Curtain-Rod-Support (William S. Grant, No. 565,075)

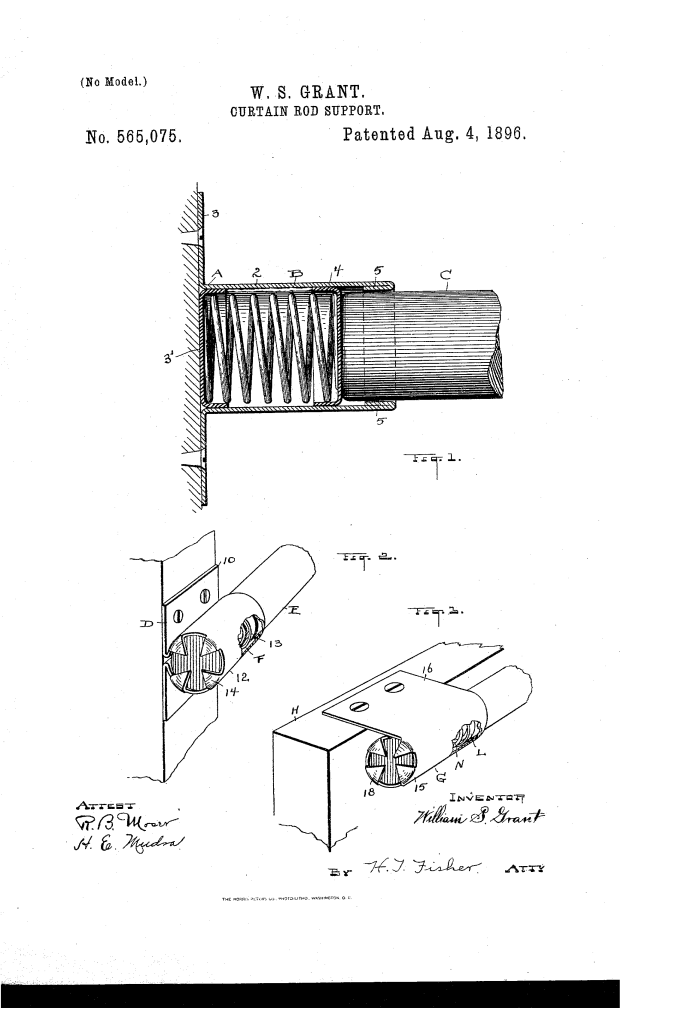

The patent by William S. Grant of Cleveland, Ohio, describes improvements in a Curtain-Rod Support (Patent No. 565,075, 1896). The support is designed for curtains that cover the lower sash or part of a window and need to be frequently changed for washing. The object is to provide a support that is permanently installed but allows the curtain rod to be quickly inserted and removed using a simple, spring-tensioned mechanism.

Invention and Mechanism

The support is a spring-loaded bracket that uses compression to hold the curtain rod securely in place.

- The Support Bracket:

- Socket Portion (2): A tubular or cylindrical socket made from sheet metal.

- Flange (3): A flat flange at the base of the socket, used to fasten the bracket permanently to the window-casing or sash.

- Modularity: Several forms are shown, including one (Fig. 3) designed to mount on the top of the bottom sash (H), allowing the curtain to rise and lower with the sash.

- Spring Retention System (Key Innovation):

- Spiral Spring (B): A fairly stiff spiral spring is permanently confined within the socket (2).

- Bearing Caps (3′ and 4): The spring is housed between two caps or stops.

- Cap (): A fixed inner cap (or the base of the socket) that forms a bearing for the spring.

- Cap (4): A sliding outer cap that moves within the socket and forms the outer bearing for the spring.

- Confinement: The caps and spring are confined by the socket’s construction, such as an inwardly-bent extremity (5) or bent spurs/prongs (14).

- Operation (Quick-Change):

- Insertion: The end of the curtain rod (C) is simply pushed into the socket, pressing against the sliding cap (4) and compressing the spring (B). The tension of the spring is sufficient to hold the rod securely in place.

- Removal: The rod is easily removed by pulling it out, making the process quick and simple for frequent curtain changes.

- Key Design Point: The confinement is designed so that the spring is always held within the bracket, and the bracket remains permanently fixed, solving the problem of constantly re-installing hardware.

Historical Significance and the Inventor

William S. Grant’s 1896 patent addresses a specific, recurring challenge in domestic maintenance—frequent laundering of curtains.

- Domestic Maintenance Efficiency: Curtains, especially those covering the lower sash (known as “sash curtains” or “café curtains”), required frequent washing. Grant’s invention streamlined the tedious process of taking down and rehanging these curtains, which often involved fiddling with small hooks, pins, or screws.

- Simplification and Convenience: The invention replaced complex fastening mechanisms with a simple, push-and-hold spring tension system, demonstrating the late 19th-century demand for consumer products that prioritized ease of use and time saving in the home.

- The Inventor (William S. Grant): Grant, residing in Cleveland, Ohio, contributed to the vast market for domestic hardware and convenience items.

Concepts Influenced by This Invention

Grant’s curtain rod support influenced subsequent hardware design by pioneering a minimalist, friction-fit tension system for quick-release components.

- Spring-Tension Mounting and Quick-Release: The core concept of using a confined internal spring (B) to generate the necessary force for secure, friction-fit mounting is foundational to modern:

- Tension Rods: Curtain rods that fit inside a window casing and hold themselves up by outward spring force.

- Snap-In Hardware: Various tool-less assembly hardware, snap-in drawer slides, and cabinet fixtures that rely on internal spring tension or flexible material compression to secure parts quickly.

- Push-To-Lock Functionality: The mechanism where a rod is secured simply by being pushed into a socket against spring pressure is the basis for modern “push-in” connectors and quick-change tooling that prioritizes speed and convenience over screw fasteners.

- Modular, Permanent Installation: The idea of a permanent mounting fixture (flange 3) that accepts a removable functional piece (rod C) influenced the design of modern modular shelving, rail, and hanging systems.