Combined Furrow-Opener and Stalk-Knocker (George W. Murray, No. 517,960)

The patent by George W. Murray of Sumter, South Carolina, describes an agricultural machine designed to perform two tasks simultaneously in a single pass: open center furrows and knock or break cotton or corn stalks at each side. The stalks are left on the ground to decay and enrich the soil.

Invention and Mechanism

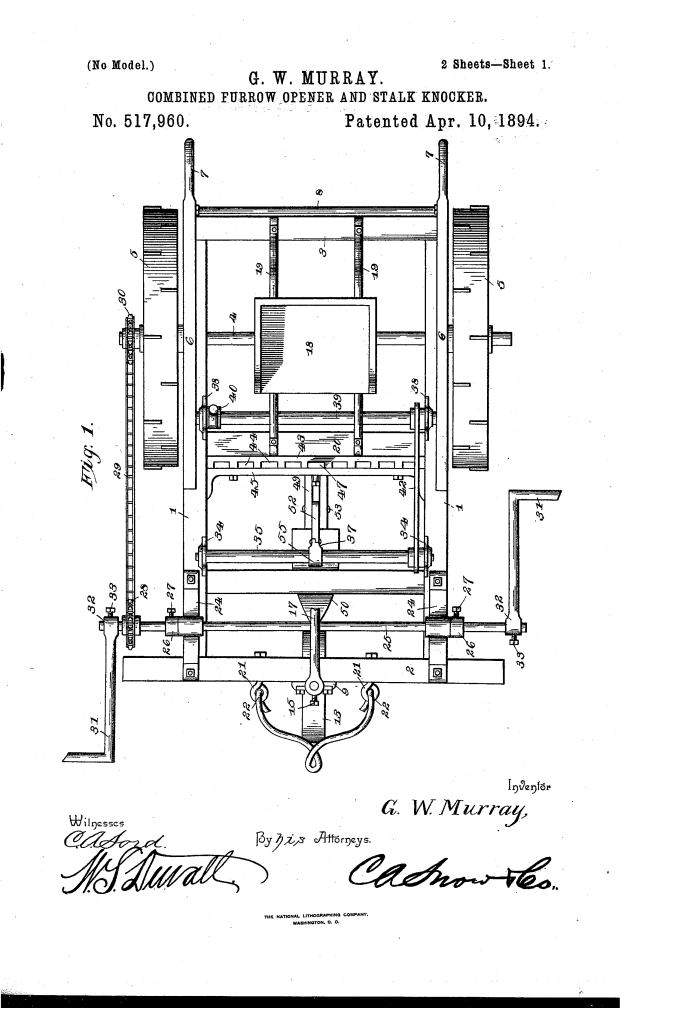

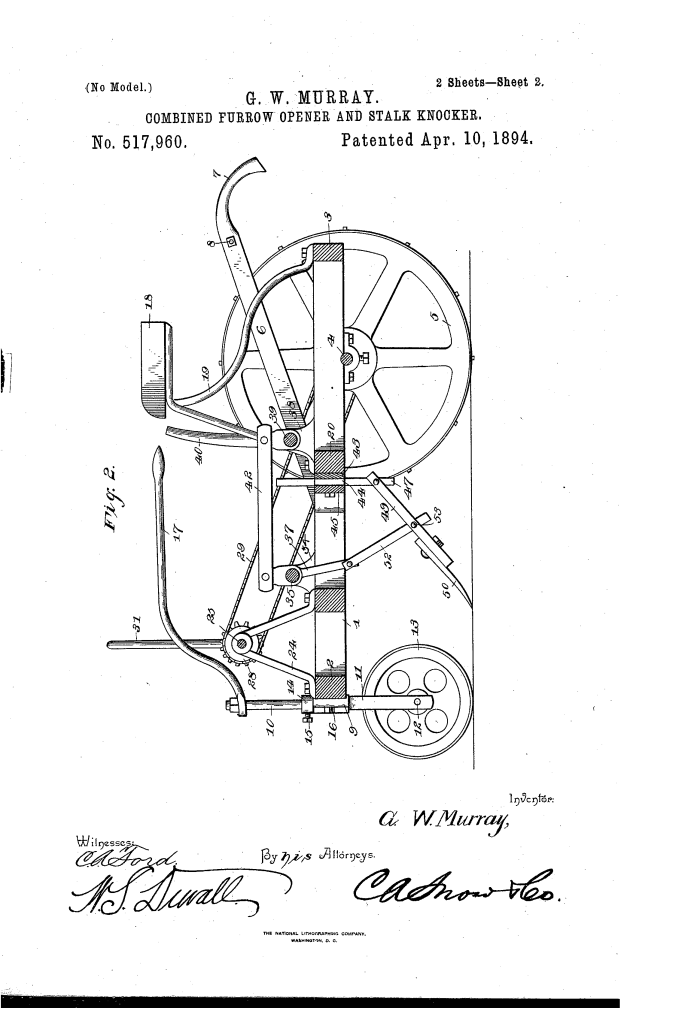

The machine is a wheeled, framed implement that integrates three primary subsystems: the stalk-knocking mechanism, the furrow-opening (plow) mechanism, and the steering system.

1. Stalk-Knocking Mechanism

- Frame and Axle: A rectangular frame (1, 2, 3) mounted on ground-wheels (5) via a transverse axle (4).

- Transverse Shaft (25): Located at the front of the machine, journaled in standards (24). Its position is fixed longitudinally by adjustable bearing-collars (26) and set-screws (27).

- Drive: Motion is transferred from the axle (4) to the shaft (25) via a sprocket-chain (29) connecting a driving-sprocket (30) on the axle to a sprocket-wheel (28) on the shaft.

- Knocking-Arms (31): Crank-shaped arms secured to the ends of the shaft (25). They are oppositely disposed (one up, one down) and are adjustable on the shaft using binding-screws (33).

- Function: As the machine moves, the rotating shaft (25) powers the cranked arms (31) to rapidly strike and break the stalks on the ground to either side of the furrow, preparing the field for the next crop.

2. Furrow-Opening (Plow) Mechanism

- Adjustable Standard (47): A vertical standard held in a mortise (44) in a metal plate (43) at the center of the frame. A clamping-plate (45) secures this standard vertically, allowing the operator to set the initial depth of the plow.

- Inclined Standard (49) and Shovel (50): The inclined standard is slotted and pivoted (48) to the bottom of the vertical standard (47). The furrow-opening shovel (50) is secured to the bottom of this inclined standard.

- Raising/Lowering Control (Rock-Shafts):

- A hand-lever (40) allows the operator to control the plow.

- The lever (40) is connected to a rear rock-shaft (39), which is linked by a connecting-bar (42) to a front rock-shaft (35).

- A rock-arm (37) on the front rock-shaft (35) is connected by a link (52) to the inclined standard (49) just above the shovel (50).

- Function: By pulling or pushing the hand-lever (40), the operator can rock the shafts, using the linkage to raise or lower the plow (shovel 50) entirely from the ground or depress its point to adjust the working depth while the machine is moving.

3. Steering and Control

- Caster Wheel (13): A wheel loosely journaled in a caster fork (11) at the front of the frame.

- Steering Control: The fork has a shank (10) swiveled in a bearing (9). A handle-lever (17) is attached to the shank, allowing the operator, from the seat (18), to rotate the caster wheel (13) to steer the machine.

- Steering Lock: Set-screws (15, 16) threaded into a collar (14) and the bearing-eye (9) allow the caster wheel to be locked in longitudinal alignment or at any preferred angle for steering control.

Historical Significance and the Inventor

The patent by George W. Murray in 1894 is highly significant, particularly given the inventor’s identity and the economic context of the post-Reconstruction South.

- The Inventor (George W. Murray): George Washington Murray (1853–1926) was an African-American inventor, farmer, and politician from South Carolina. He earned the moniker “The Agricultural Moses” for his efforts to improve the economic condition of Black farmers. Murray held at least eight U.S. patents, all related to farm machinery designed to simplify and speed up labor-intensive processes, especially those related to cotton and corn cultivation.

- Economic Empowerment: Murray’s inventions were critical in the post-Reconstruction South where many farmers, particularly Black sharecroppers and small landowners, struggled with poverty and inefficiency. This machine, which combined stalk disposal (a necessary step for soil health and future planting) with furrow opening in one pass, offered a clear path to reducing labor costs and increasing planting efficiency.

- Soil Health: The patent explicitly states the purpose of leaving the broken stalks on the ground is “for the purpose of enriching the same.” This reflects a knowledge of sustainable farming practices (returning organic matter to the soil) and an effort to integrate this vital practice into the efficiency of mechanization.

Relation to Current Items

Murray’s machine is a functional blueprint for modern multi-tasking agricultural equipment:

- Integrated Row Crop Management: The concept of a single machine simultaneously performing residue management (stalk-knocking/chopping) and a tillage/planting preparation task (furrow-opening) is standard for modern strip-till and conservation tillage equipment . These machines often have large rotary choppers at the front followed immediately by fertilizer injectors or planting units.

- Quick-Adjust Mechanisms: The elaborate system of rock-shafts, levers (40), and links (52) to allow the operator to raise or lower the plow instantly is the ancestor of modern hydraulic lift systems used on virtually all tractor-drawn implements. These systems allow operators to precisely control working depth and quickly lift the implement for turning or transport.

- Caster Wheel Steering: The front caster wheel (13) and steering lever (17) are common on smaller, walk-behind or specialized implements for precise row guidance, a design principle that remains effective for small-scale maneuverability.