Dinner-Pail (John Robinson, No. 356852)

The patent by John Robinson of Coal Valley, West Virginia, describes an improvement in Dinner-Pails (Patent No. 356852, 1887). The invention is a multi-compartment lunch container designed specifically for workmen, featuring an integrated heating system that allows the user to warm both their beverage and their food simultaneously using a small lamp.

Inventor Background: John Robinson

John Robinson was an African-American inventor living in the coal mining regions of West Virginia in the late 19th century. His invention was a direct response to the harsh working conditions of miners and laborers who spent long hours away from home. Standard lunch pails of the time offered no way to keep food warm; Robinson’s design utilized basic thermodynamic principles to provide a hot meal in the field, representing a significant improvement in the quality of life for industrial workers.

Invention and Mechanism (Simplified)

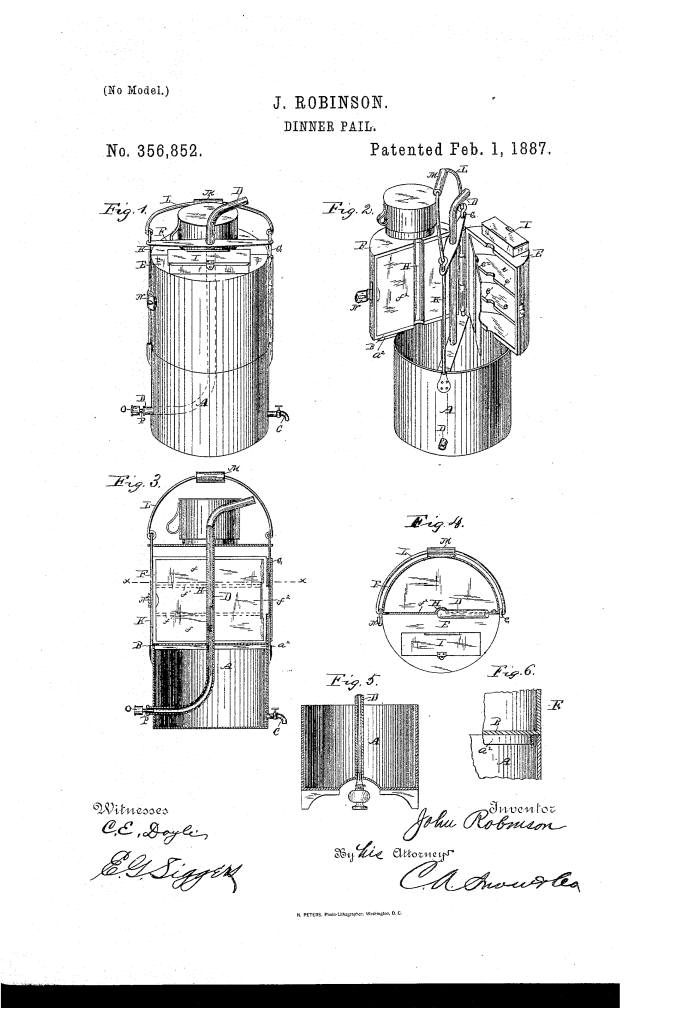

The dinner-pail is a cylindrical tower consisting of a base for liquids and two hinged upper sections for solid food, all connected by a central heating flue.

1. The Lower Liquid Section (A)

- Design: The base of the pail (A) is a cylindrical reservoir meant to hold tea, coffee, or soup.

- Faucet (C): A small faucet at the bottom allows the worker to pour their drink without opening the entire container and losing heat.

2. The Heating Tube (D) (Key Innovation)

- Heat Exchange: A vertical heating-tube (D) passes through the center of the base and extends upward between the food compartments.

- Operation: To warm the meal, the worker inserts the spout of a small lamp (O) into the lower end of the tube.

- Function: As the heat and products of combustion rise through the tube, they pass through the liquid in the base and then between the upper food sections, warming everything in the pail simultaneously.

3. Hinged Food Compartments (E and F)

- Modular Access: Above the base are two semi-cylindrical sections (E and F) united by a pivotal rod (G).

- Recesses (H): Each section has a semicircular notch (H) on its inner side so they can close tightly around the hot heating tube.

- Shelves and Doors: Each section is divided into horizontal compartments with their own hinged doors. This allows the worker to access specific parts of their meal (e.g., meat in one, bread in another) while keeping the rest protected.

4. Safety and Portability

- Interlocking Flanges: To prevent the food sections from swinging open accidentally, Robinson added a semicircular flange to the bottom of the upper sections.

- Function: The flange fits inside the rim of the base. The sections must be lifted vertically along the rod (G) before they can be swung outward, ensuring the pail stays securely closed during transport.

- The Bail (L): A wire handle with a wooden grip is attached to the central rods, making the entire “tower” easy to carry to the job site.

Concepts Influenced by This Invention

Robinson’s dinner-pail influenced the development of portable heating technology and modular food storage.

- Portable Heat Exchange: The use of a central flue to warm a surrounding container is a principle found in early steam boilers and modernized in products like self-heating cans and high-efficiency camping stoves.

- Vertical Modular Storage: The “stacked” design, which separates liquids from solids while utilizing a single vertical axis for structure and heat, is a precursor to the modern bento box and insulated tiered lunch jars (like those made by Zojirushi).

- Workplace Ergonomics: By including a matchbox (I) and a faucet, Robinson addressed the specific logistical needs of a 19th-century laborer, pioneering the idea of “all-in-one” utility gear.

- Mechanical Interlocks for Safety: The lift-to-open flange mechanism is a fundamental mechanical safety feature used in various types of industrial lids and containers to prevent accidental discharge or opening under vibration.