Cosmetic and Process of Producing the Same (George Washington Carver, No. 1,522,176)

The patent by George Washington Carver of Tuskegee, Alabama, describes a Cosmetic and Process of Producing the Same (Patent No. 1,522,176, 1925). This invention is a botanical-based skin cream or pomade derived from peanuts. Carver’s primary objective was to create a “vanishing cream” that was naturally nourishing, easily absorbed by the skin, and capable of being tinted to match any desired complexion.

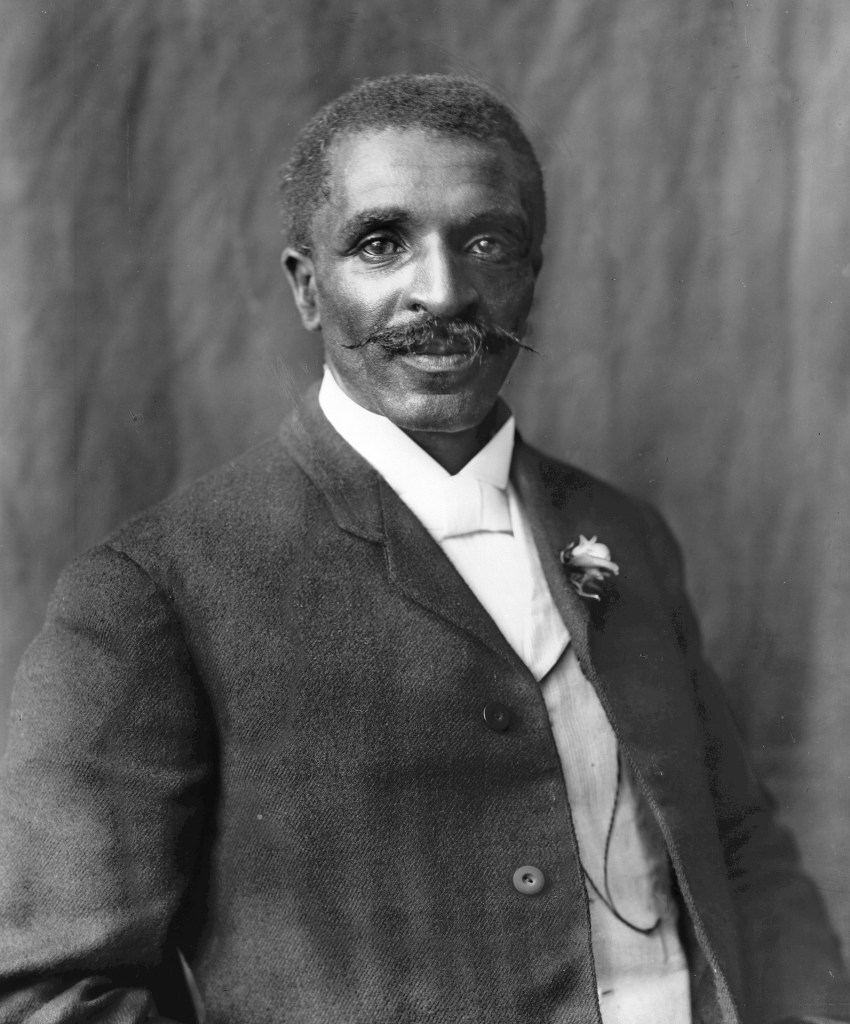

Inventor Background: George Washington Carver

Dr. George Washington Carver was a world-renowned scientist and the Director of Agricultural Research at Tuskegee Institute. Often referred to as “The Peanut Man,” Carver developed over 300 products from peanuts to help Southern farmers diversify their crops away from cotton, which was depleting the soil. This 1925 patent is a rare example of his formal legal filings; while he discovered hundreds of applications, he rarely patented them, believing that his discoveries should be free to the public. This cosmetic patent highlights his mastery of emulsion chemistry—the science of mixing oil and water into a stable cream.

The Manufacturing Process

Carver’s process is a methodical conversion of plant protein and fats into a stable, shelf-ready cosmetic.

1. Maceration and Dilution

- Grinding: Raw, boiled, or blanched peanuts are ground to the fineness of peanut butter. Carver notes that for a “granular” pomade (similar to a modern exfoliating scrub), the grinding is limited.

- Hydration: One ounce of the ground nuts is mixed with 100 c.c. of pure water. This creates a “peanut milk” base rich in proteins and natural fats.

2. Evaporation and Emulsification

- Straining: The mixture is filtered through cheesecloth to remove large solids.

- Reduction: The liquid is heated on a stove or water bath (bain-marie). Carver instructs to evaporate the water until “the oil becomes plainly visible on the surface.” * Oil Enrichment: For a richer cream, 2 c.c. of pure peanut oil is added back into the mass and stirred until it reaches the consistency of thick cream.

3. Compounding the “Vanishing” Effect

- The Powder Base: To give the cream its “vanishing” quality and matte finish, Carver adds approximately six grams of clay-based powders (kaolin, kaolinite, or China clay).

- Tinting: By selecting different toilet powders, Carver explains that the cream can be customized for any skin tone—from “dark brunette shades through the pinks, lavenders, to pure white.”

Chemical Stability and Preservatives

Because natural peanut products are organic and prone to spoilage (rancidity), Carver included a sophisticated preservation system:

| Ingredient | Modern Function | Carver’s Purpose |

| Salicylic Acid | Beta Hydroxy Acid (BHA). | Acts as a preservative and provides a mild chemical exfoliant for the skin. |

| Benzoin | Natural Resin/Antiseptic. | Prevents bacterial growth and adds a slight vanilla-like fragrance. |

| Peanut Oil | Emollient. | Provides Vitamin E and fatty acids to moisturize the skin without being overly greasy. |

| Kaolin Clay | Absorbent. | Absorbs excess skin oils and provides the “vanishing” texture. |

Engineering and Scientific Significance

Carver’s cosmetic was a precursor to the “clean beauty” movement, utilizing plant-based ingredients over the heavy mineral oils and lead-based pigments common in early 20th-century makeup.

- Sustainable Chemistry: He utilized every part of the peanut’s nutritional profile (the fats for moisture, the proteins for structure, and the water-soluble extracts for the base).

- Inclusive Design: One of the most significant aspects of the patent is Carver’s explicit mention of creating shades for “dark brunette” complexions. At a time when the cosmetic industry largely ignored the needs of people of color, Carver used his scientific expertise to create a versatile product for a diverse range of users.

- Homogenization: The final step of the process involves “macerating until absolutely smooth.” This ensured that the clay particles and peanut fats were perfectly suspended, preventing the cream from separating in its glass or porcelain container.