Texas on December 4, 1888, is for a new kind of direct-acting steam engine.

A direct-acting steam engine is one where the piston’s reciprocating motion (back and forth) is directly converted into the rotational motion of a main shaft, without the use of a traditional connecting rod and crank mechanism.

Key Features of the Invention:

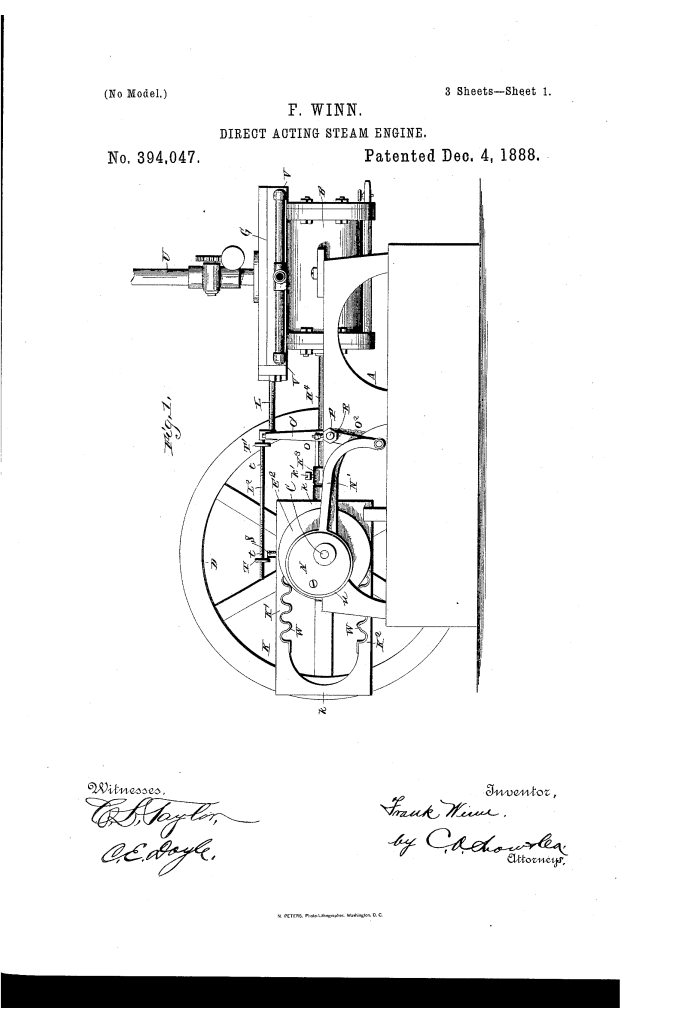

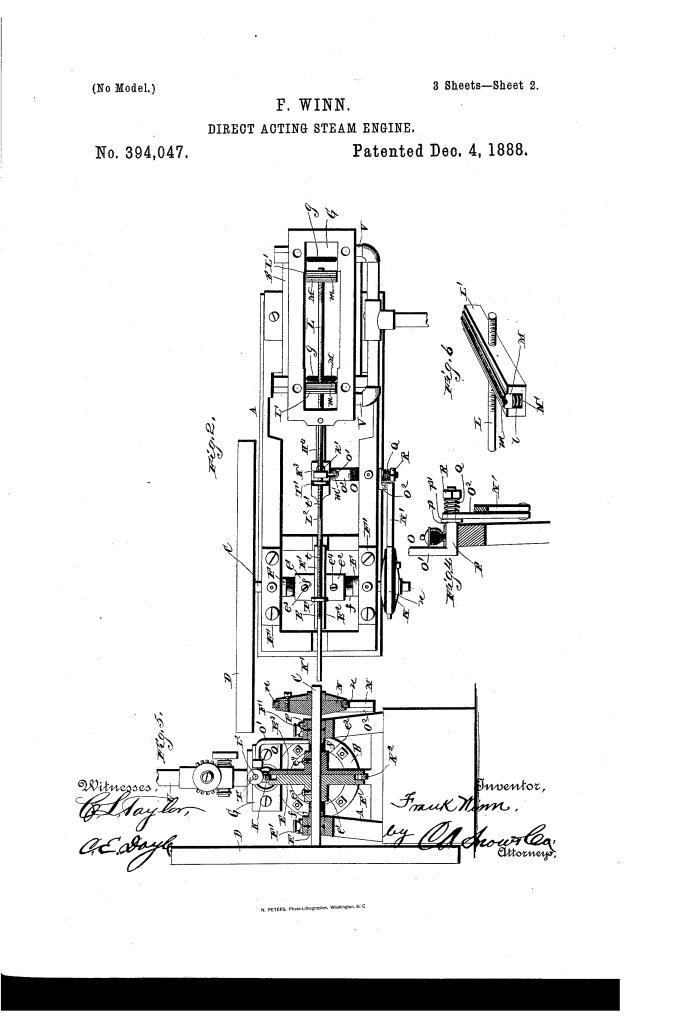

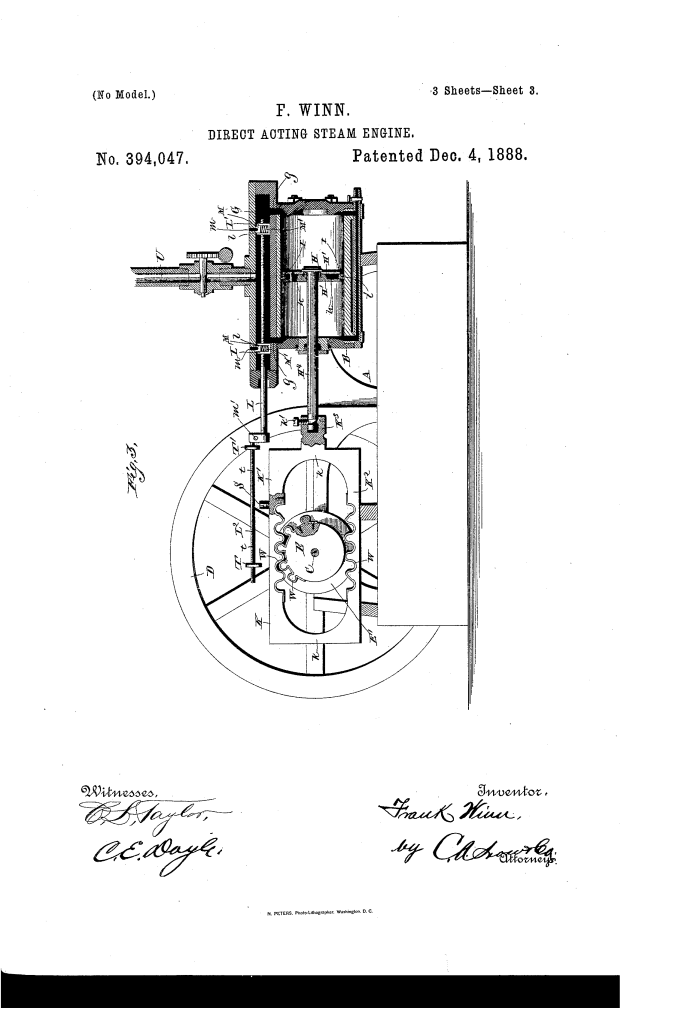

- Piston and Rack-and-Pinion System: The engine uses a piston-rod that is attached to a “rack-frame” (K). This rack-frame has teeth on both its upper and lower sides.

- Segmental Gear Wheel: The rack-frame’s teeth engage with a “segmental gear-wheel” (E) on the main shaft (C). As the piston moves in one direction, the upper rack engages the gear, and as it reverses, the lower rack takes over, continuously turning the main shaft.

- “Instantaneous Cut-Off” Mechanism: This is the most innovative part of the invention. The patent describes a separate, faster mechanism for controlling the steam.

- A “finger” (S) on the piston’s rack-frame strikes adjustable “stops” (T) on the valve-stem (L) at the very end of each stroke.

- This action forces the valves to immediately reverse the steam flow.

- “Divided Lever” and Friction Clutch: The engine also has a unique lever system (O) that connects the main shaft’s eccentric (N) to the valve-stem. The lever is made of two separate arms that are held together by a tension spring and a nut.

- This design allows the lever to operate the valves in the “ordinary” way for most of the stroke.

- However, when the “instantaneous cut-off” finger strikes the valve-stem stop, the lever’s two arms can move independently, preventing the sudden, forceful action from damaging the more conventional eccentric-driven valve system.

- Cushioning Effect: The rapid, “instantaneous” reversal of steam creates a “cushion of steam” between the piston and the end of the cylinder. This cushions the piston’s motion, preventing the “hammer or knock” that would otherwise occur when the rack changes direction. This cushioning effect is the core purpose of the unique cut-off system.

Significance of the Invention and Inventor

Significance on Society:

- Solving a Core Engineering Problem: Frank Winn was addressing a fundamental problem with early direct-acting engines: the harsh impact and vibration that occurred at the end of each piston stroke. This “hammering” effect was not only noisy but also caused wear and tear on the machinery. His invention, with its ingenious “cushioning” mechanism, provided a new way to solve this problem.

- Incremental Innovation: While not as famous as James Watt or other major inventors, Winn’s patent represents the continuous, incremental innovation that propelled the Industrial Revolution forward. Each patent, no matter how small, contributed to a more efficient, reliable, and durable machine. His design shows a sophisticated understanding of mechanical principles, particularly the need to coordinate different mechanisms (the rack-and-pinion and the valve timing) to achieve a smooth operation.

- A “Texas Inventor”: The patent lists Frank Winn as being from Dallas, Texas, which at the time was a rapidly growing city but not yet a major industrial center. This shows that the culture of innovation was widespread across the United States, not just confined to the industrial heartlands of the Northeast. It highlights the entrepreneurial and inventive spirit that was a hallmark of the era.