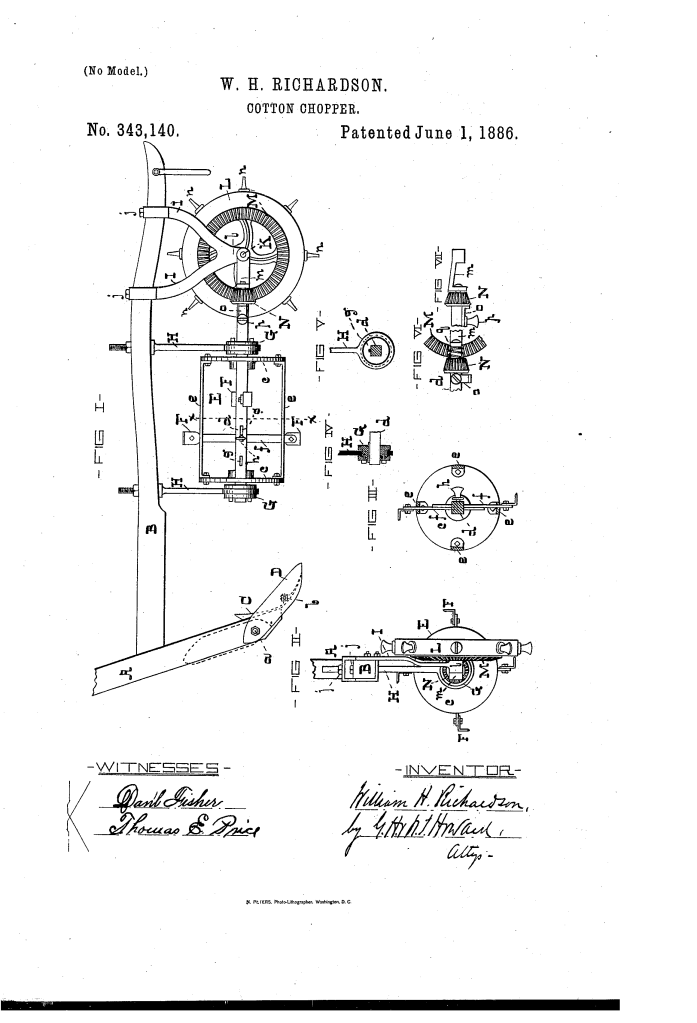

Cotton-Chopper (William H. Richardson, No. 343,140)

The patent by William H. Richardson of Baltimore, Maryland, describes an improvement in Cotton-Choppers (Patent No. 343,140, 1886). The invention is a mechanical attachment designed to be fitted onto a standard plow. Its purpose is to automate the “chopping” or thinning of cotton plants—a process where spaces are cleared in a row of seedlings to leave distinct “hills” for the plants to grow.

Inventor Background: William H. Richardson

William H. Richardson was an African-American inventor whose work focused on agricultural efficiency. In the late 19th century, cotton was the dominant crop in the Southern United States, but thinning the rows was a labor-intensive task usually done by hand with a hoe.3 Richardson’s invention sought to mechanize this process, making it faster and more consistent. His design is notable for its modularity; rather than requiring farmers to buy an entirely new machine, Richardson created an attachment that could be bolted onto existing plows, demonstrating a keen understanding of the economic needs of farmers during the Reconstruction era.

Invention and Mechanism (Simplified)

The device consists of a rotating drum with adjustable hoes that is powered by the forward motion of the plow.

1. The Rotating Hoe Drum (E)

- Skeleton Drum: The heart of the machine is a cylindrical drum (E) made of two heads fastened to a square shaft.

- Adjustable Hoes (F): Metal hoes are bolted to shanks that pass through the shaft and the bars of the drum.

- Function: Because the shanks are held by set-screws, the farmer can slide them in or out to change the depth of the cut. By adding or removing hoes from the various slots, the farmer can also regulate the size of the “hills” left in the cotton row.

2. Ground-Driven Power System (The Drive Wheel)

- Spudded Wheel (L): Attached to a bracket on the plow beam is a large wheel (L) provided with spuds (metal spikes) on its periphery.

- Function: As the plow is pulled forward, the spuds dig into the ground, forcing the wheel (L) to turn.

- Beveled Gearing (M, N): A beveled gear (M) on the inner face of the wheel meshes with a beveled pinion (N) on the square shaft.

- Function: This translates the vertical rotation of the ground wheel into the horizontal rotation of the hoe drum. Richardson included a clutch mechanism (a button and spring) to slide the pinion out of gear, allowing the plow to be moved without the hoes rotating.

3. Modular Attachment (Hangers H and Bracket I)

- Universal Fit: The entire mechanism is supported by hangers (H) and a bracket (I) that slide over the plow beam.

- Function: This makes the hoe mechanism removable and adaptable. Richardson noted that it could be applied to “any plow” simply by boring two holes for the hangers, with wooden liners used to adjust the fit for different beam sizes.

Concepts Influenced by This Invention

Richardson’s cotton-chopper influenced the development of specialized agricultural attachments and precision crop management.

- Ground-Relative Power Take-Off (PTO): The concept of using a spiked drive wheel to power an implement at a speed directly proportional to the vehicle’s forward travel is a precursor to modern agricultural Power Take-Off systems used in tractors today.

- Modularity in Farm Machinery: By creating an “aftermarket” attachment for a standard tool (the plow), Richardson pioneered the logic of modular implementation, allowing farmers to upgrade their existing equipment rather than replacing it.

- Precision Row Thinning: The ability to adjust the “chopping” frequency by changing the number of hoes on a drum influenced the design of modern thinning machines and planters that require precise spacing between plants to maximize crop yield.

- Mechanical Translation (Square Shafting): The use of a square shaft to provide a secure, non-slip mounting point for rotating tools while allowing them to slide for adjustment is a fundamental mechanical principle still used in various industrial drives and axle designs.