Device for Rolling Cigarettes (James A. Sweeting, No. 594,501)

The patent by James A. Sweeting of New York, N.Y., describes an improved Device for Rolling Cigarettes (Patent No. 594,501, 1897). The objective is to provide a simple, effective tool that enables the ordinary user to roll cigarettes conveniently and perfectly, ensuring a properly formed product with a securely adhered wrapper.

Inventor Background: James A. Sweeting

James A. Sweeting, a subject of the Queen of Great Britain residing in New York, was an inventor contributing to the consumer market for personal-use products. His invention is part of a wave of late 19th-century devices that automated or simplified tasks previously done by hand, capitalizing on the rising popularity of “roll-your-own” tobacco.

Invention and Mechanism

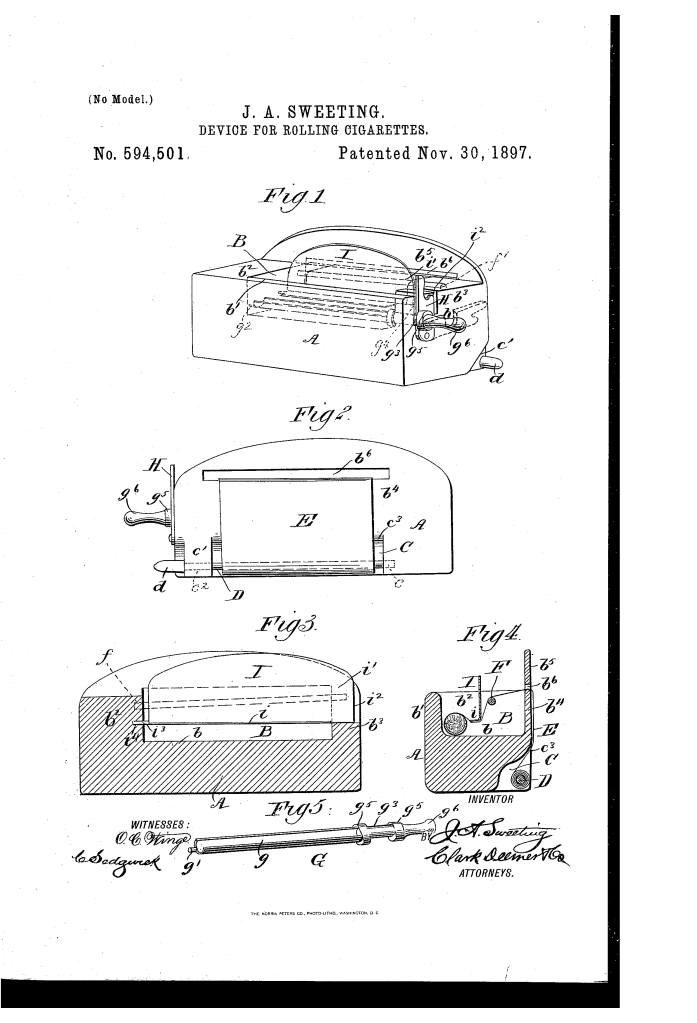

The device is a hand-held block that integrates a paper supply, a mold (mandrel), and internal guides to perform a precise rolling action.

1. Frame and Paper Feed

- Frame (A): An approximately rectangular block or body, intended to be hand-held. It has a top chamber (B).

- Paper Roll (E): A roll of cigarette paper mounted on a pin or shaft (D) at the rear of the block.

- Feed System: The paper feeds over a curved edge (

) of a rear recess (C), up against the back wall (

), through a slot (

), and forward over a transverse roller (F) at the top of the chamber (B).

2. Rolling and Forming Mechanism (Key Innovation)

- Removable Mandrel/Former (G): This is the core mold, featuring a concaved semicylindrical stem (). It is mounted to rotate within bearing slots and recesses in the side walls of the chamber. A handle (

) projects from the side for manual rotation.

- Operation: The tobacco is filled into the concaved stem (

), and the edge of the paper is wrapped around it. By turning the handle (), the mandrel revolves, perfectly and conveniently forming the cigarette.

- Locking: A pivoted catch (H) engages the mandrel’s bearing portion to lock it in its operative position.

- Operation: The tobacco is filled into the concaved stem (

- Guide-Plate (I) / Supplementary Former: A vertical plate arranged transversely within the chamber, between the mandrel (G) and the guide-roller (F). Its bottom edge () is turned at a right angle to form a flange.

- Function: The paper is guided under the angular flange (

) before reaching the mandrel. This plate co-operates with the mandrel to ensure the tobacco is compressed and the paper is wrapped tightly and uniformly.

- Function: The paper is guided under the angular flange (

3. Sealing

- Function: After rolling, the user wets the exposed paper along the line of the roller (F). Further turning of the mandrel creates tension that separates the paper cleanly, and the wet portion of the wrapper adheres to the formed cigarette, preventing unwinding.

Concepts Influenced by This Invention

Sweeting’s cigarette roller influenced subsequent designs for manual and mechanical cigarette rolling by standardizing the mandrel-and-guide method for tight, uniform rolling.

- Mandrel Rolling Automation: The fundamental concept of using a rotating semicylindrical mold (mandrel G) in conjunction with a fixed guide-plate (I) to compress material and wrap a sheet is the basis for most subsequent manual cigarette rolling devices and the internal mechanics of industrial cigarette machines. This ensures high density and a clean, straight form.

- Integrated Paper Feed: The design’s inclusion of an integrated, dedicated paper roll holder and feed path influenced the design of various consumer and commercial wrapping tools, where the material supply is mounted directly on the tool.

- Sequential Compression and Forming: The paper being guided under the flanged edge () before being seized by the mandrel (G) is a simple, effective instance of sequential compression, ensuring the tobacco is properly packed before the paper is wrapped over it. This principle is key in modern packaging and forming machinery.