Device for Sharpening Edged Tools (Walter Purdy, No. 570,337)

The patent by Walter Purdy of Somerset, Pennsylvania, describes an apparatus for sharpening razors and other edged tools. The primary object is to provide a mechanical device that moves the article to be sharpened over the hone in the form of an oval or ellipse, thereby imitating the ideal motion previously imparted by skilled hand sharpening.

Invention and Mechanism

The device is a complex mechanical system that converts rapid rotary motion into a precise, elliptical motion for the tool, while providing a cushioned base for the sharpening stone.

1. Elliptical Motion Mechanism

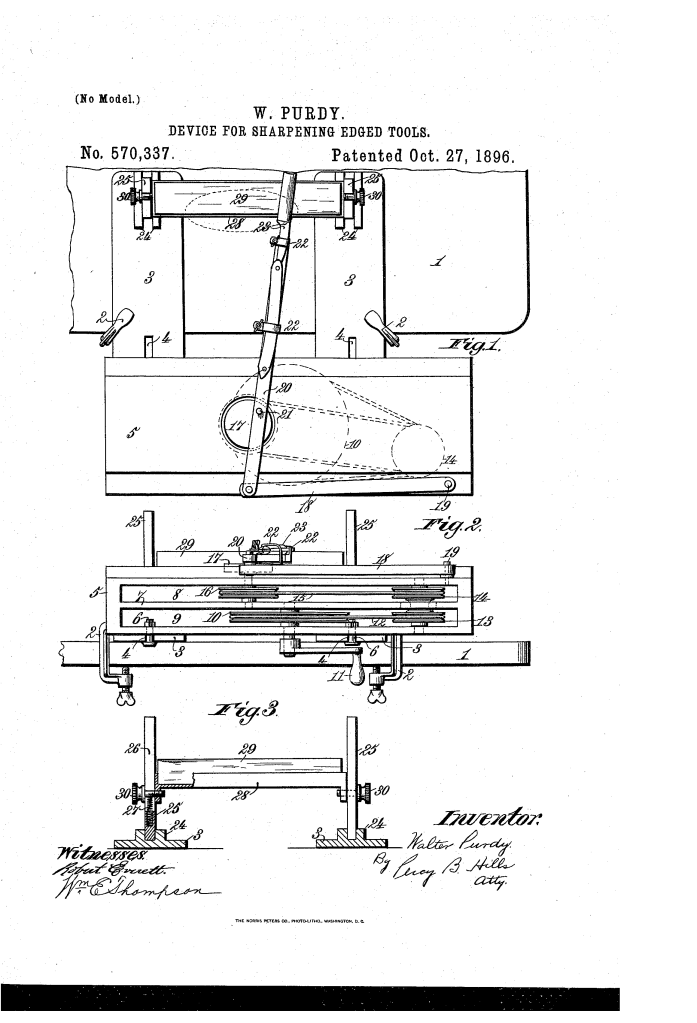

- Frame and Power Train: A frame (5) containing a series of wheels (10, 13, 14, 16, 17) is mounted to a support (1). A handle (11) drives the large wheel (10), which, through a series of belts (12, 15) and intermediate wheels (13, 14, 16), imparts a much more rapid rotary motion to the final wheel (17).

- Linkage for Ellipse:

- Wheel (17): The final, fast-rotating wheel, mounted in the top of the frame.

- Arm (20): This arm carries the tool (razor 23) in clamps (22) at its free end. It is connected eccentrically (off-center) to the wheel (17) at point (21).

- Lever (18): Pivoted at one end (19) to the frame, its free end is pivotally connected to the arm (20).

- Function: The eccentric rotation of wheel (17), combined with the constraining pivot of the lever (18), forces the free end of the arm (20) (and the tool) to travel in a specific, recurring oval or elliptical path over the hone.

2. Yielding Hone Support

- Uprights (25): These are longitudinally movable in guideways (24) on the base boards (3). They are slotted (26) for most of their length.

- Springs (27): Coiled springs are seated in the lower ends of the slots (26).

- Hone Support (28): The hone (29) is carried by this support, which is held between the uprights (25) by set-screws (30). These set-screws rest directly upon the upper ends of the springs (27).

- Function: This arrangement provides a yielding support for the hone. The spring support compensates for the rigidity of the motion arm (20), ensuring the hone maintains proper contact with the blade at all times.

Historical Significance and the Inventor

Walter Purdy’s 1896 patent is an excellent example of mechanizing skilled labor during the late 19th century.

- Mechanizing the Hone: Achieving a perfect, consistent edge on tools like razors required a specific, complex, figure-eight or elliptical motion—a skill honed through years of practice. Purdy’s invention aimed to automate this precise, complex hand motion, making professional-quality sharpening accessible to the general public or to barbers without extensive training.

- The Yielding Support: The inclusion of the spring-mounted hone demonstrated a sophisticated understanding of tool physics: rigid mechanisms often fail because they can’t account for slight variations in the tool’s curvature or the hone’s surface. The yielding support ensured uniform pressure across the entire length of the blade, essential for a fine edge.

- The Inventor (Walter Purdy): Purdy, residing in Somerset, Pennsylvania, contributed to the wave of consumer and domestic tools designed to bring industrial efficiency and precision into everyday life.

Core Concepts Utilized Today

Purdy’s device uses mechanical principles that are fundamental to modern industrial finishing and motion control.

- Complex Motion Synthesis (Elliptical Motion): The use of a crank (eccentric connection) and constrained linkage (lever 18) to convert simple rotary motion into a complex, non-circular path is a classic engineering solution. This principle is used in modern industrial polishing, lapping, and orbital sanding/finishing machines to ensure uniform abrasion over a large surface area.

- Spring-Compensated Tooling: The design of a tool platform or grinding surface that rests on springs to maintain constant, uniform contact pressure against a rigid tool holder is a core principle in modern CNC grinding machines, diamond lapping fixtures, and optical polishing equipment. This ensures that the grinding force is always consistent regardless of minor imperfections in the workpieces.

- Geared Speed Amplification: The series of belts and wheels to impart a rapid rotation (speed amplification) to the working component from a slower, hand-cranked input is a technique still found in various manual and low-power grinding tools, like small hand-cranked bench grinders.