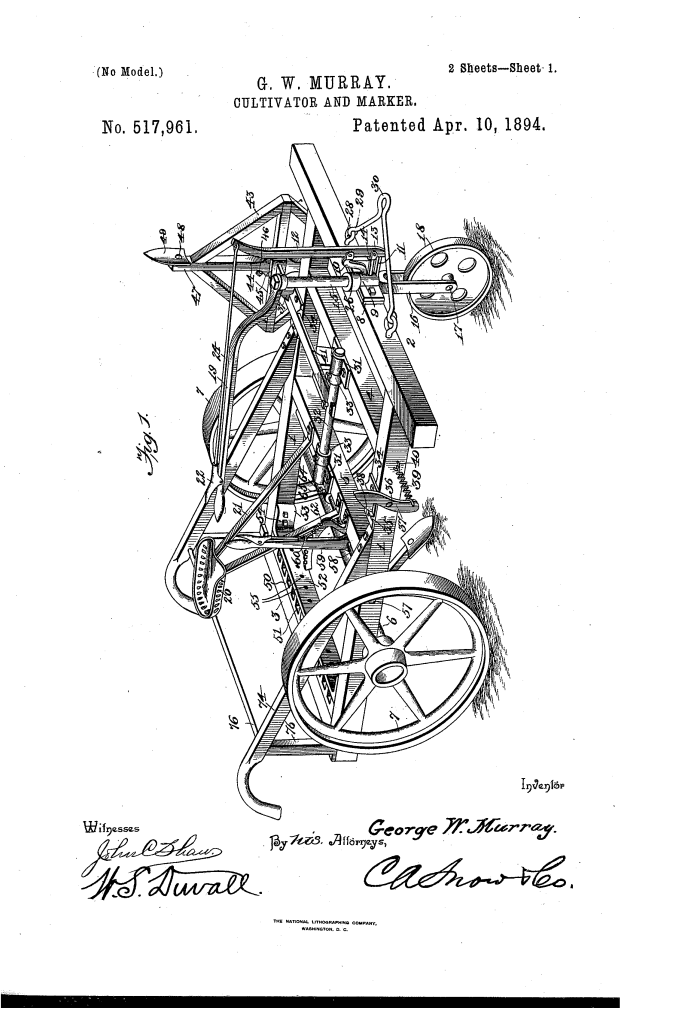

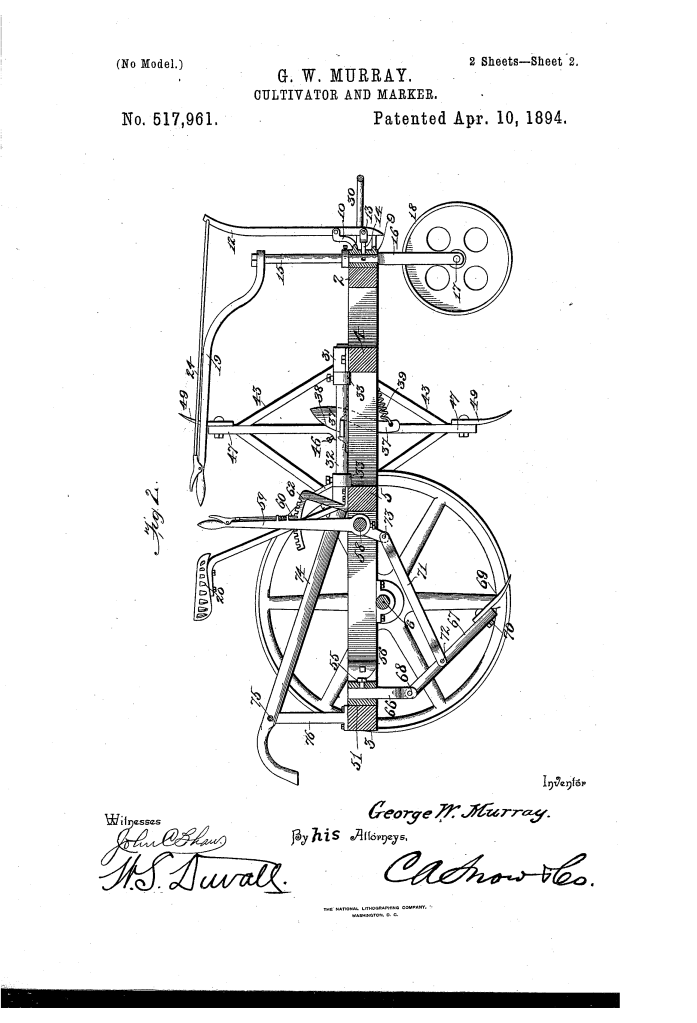

Cultivator and Marker (George W. Murray, No. 517,961)

The patent by George W. Murray of Rembert, South Carolina, describes a combined Cultivator and Marker primarily intended for opening furrows and simultaneously marking the soil for the next furrow. The key objectives were to create a simple, light-draft machine that could be operated by a single person and featured an easily adjustable and reversible marking mechanism.

Invention and Mechanism

The machine is a wheeled, human-operated implement that integrates steering, furrowing, and marking functions.

1. Furrow-Opening Mechanism

- Shovel (69): A furrow-opening shovel of any desired design is secured to an inclined standard (67).

- Vertical Adjustment:

- The inclined standard (67) is pivoted (68) to a vertically adjustable standard (66).

- This system is controlled by a rock-shaft (58), which is rocked by a hand-lever (59) near the operator’s seat (20).

- A link-bar (71) connects the standard (67) to a rigid standard (63) on the rock-shaft (58).

- Function: Operating the lever (59) rocks the shaft (58) to raise or lower the shovel (69) into or out of the ground, and a pawl (60) engaging a toothed segmental standard (62) locks the shovel at any desired depth.

- Lateral Adjustment: The vertical standard (66) is inserted into one of a series of vertical recesses (51) in a cross-bar (50). This allows the main furrowing shovel to be adjusted laterally (side-to-side) across the width of the machine.

2. Marking Mechanism (The Reversible Bar)

- Marking Bar (41): A shaft that extends laterally across the frame and carries the marking devices.

- Marking Shovels (49): Two marking shovels are secured to a diamond-shaped frame (43), which is adjustable along the marking bar (41).

- Function: These shovels score the ground for the succeeding furrow, ensuring the next pass is uniform, straight, and parallel.

- Reversibility and Clamping:

- The marking bar (41) is secured in either of two flanged plates (34) on the frame, where it rests against a vertical shoulder (35).

- Latches (37), pivoted and sprung by coiled springs (39), automatically lock the bar into place once it is seated.

- Function: This arrangement allows the entire marking bar and its shovels to be swung to either side of the machine (reversible) and securely locked, ensuring the marking shovel is always on the proper side regardless of the direction of travel.

3. Steering Mechanism

- Caster-Wheel (18): A wheel swiveled at the front of the frame to guide the machine.

- Guide Handle (19): A curved handle secured to the top of the caster spindle (15), extending rearward for the operator.

- Locking and Release: The spindle (15) has a series of notches (25). A spring-loaded locking bolt (14) engages these notches to hold the caster wheel (and thus the machine) at any desired steering angle.

- Remote Release: A small bell-crank lever (22) on the handle (19) is connected by a wire (24) to the bolt-operating lever (12). This allows the operator to disengage the lock remotely without bending down, facilitating easy steering adjustments.

Historical Significance and the Inventor

This 1894 patent is the second of George W. Murray’s agricultural inventions discussed, further illustrating the ingenuity of this African-American inventor, farmer, and politician in addressing the economic challenges of Southern farming.

- Integrated Efficiency: The core significance lies in the integration of the cultivator and the marker. By combining furrow opening with marking in a single, light-draft pass, Murray reduced the labor required for field preparation, allowing a single operator to perform two distinct, necessary tasks simultaneously and with guaranteed precision between rows.

- Operator Ergonomics and Control: The patent shows advanced consideration for the operator:

- Lever Controls (59, 19): All adjustments (depth, steering, marking position) were within easy reach of the operator, who could ride on the seat (20).

- Remote Steering Lock: The wire-actuated bell-crank lever (22) for the steering lock shows a focus on ergonomics and continuous operation, allowing the farmer to quickly change the steering angle without stopping.

- Versatility: The reversible marking bar and the lateral adjustability of the main shovel made the machine highly versatile, capable of adapting to different row spacings and field conditions.

Relation to Current Items

Murray’s Cultivator and Marker is a precursor to modern precision planting technology:

- Integrated Planning and Planting: The machine’s function of planning the next row while working the current one is fundamental to modern GPS-guided auto-steer systems and precision planters. These systems not only follow previous tracks but also automatically record and plan the precise location of subsequent passes, guaranteeing uniform spacing as Murray intended.

- Quick-Change and Adjustable Implement Mounts: The use of multiple lateral recesses (51) and clamping mechanisms to allow the implement tools (shovels) to be quickly repositioned across the width of the frame is the basis for modern toolbars and quick-hitch systems used on tractors, which allow farming tools to be rapidly configured for different row widths and operations.

- Caster Steering in Implement Design: Caster wheels with locking mechanisms are still commonly used on the front or rear of towed farm implements to provide better stability and to allow the implement to track properly around turns, especially in large-scale modern planters and side-dress units.