Device for Removing and Inserting Taps (William Hearns, No. 1,040,538)

The patent by William Hearns of Washington, D.C., describes a Device for Removing and Inserting Taps and Plugs in Water-Mains (Patent No. 1,040,538, 1912). This invention is a specialized pressurized chamber—a “tapping machine”—that allows municipal workers to remove old pipes or insert new plugs into main water lines without shutting off the water supply to the rest of the city.

Inventor Background: William Hearns

William Hearns was an African American inventor living in the nation’s capital during the early 20th century. His invention addressed a major logistical challenge for growing cities: the “shut-off.” Before reliable tapping machines, repairing a single leak often required turning off water for entire blocks, causing significant disruption. Hearns’s design provided a “closed chamber” solution that contained the pressure of the water main, allowing a technician to work safely and efficiently. His patent demonstrates a sophisticated mastery of fluid pressure containment and mechanical tool-switching.

Invention and Mechanism (Simplified)

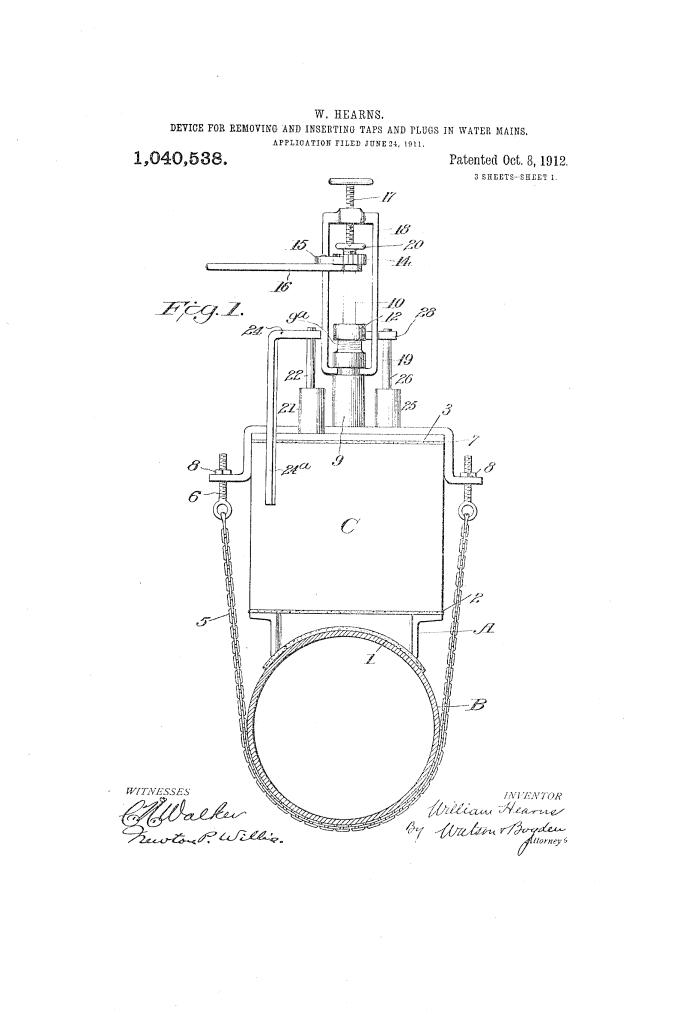

The machine creates a temporary, watertight room over the pipe where tools can operate under pressure.

1. The Casing and Saddle (A, C)

- The Saddle (A): A metal frame with a curved base that sits directly on the pipe ($P$). Because pipes come in different sizes, Hearns designed the saddle to be interchangeable.

- The Casing (C): A rectangular box that sits on top of the saddle.

- Function: Once secured by chains (5) and gaskets, the saddle and casing create a watertight chamber around the section of the pipe to be repaired.

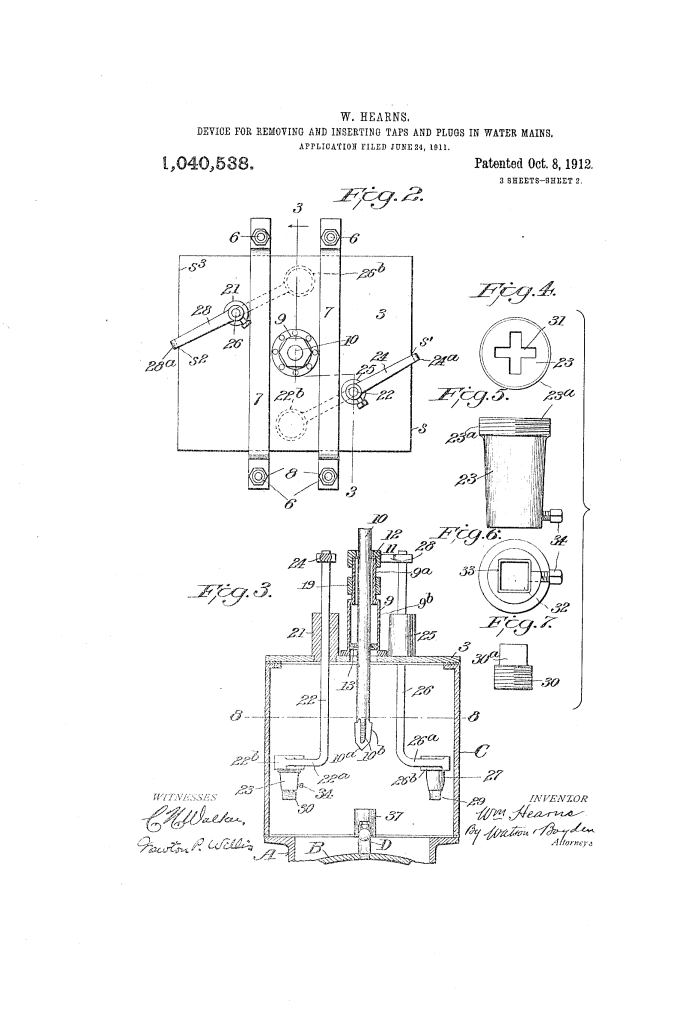

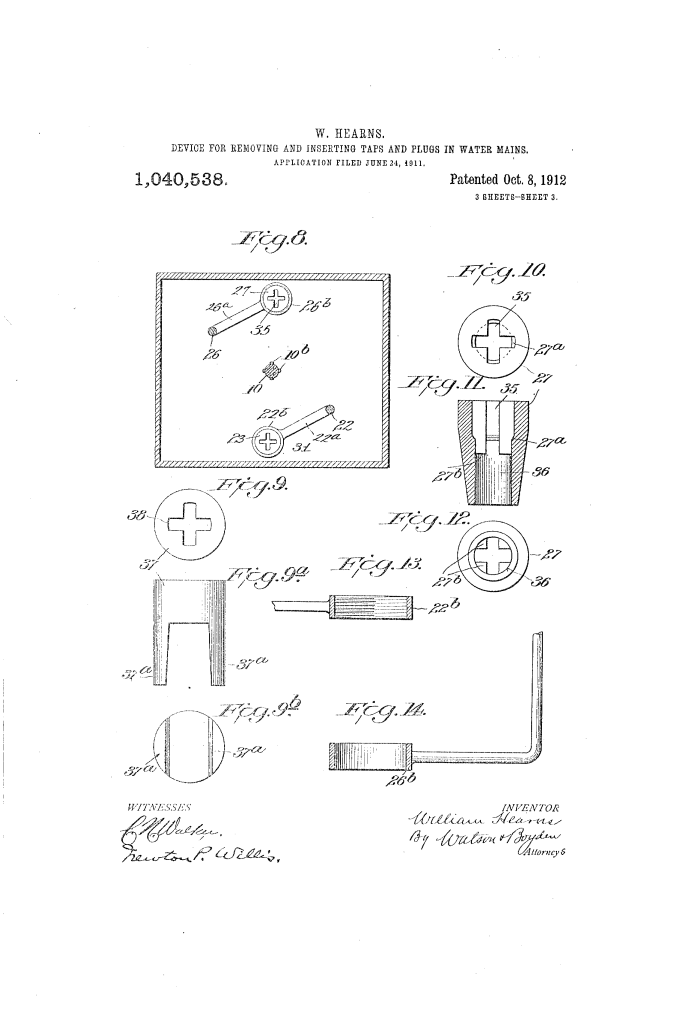

2. The Multi-Purpose Tool (10)

- Design: A central rod (10) that passes through a stuffing box (11) in the top of the casing to prevent leaks.

- Function: This single tool is “triple-threat.” It features a point for drilling, threaded wings ($10^b$) for tapping (cutting threads into the pipe), and serves as a wrench to turn plugs into place.

- Mechanical Advantage: It is operated by a ratchet (14) and lever (16) for heavy turning and a feed screw (17) to push the drill into the thick iron of the main.

3. The Swing-Arm Holders (22, 26) (Key Innovation)

Inside the chamber, Hearns placed two rotating arms that the worker can control from outside using levers ($24, 28$).

- The Threaded Plug Holder (22): This arm carries a new metal plug ($30$).

- The Emergency Plug Holder (26): This arm carries a wooden emergency plug (29).

- Function: If an old tap is removed and the hole is too corroded to take a metal plug immediately, the worker can swing the emergency arm into place and drive a wooden plug into the hole to stop the leak temporarily.

4. The Process of “Hot Tapping”

- The machine is clamped to the pipe while the water is still running.

- The tool (10) unscrews the old pipe tap ($D$).

- The water pressure pushes the tool and old tap upward.

- The worker swings the holder (22) to center a new plug over the hole.

- The tool is lowered to screw the new plug in, sealing the pipe.

Concepts Influenced by This Invention

William Hearns’s machine influenced the field of utility engineering and under-pressure maintenance.

- Hot Tapping Technology: The core principle of Hearns’s invention—working on a pressurized system without a shutdown—is the foundation of modern “Hot Tapping” and “Line Stopping” used globally in water, oil, and gas industries.

- Tool Redundancy and Safety: The inclusion of a dedicated emergency plug arm is a classic engineering fail-safe. It recognized that field conditions are unpredictable and provided a manual “plan B” within the automated system.

- Pressure-Sealed Actuation: The use of stuffing boxes and external levers to manipulate internal parts influenced the design of various industrial valves and underwater robotics, where a mechanical action must be performed across a pressure barrier.

- Modular Infrastructure Tools: By making the saddle (A) a separate, interchangeable part, Hearns pioneered the “universal platform” approach, reducing the amount of heavy equipment a utility crew needed to carry to a job site.