Device for Sharpening Edged Tools (Walter Purdy, No. 609,367)

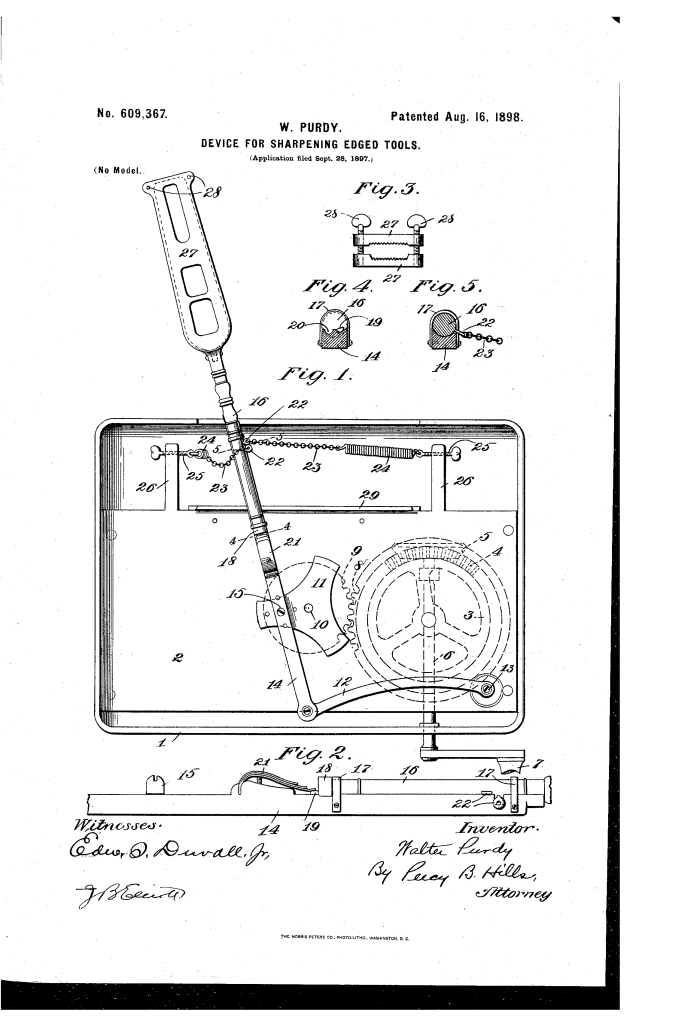

The patent by Walter Purdy of Somerset, Pennsylvania, describes an advanced Device for Sharpening Edged Tools (Patent No. 609,367, 1898). This invention is an improvement upon his earlier razor sharpener (Patent No. 570,337) and aims to not only move the tool in an oval or elliptical path but also to automatically turn the tool over (flip the edge) at each end of the stroke, ensuring the tool is always moved with its edge leading.

Inventor Background: Walter Purdy

Walter Purdy was an inventor specializing in precision mechanical tools for consumer and domestic use. His commitment to refining his initial patent demonstrates a strong technical focus on automating the complex, skilled hand motions required for professional sharpening, thereby enhancing the quality and accessibility of the tool.

Invention and Mechanism

The device maintains the elliptical motion of the previous patent but adds a spring-tensioned rotary system to flip the blade automatically.

1. Elliptical Motion Mechanism

- Drive Train: A handle (7) drives a gear train (3, 9, 14) which rotates a star-wheel (11).

- Main Arm Linkage: A lever (12) is eccentrically connected to the star-wheel (11). The main arm (14) is pivotally connected to the lever (12).

- Function: This linkage converts the rotary motion into the desired oval or elliptical path for the end of the main arm (14).

2. Automatic Reversing (Flipping) Mechanism (Key Innovation)

- Tool-Carrying Arm (16): This arm, which holds the razor (23) in the tool-holder (27), is rotatably mounted within the main arm (14) via suitable collars.

- Rotational Limit: A pin (19) on the inner end of arm (16) engages one of two sockets (20) in the main arm (14), limiting the arm’s rotation to the necessary $180^\circ$ flip. A leaf-spring (21) holds the pin in either socket against slight resistance.

- Spring-Tension Flipping System:

- Eyes (22) and Cords/Chains (23): Two eyes (22) are fixed to one side of the rotating arm (16). Cords/chains (23) connect these eyes to coiled springs (24).

- Fixed Brackets (26): The other ends of the springs (24) are fixed to brackets (26) on the stationary plate (2).

- Operation (Flipping): As the main arm (14) reciprocates in its elliptical path:

- Stroke Right: The right-hand spring (24) relaxes, and the left-hand spring (24) is stretched.

- Limit of Stroke: Just as the arm reaches its furthest point, the tension of the left-hand spring overcomes the resistance of the leaf-spring (21), snapping the arm (16) and the razor $180^\circ$ into the opposite socket (20).

- Return Stroke Left: The process reverses, and the right-hand spring snaps the arm back, ensuring the razor’s edge is always presented in the direction of movement.

Concepts Influenced by This Invention

Purdy’s improved sharpener influenced subsequent mechanical designs by integrating complex motion synthesis with dynamic, self-actuated reversal using differential spring tension.

- Dynamic Spring-Actuated Reversal: The core concept of using opposing, fixed, adjustable springs (24) to store and release enough energy to mechanically overcome a latch (spring 21) and rotate a tool at the endpoint of its travel influenced the design of:

- Automated Tool Changers/Flippers: Industrial mechanisms that require a tool head or component to flip $180^\circ$ at the end of a stroke, often relying on spring or hydraulic tension rather than dedicated motor drive.

- Reversing Mechanisms: Consumer or utility devices that require a repetitive, oscillating action where the working element must synchronize its flip with its linear path.

- Integrated Dual-Motion System: The successful integration of the elliptical motion linkage and the rotational flipping mechanism into one synchronized machine reinforced the viability of mechanizing complex, multi-axis, skilled manual tasks for consumer use.

- Adjustable Tensioning: The provision for regulating the flipping force via adjustable screw-rods (25) on the springs influenced the design of mechanical systems where the force required for a cycling action must be precisely calibrated to overcome component friction or wear.