Cotton-Picking Apparatus (Albert P. Albert, No. 851,475)

The patent by Albert P. Albert of New Orleans, Louisiana, describes a Cotton-Picking Apparatus (Patent No. 851,475, 1907). The apparatus involves a pneumatic cotton-picking conduit (a tube or pipe) and is designed to provide an efficient, damage-free method of harvesting cotton. The key objectives are to pick only ripe cotton without injuring immature bolls or foliage, and to provide auxiliary means to detach cotton that adheres firmly to the boll.

Inventor Background: Albert P. Albert

Albert P. Albert was an inventor focusing on mechanized agricultural solutions. His invention came during a critical period of intense effort to automate cotton harvesting, which remained one of the most labor-intensive tasks in American agriculture. His pneumatic (suction) design aimed for selectivity and speed, addressing the economic need for efficient harvesting.

Invention and Mechanism (Simplified)

The apparatus is a portable, body-supported suction tube that uses fixed internal spikes to help detach stubborn cotton fibers.

1. Pneumatic Suction and Support

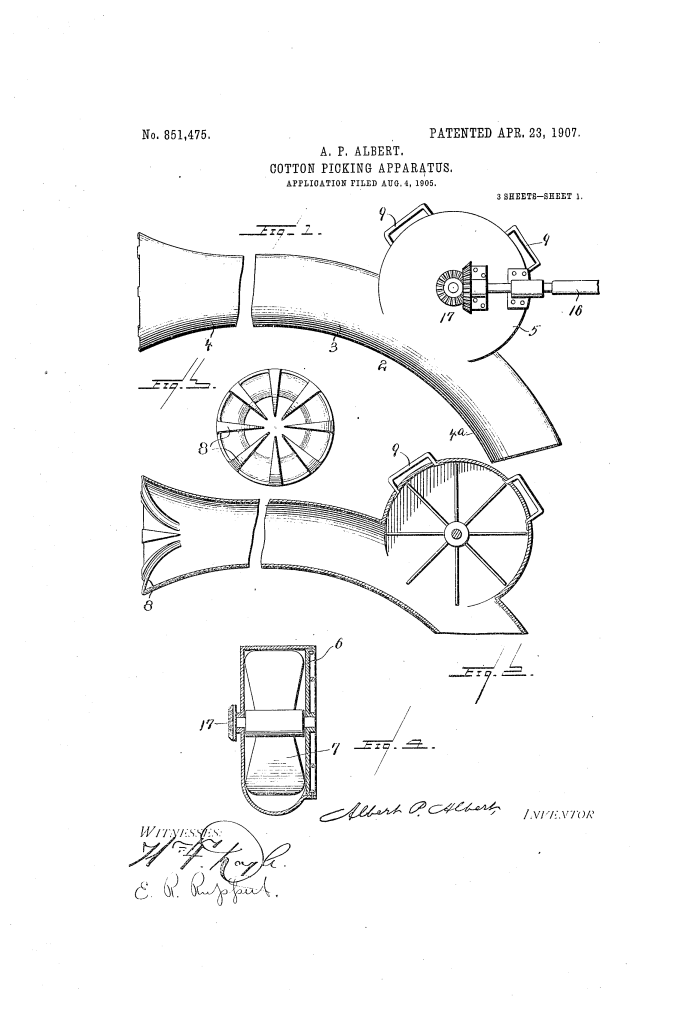

- Conduit (2, 3): A pipe or tube that serves as the cotton-picking channel.

- Integrated Fan (7): A fan (or other air-exhausting device) is directly secured to the conduit (3), intersecting the pipe.

- Function: The fan blades, when rotated by a motor, create suction through the conduit, drawing cotton from the inlet end to the delivery end.

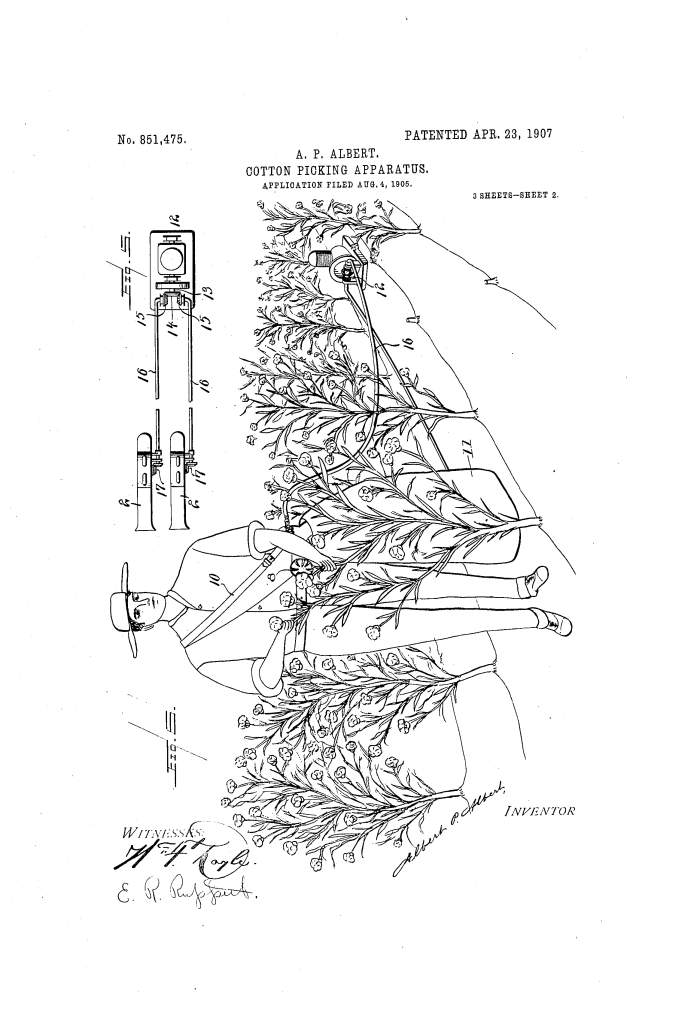

- Body Support: The fan casing (5) has loops (9) through which a strap (10) can be passed, allowing the operator to wear the pipe suspended from their body.

- Result: Both hands of the operator are left free to guide the pipe inlet or draw bolls into proximity.

2. Adherence-Breaking Fingers (Key Innovation)

- Fixed Fingers (8): A plurality of fixed, sharpened or pointed projections (fingers) are rigidly secured within the mouth or inlet end of the conduit. They are somewhat inwardly curved.

- Grid Construction: The fingers are arranged to form a skeleton or grid construction that does not impede the free entry of cotton by suction.

- Function: If cotton adheres too firmly to the boll for suction alone to remove it, the operator moves the conduit to engage the cotton with the sharp ends of the fingers. The fingers grasp the cotton, and when the operator moves the pipe away, the fingers pull or draw the adhering cotton from the boll. The exhaust then carries the cotton away.

3. Motor and Field Operation (Scalability)

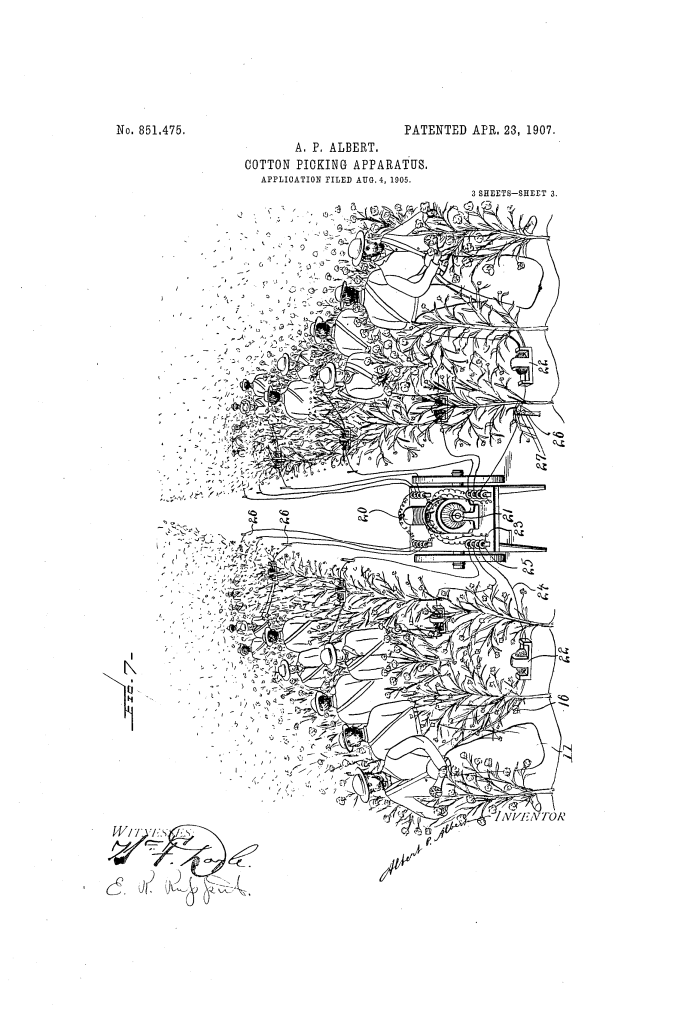

- Flexible Shaft Drive: The fans can be operated by a motor (hydrocarbon or electric) that drives flexible shafts (16). This allows the picker (2) to be freely moved while the motor (12) remains stationary or on a vehicle (23).

- Electric Distribution: In a large field, a dynamo (21) powered by a motor (20) can supply multiple electric motors ($22’$) attached to individual picking devices via guide wires (24) run along furrows.

Concepts Influenced by This Invention

Albert’s apparatus influenced subsequent agricultural and industrial systems by pioneering active, mechanical assistance within pneumatic handling systems.

- Hybrid Pneumatic/Mechanical Gripping: The core concept of using fixed internal projections (fingers 8) to provide mechanical assistance (a grip and pull) when suction alone fails influenced the design of industrial vacuum systems, cotton cleaners, and harvesters. This strategy ensures reliable handling of fibrous materials that often resist simple airflow.

- Ergonomics for Free-Hand Operation: The design’s emphasis on body-supported conveyance (loops 9) to free the operator’s hands for guiding and assisting the process influenced the design of modern portable vacuums, blowers, and specialized agricultural tools that maximize user mobility and task interaction.

- Damage-Free Harvesting: The focus on using the fingers to pull the cotton without drawing in the immature boll or foliage influenced the design philosophy of selective harvesting machinery, prioritizing product quality and plant health.

- Flexible Power Delivery: The provision for driving the fan via flexible shafts (16) or electric motors (22′) influenced the engineering of mobile industrial tools that require continuous power but must be moved dynamically in a field or factory setting.