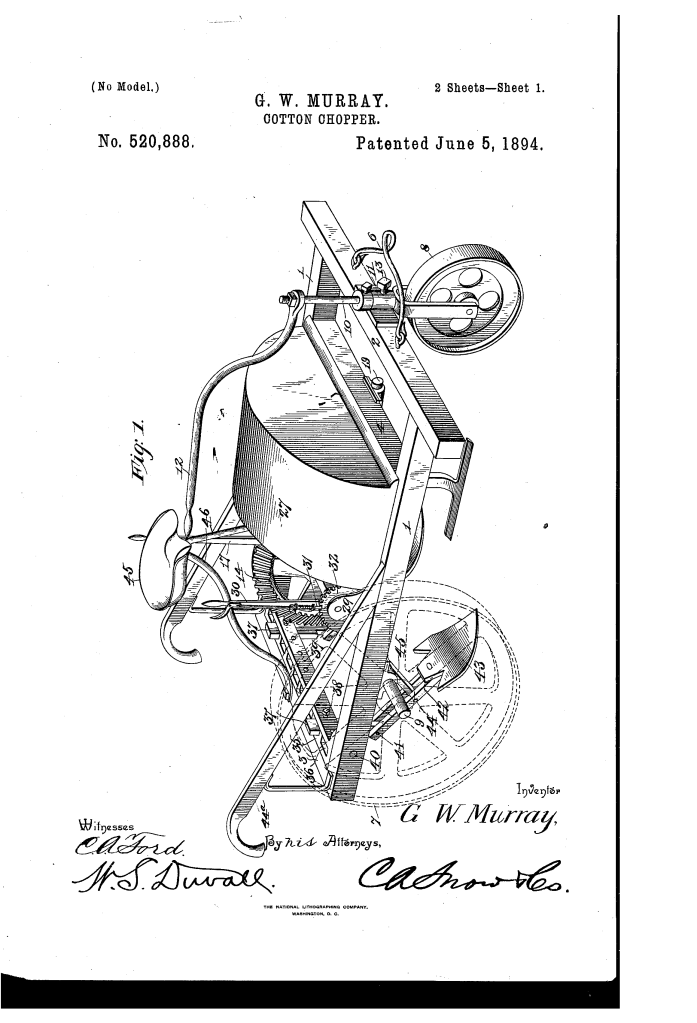

Cotton-Chopper (George W. Murray, No. 520,888)

The patent by George W. Murray of Rembert, South Carolina, describes an improved Cotton-Chopper designed to mechanically thin cotton plants (a process called “chopping”) and simultaneously form the rows. The primary objects are to produce a simple, cheap machine that creates cotton “stands” (groups of remaining plants) of uniform size and spacing.

Invention and Mechanism

The machine is a wheeled, human-operated implement that integrates a rotary chopper with a pair of fixed cultivating plows.

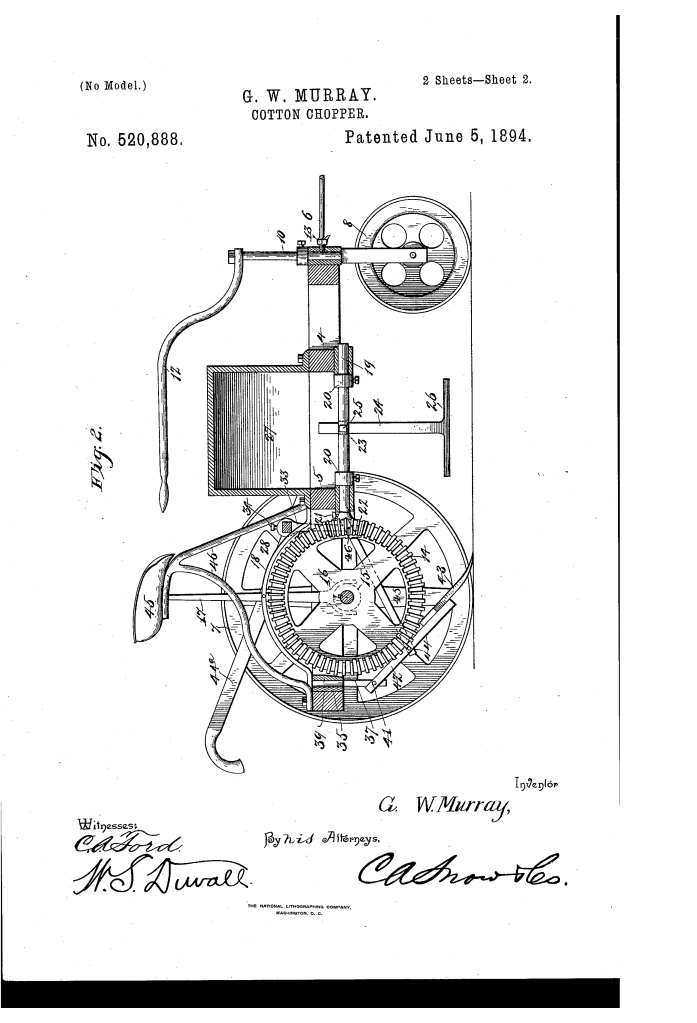

1. Rotary Chopper Mechanism

- Framework: An oblong frame (1-5) supported by rear ground-wheels (7) on an axle (9) and a front caster-wheel (8) for steering.

- Chopping Shaft (19): A short longitudinal shaft journaled in the center of the frame (4, 5).

- Drive Mechanism: The axle (9) carries a master-gear (14) which drives a smaller pinion (22) on the chopping shaft (19).

- Clutch: A hand-lever (17) is used to slide the master-gear (14) along the axle, allowing it to be thrown into or out of operative engagement with the pinion (22) (acting as a clutch).

- Chopping Arm and Hoe (24, 26): A chopping arm (24) is secured to the shaft (19) and carries a hoe (26) at its lower end. The arm is adjustable on the shaft via a binding screw (25).

- Function: Since the pinion (22) is smaller than the master-gear (14), the shaft (19) revolves rapidly. The hoe (26) repeatedly swings down, cutting a swath into the cotton row, removing both weeds and excess cotton plants. The intervals between cuts leave the desired cotton stands.

- Stand Size Adjustment: The pinion (22) is removable. Substituting a larger pinion slows the chopping action relative to the ground speed, resulting in longer intervals between cuts and thus, materially increased stand size.

2. Row Forming and Cultivating Mechanism

- Sweep-Plows (43): A pair of sweep-plows are carried by inclined standards (42).

- Lateral Adjustment: The standards (37) supporting the plows are removably arranged in a series of vertical recesses (36) in a rear cross-bar (35). This allows the distance between the two plows to be adjusted, controlling the width of the stands and the cultivated area.

- Vertical/Depth Adjustment: The plows are connected via link-bars (45) to rock-arms (33) on a transverse rock-shaft (29). A lever (30) operates this rock-shaft.

- Function: This lever allows the operator to raise and lower the plows to control the working depth and lift them out of the ground at the end of a row.

- Combined Function: The sweep-plows follow the rotary chopper, cleaning out furrows at each side of the newly chopped stand, thereby completing the formation of the rows at regular, uniform intervals.

Historical Significance and the Inventor

This is the third of the remarkable 1894 patents by George W. Murray, the African-American inventor and farmer from South Carolina. This invention focuses on the most labor-intensive process in cotton cultivation: thinning.

- The Problem of Thinning (Chopping): After planting, cotton seeds sprout in excess, requiring farmers to thin the plants down to “stands” to optimize growth—a process historically done slowly and tediously with hand hoes. Murray’s chopper provided a mechanical, one-pass solution to this arduous task, offering massive savings in time and labor.

- Uniformity and Precision: By linking the chopping rate directly to the ground speed (via the axle-gear ratio) and providing easy means to adjust the gearing, Murray ensured that the cotton stands were uniform in size and distance, leading to healthier crops and predictable yields. This engineering approach to precision was transformative for small-scale agriculture.

- Holistic Row Management: Murray’s machine didn’t just chop; it also cultivated the sides of the row (sweep-plows), demonstrating an understanding that effective thinning required complete row management in a single, efficient operation.

Relation to Current Items

Murray’s cotton-chopper is a direct conceptual predecessor to modern high-speed agricultural weeding and thinning equipment:

- Mechanical Thinning/Weeding: The rotary hoe/arm system is a forerunner of modern mechanical finger weeders and rotary hoes used in organic and conventional farming to cultivate soil and remove small weeds from row crops, often at high speed.

- Variable Spacing/Population Control: The use of removable pinions (22) to change the stand length relative to the ground is a simple, mechanical form of Variable Rate Technology (VRT). Modern automated thinners use optical sensors and computer-controlled hydraulic blades to precisely select which plants to remove, achieving the same goal of adjustable, predetermined stand populations.

- Integrated Cultivation: The sequential arrangement of the chopper followed by the cultivating plows is a core design feature of modern multi-stage integrated tillage tools that perform several functions (chopping, weeding, tilling, hilling) simultaneously for maximum field efficiency.