The patent by Clatonia Joaquin Dorticus of Newton, New Jersey, describes a novel device for applying coloring liquids (ink or stain) to the edges or sides of the soles or heels of shoes. The primary goal is to produce a bright, professional finish on these parts of the footwear while preventing staining of the soft upper leather (vamp) or the bottom of the sole, saving time and improving product quality.

Invention and Mechanism

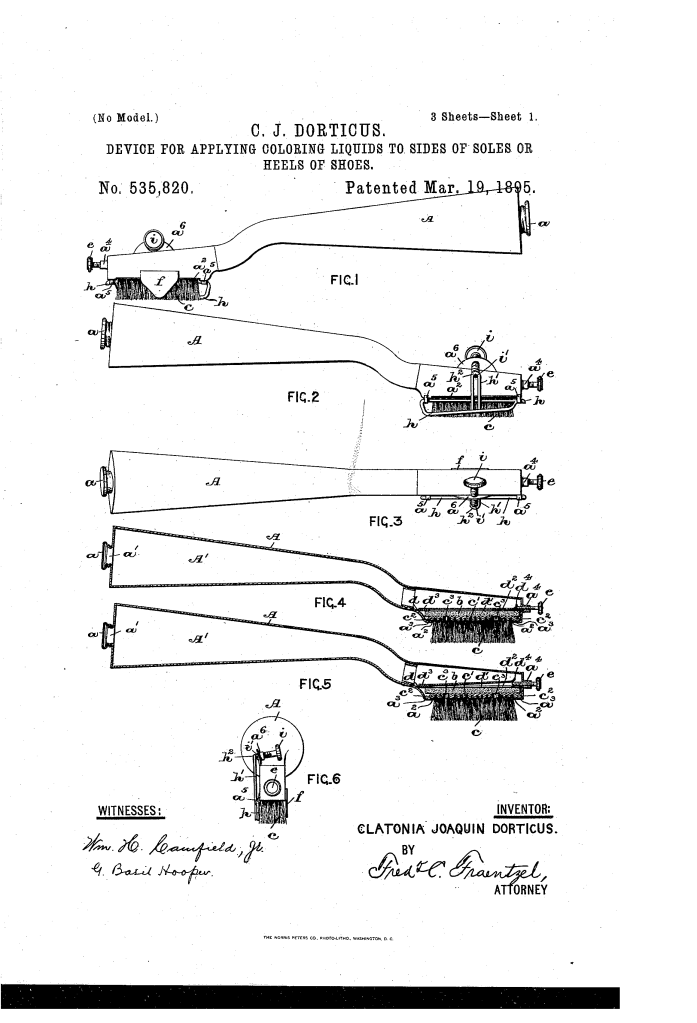

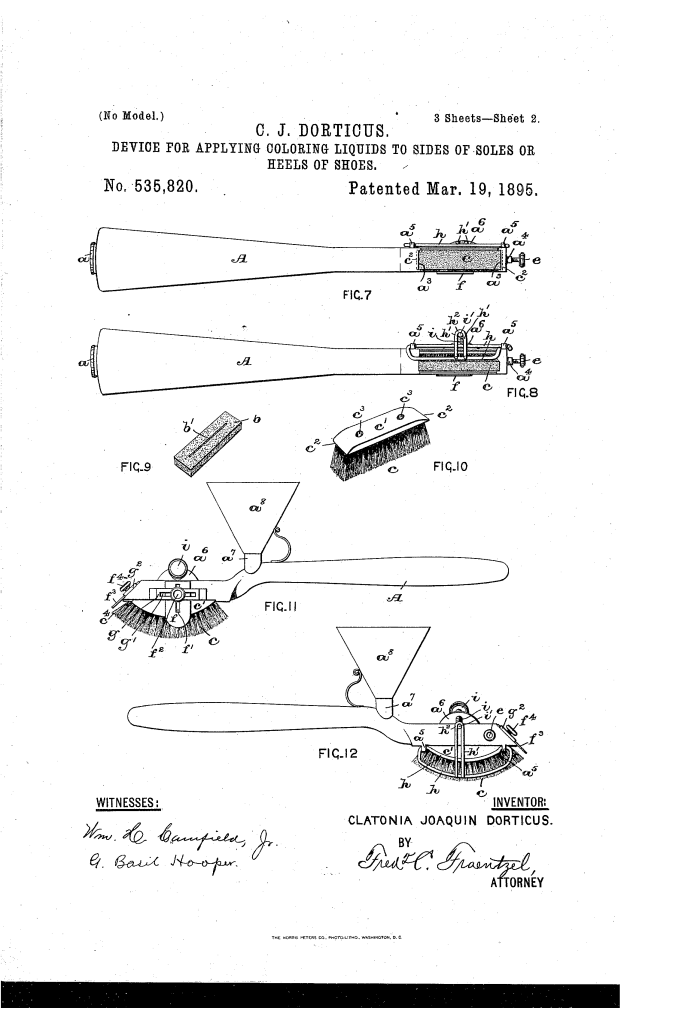

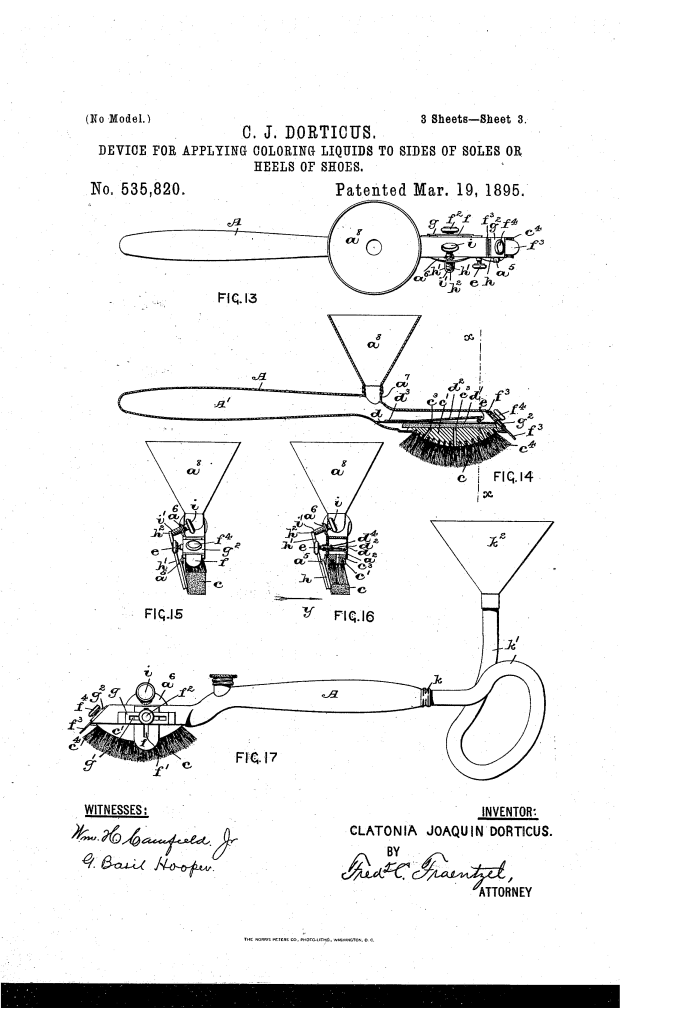

The device is a self-feeding, hand-held brush featuring multiple mechanisms for fluid regulation, brush width adjustment, and precision guiding.

1. Self-Feeding and Flow Control

- Hollow Handle/Reservoir (A): The handle is made of sheet metal and is shaped to serve as a reservoir (A′) for the coloring liquid.

- Brush (C) and Pad (b): A brush is removably arranged in an opening (a3) in the handle. The brush has a solid back (c′) with perforations (c3). A slitted pad (b) sits over the brush back.

- Function: The slitted pad and perforated brush back conduct the fluid from the reservoir down to the bristles.

- Valve and Regulator: A spring plate (d2) is arranged over an opening (d′) in a plate (d) inside the handle, serving as a valve.

- Adjusting Screw (e): An adjusting screw in the handle’s end or side is used to push against the valve plate (d2).

- Function: The operator can turn the screw (e) to raise or lower the valve plate, thereby regulating the flow of liquid onto the pad and into the brush bristles, or closing the valve entirely when not in use.

2. Precision and Safety Features

- Guide Plate (f): A guide plate, rounded at its lower end, is secured to the side of the holder (A).

- Function: This plate slides precisely in the joint formed by the sole and the shoe vamp. This prevents the liquid from getting onto the soft upper leather, even if the operator moves the brush quickly. It can be permanently fixed or vertically/sideways adjustable via a slot (f2) and set screw (f′).

- End Guide Plate (f3): A similar guide plate is secured to the end of the brush holder.

- Function: When coloring the heel, this plate prevents the brush end from spreading liquid onto the upper leather at the sides of the heel.

3. Brush Width Compression

- Compression Device (h): A wire frame (h) is pivotally arranged on the side of the brush holder (A).

- Actuation Screw (i): A screw rotates in a bearing on the holder’s top surface and bears against an arm (h′) of the wire frame.

- Function: When the screw (i) is turned, it forces the wire frame (h) inward, compressing the bristles of the brush. This allows the operator to vary the width of the brush to match the exact thickness of the shoe sole, preventing the coloring liquid from staining the marginal edge on the bottom of the sole.

Historical Significance and the Inventor

Clatonia Joaquin Dorticus’s 1895 patent is a key development in the automation and refinement of the shoemaking industry, a major manufacturing sector in the late 19th century.

- Finishing Efficiency: In industrial shoemaking, the final finish of the sole and heel edge (the “edge-setting”) is crucial for the shoe’s visual appeal and value. This task was difficult, time-consuming, and prone to error when done manually with an ordinary brush or sponge. Dorticus’s self-feeding, guided brush offered a fast, consistent, and error-proof mechanical method.

- Solving the Staining Problem: The integration of the guide plate (f) and the adjustable width mechanism (h) directly addressed the major quality control issues of the trade: staining the upper leather (vamp) or the bottom tread. By preventing these defects, the device increased the quality of the finished product while reducing waste.

- The Inventor (Clatonia Joaquin Dorticus): Dorticus was an African-American inventor who held several patents related to footwear and, notably, photography (including a developing apparatus). His work demonstrates an acute ability to apply mechanical solutions to problems requiring high precision and finesse in industrial and domestic settings.

Relation to Current Items

Dorticus’s device contains principles fundamental to modern liquid application and finishing tools:

- Metering Applicators: The use of an adjustable screw to regulate fluid flow (the valve mechanism) is the functional ancestor of all modern metering or controlled-release liquid applicators, from industrial glue guns and caulking guns to sophisticated automated dispensing nozzles in assembly lines.

- Adjustable Brush/Tool Width: The mechanism for compressing the bristles to adjust the working width is a principle used today in many adjustable tools, from variable-width paint rollers to specialized adhesive spreaders, allowing a single tool to be quickly tuned for precise width control.

- Precision Guides: The guide plate (f) that rides in the joint between materials is the concept behind many modern painting and finishing tools, such as specialized edge rollers and trim guides , which use physical barriers to ensure clean, straight lines between two surfaces.