Damper-Regulator (Hugh M. Browne, No. 886,078)

The patent by Hugh M. Browne of Cheyney, Pennsylvania, describes a Damper-Regulator (Patent No. 886,078, 1908). The invention provides reliable means for positively moving and regulating the furnace dampers (draft controls) and for controlling them from a distance, such as a parlor or room above the basement.

Inventor Background: Hugh M. Browne

Hugh M. Browne (1851–1923) was an African-American scientist, educator, and inventor. He served as the principal of the Cheyney Training School for Teachers (now Cheyney University of Pennsylvania). His work in science and education informed his inventions, which focused on applying physics and engineering principles to create practical, efficient solutions for domestic and industrial systems. This patent is a notable application of hydraulic power to residential utility.

Invention and Mechanism (Simplified)

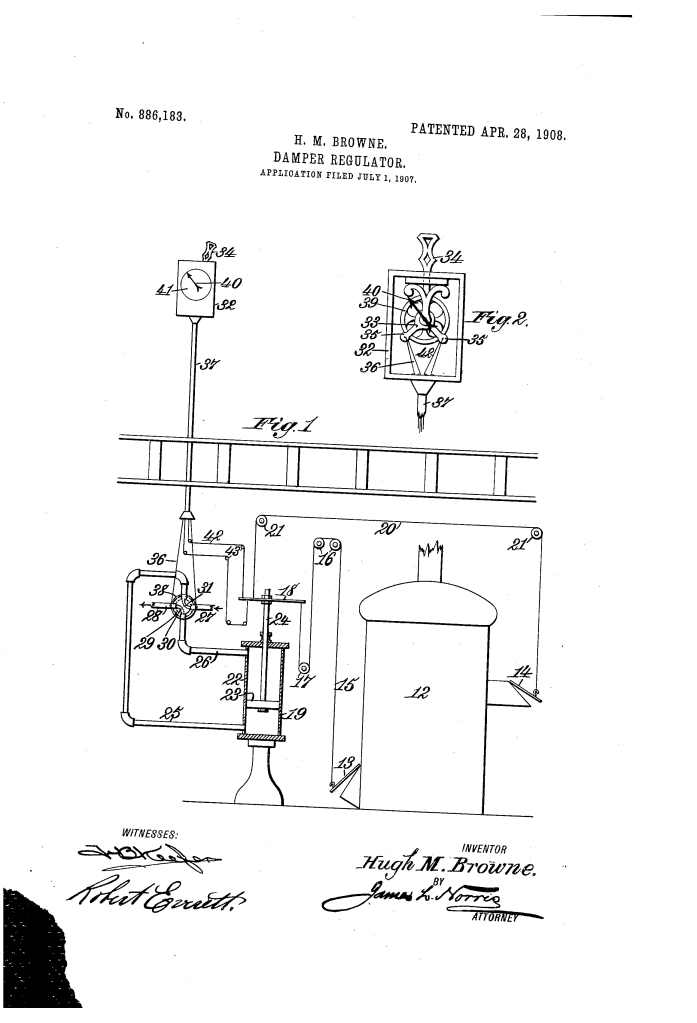

The apparatus is a remote-controlled system that uses water pressure (hydraulic motor) to move the furnace dampers, with a separate indicator confirming the actual damper position.

1. Hydraulic Motor and Damper Control (Key Innovation)

- Regulating Device (19): Preferably an hydraulic motor (a piston 23 inside a cylinder 22).

- Remote Valve (29): A four-way controlling valve (29) is placed at the motor/furnace. Service pipes (25, 26) connect the cylinder ends to a water supply pipe (27) (e.g., house water supply) and an exhaust pipe (28).

- Damper Linkage: A cord or wire (15, 20) connects the motor’s piston rod (18) to the front damper (13) (which controls air intake) and the back damper (14) (which controls flue exhaust).

- Function: Turning the four-way valve (29) directs pressure to one side of the piston (23), causing it to move. This pull/push action simultaneously opens one damper and closes the other, providing precise draft control.

2. Remote Operation

- Control Casing (32): A casing containing the control handle (34) is placed in a conveniently accessible room (e.g., a parlor).

- Handle Linkage: A wire or cord (36) connects the handle (34) to a pulley (38) on the stem of the four-way valve (29).

- Function: Moving the handle (34) in the room causes a corresponding movement of the valve (29) in the basement, remotely shifting the dampers.

3. Independent Position Indicator

- Indicator Pulley (39) and Pointer (40): A separate pulley (39) with a pointer (40) and dial (41) is located in the control casing (32).

- Independent Connection: A cord or wire (42) connects this indicator pulley directly to the motor’s movable member (18) (the piston rod).

- Function: This indicator mechanism is entirely independent of the control handle (34). It shows the actual position of the damper as confirmed by the motor’s movement. If the handle is moved but the motor fails to respond, the operator is instantly notified by the pointer’s failure to move.

Concepts Influenced by This Invention

Browne’s damper regulator influenced subsequent building control systems by pioneering remote hydraulic actuation and fail-safe position feedback.

- Remote Fluid-Powered Actuation: The core concept of using hydraulic pressure (water supply) to power a remote-controlled mechanical actuator (motor 19) for utility control (dampers) influenced the design of early automated building management systems, particularly those using low-cost, readily available water pressure.

- Independent Position Feedback (Indicator): The crucial idea of having a separate, independent mechanical linkage (cord 42) run back from the actuator to the remote control station to confirm the actual position of the regulated part (the damper) influenced the design of modern control systems that require:

- Fail-Safe Monitoring: Ensuring the control input (handle) matches the system output (damper).

- Modulated Fluid Control (Four-Way Valve): The use of a four-way valve (29) to seamlessly direct pressure and exhaust to both sides of a piston influenced the design of pneumatic and hydraulic cylinders for bidirectional control (push/pull).

- Regulated Motion Control: The ability to lock the piston at any point in its travel by positioning the valve (one-eighth turn) to cut off communication influenced the design of positioning systems that require temporary, rigid locking mechanisms.