Corn-Silker (Robert P. Scott, No. 524,223)

The patent by Robert P. Scott of Cadiz, Ohio, describes a machine designed for the automated industrial process of removing the silky fiber from green corn after it has been cut from the cob. The primary challenge solved is removing the silk from the corn, which is a “thick, pasty mass,” without simultaneously removing the valuable corn or clogging the machine.

Invention and Mechanism

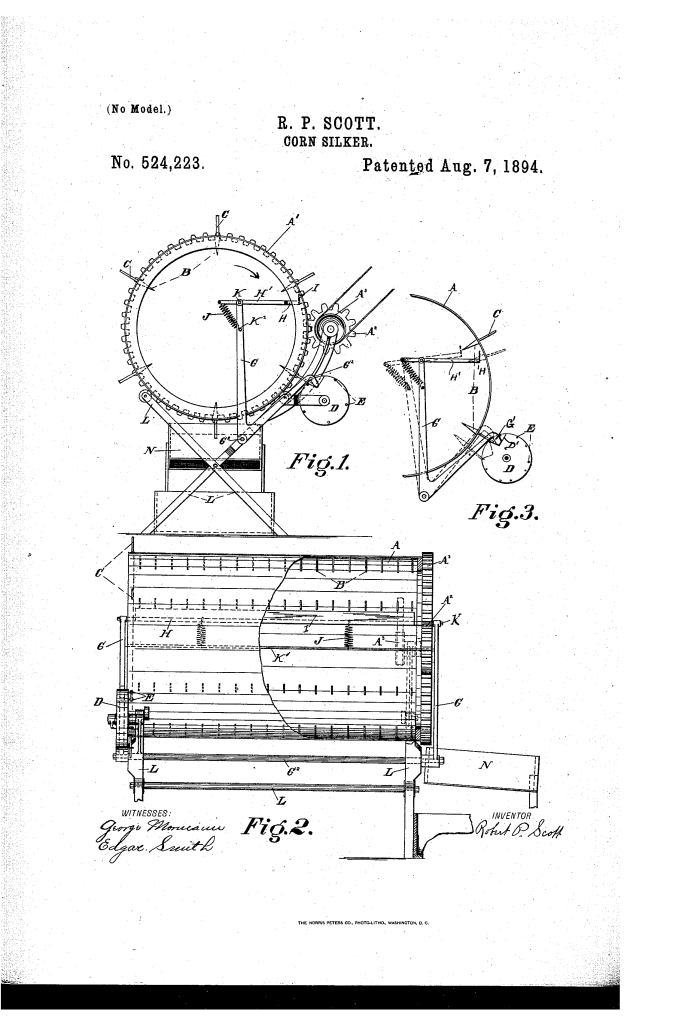

The machine uses a rotating cylinder with specially designed teeth to capture the silk, and a periodic mechanical scraper to clean the teeth.

1. Silking and Gathering

- Rotary Cylinder (A): An open-ended, horizontal or inclined cylinder mounted to rotate on travelers.

- Gathering Teeth (B): Multiple rows of teeth distributed around the inner surface of the cylinder. They are preferably made of thin, wedge-shaped plates or cylindrical pins. The plane of the teeth is at right angles to the cylinder’s axis.

- Function: The cut green corn and intermixed silk are fed into the bottom of the rotating cylinder. The teeth pass transversely through the corn mass and are designed to specifically gather the sticky silk while minimizing the adherence of the pasty corn.

- Separation: As the cylinder rotates, the silk-laden teeth carry the silk to the upper side of the cylinder. The cleaned cut corn, being heavier and non-adherent, passes along the bottom to the open discharge end.

- Sieve (N): A sieve is provided at the discharge end with a shaking motion to remove any remaining particles of husk and cob.

2. Automatic Scraping and Cleaning

- Scraper (I): A scraper, preferably made of a strip of rubber, is located on the upper side of the cylinder. It is fastened to a bar (H) which passes through the cylinder.

- Yielding Mount: The scraper is mounted on a system of bell-crank levers (G) and pivotally mounted levers (H’) at opposite ends of the cylinder. Springs (J) provide the scraper with a yieldable, upward motion.

- Periodic Actuation (Timing): A pin wheel (D), located outside the cylinder, has pins (E) that engage pins (C) on the cylinder’s outer surface.

- The circumference of the pin wheel has a groove (D’). The point (G′) of one of the bell cranks normally rests on the wheel’s circumference.

- Mechanism: When the bell crank’s point (G′) drops into the groove (D′), the bell cranks rock, throwing the scraper (I) down into the path of the gathering teeth (B).

- Differential Gearing for Even Cleaning: The patent notes there are six pins (C) on the cylinder and five pins (E) on the pin wheel. This differential ratio means that for every five revolutions of the cylinder, the pin wheel makes six revolutions, ensuring that a different row of teeth (B) is scraped each time. This distributes the cleaning action evenly, with each set of teeth being scraped once in every five cylinder revolutions.

- Silk Removal: The silk scraped off the teeth adheres to the bar (H), from which it can be removed manually every few hours using a tool shaped like a hoe.

Historical Significance and the Inventor

Robert P. Scott’s 1894 Corn-Silker patent is a significant contribution to the industrialization of food processing, specifically the nascent canned corn industry.

- The Canned Corn Challenge: The rise of commercial canning in the late 19th century demanded efficient methods for preparing food staples. Corn silk is extremely difficult to remove from the viscous mass of cut kernels and, if left in, ruins the texture and appearance of the canned product. Scott’s invention provided a mechanical, high-volume solution to a major production bottleneck that had previously relied on slow, manual methods or inefficient brushing.

- Ingenious Mechanical Timing: The patent is notable for its clever use of differential gearing (6 pins vs. 5 pins) to automate the cleaning cycle and ensure every row of teeth was maintained. This demonstrated a high degree of mechanical sophistication applied to a simple, practical problem.

- The Inventor (Robert P. Scott): Scott, residing in Cadiz, Ohio, contributed to the wave of specialized food machinery inventions emerging from America’s agricultural heartland, driving down production costs and making canned goods a dietary staple.

Relation to Current Items

Scott’s Corn-Silker embodies principles central to modern food and material processing:

- Rotary Drum Separators: The basic design of a rotating drum with internal surfaces to separate materials based on adherence or density is used widely in modern food processing for sorting, washing, and separating , though contemporary versions are often perforated and use washing sprays.

- Self-Cleaning Mechanisms: The inclusion of an automated, timed scraping device to maintain efficiency is a crucial feature of nearly all modern industrial food machinery, from dough mixers to peelers and sorting lines. These machines use sophisticated sensors and actuators for cleaning, but the functional goal remains identical to Scott’s timed scraper.

- Differential Gearing for Maintenance: The technique of using slightly different gear ratios to distribute wear or maintenance cycles across multiple identical components is a standard engineering practice in large industrial machines to maximize uptime and component life.