Combined Excavator and Elevator (Isaiah D. Hughes, No. 687,312)

The patent by Isaiah D. Hughes of Horton, Kansas, describes a new and useful Combined Excavator and Elevator (Patent No. 687,312, 1901) for grading, ditching, and similar purposes. The invention provides a continuous-operation machine that uses ground traction to power both the plows (excavator) and the bucket conveyor (elevator).

Inventor Background: Isaiah D. Hughes

Isaiah D. Hughes was an inventor focused on mechanized agricultural and heavy construction equipment. His invention addresses the need for efficient, large-scale earthmoving that was powered solely by draft animals or by trailing behind a truck, common necessities for grading and ditching on farms or rural infrastructure projects at the turn of the 20th century.

Invention and Mechanism (Simplified)

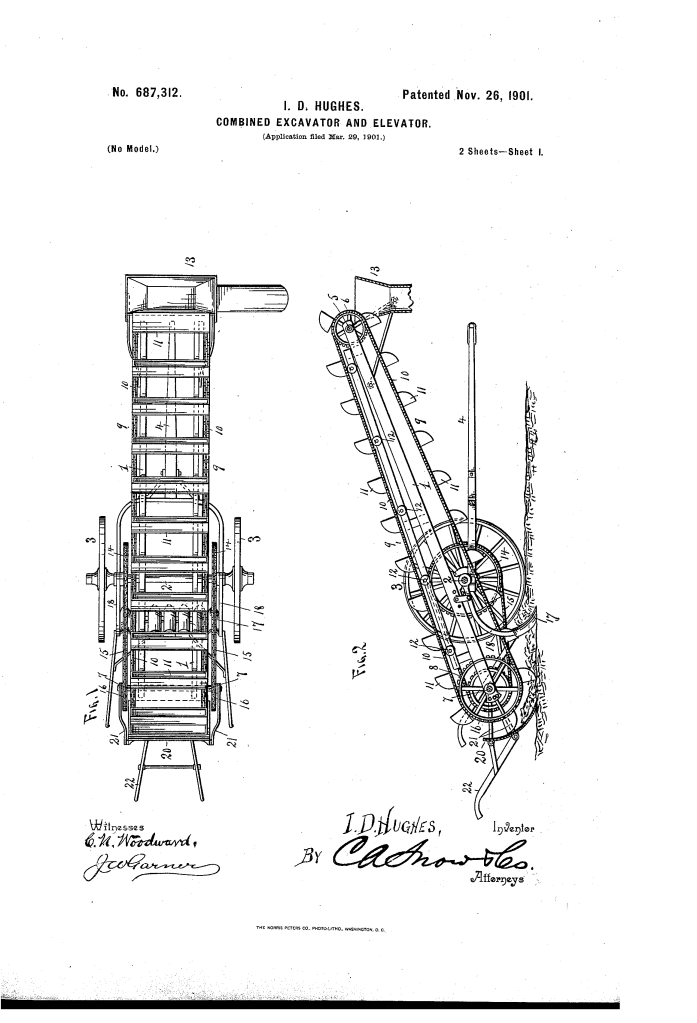

The apparatus is a wheeled, inclined frame that uses ground friction to power a plow assembly and a bucket conveyor to lift and dump the excavated soil.

- Frame and Power:

- Running-Gear and Axle (2): The machine is carried by supporting wheels (3) on an axle (2). The axle is the primary source of power.

- Inclined Frame (1): The frame is pivotally mounted on the axle (2) and is inclined, with the front end higher.

- Power Train: Sprocket-wheels (14) on the axle (2) are connected by chains (15) to sprocket-wheels (16) on the rear shaft (7). Forward movement of the machine communicates power to the elevator.

- Excavation (The Plows):

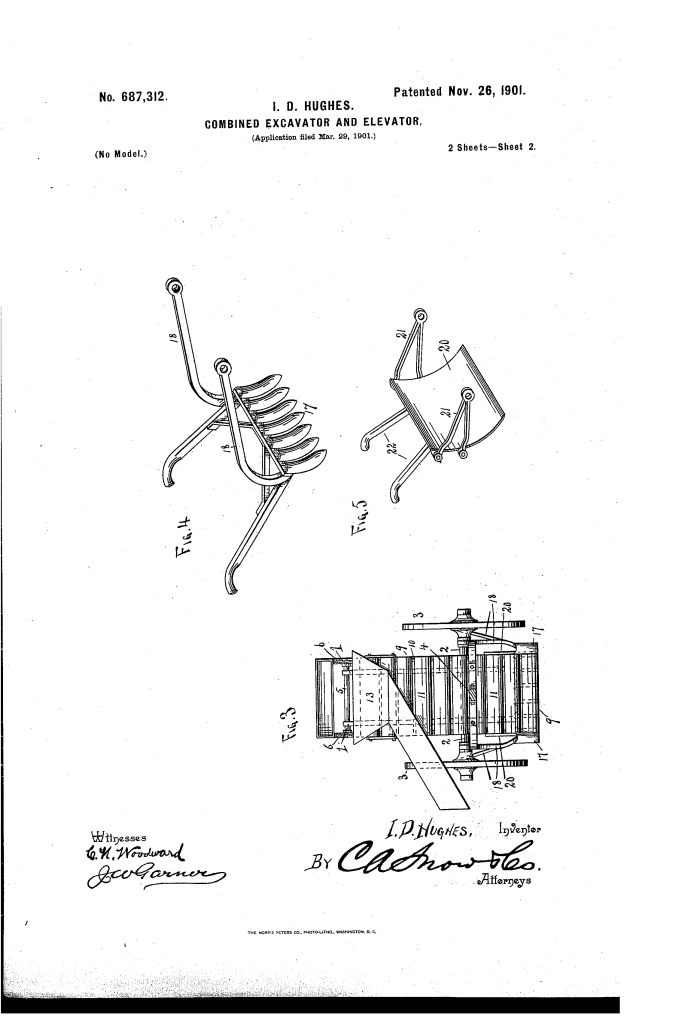

- Plows (17): A series of plows are connected to beams (18). These beams are pivotally attached to the axle (2).

- Function: The pivotal attachment allows the plows to be easily raised or lowered manually using handles (not detailed, but implied) to control the depth of cut in the soil.

- Elevating System:

- Endless Traveling Elevator (9): This consists of sprocket-chains (10) carrying transversely-disposed buckets (11).

- Scraper (20) (Key Innovation): A curved scraper (20) is pivotally attached to the machine behind the plows. The scraper is curved and substantially concentric with the rear shaft (7).

- Function: The plows loosen the earth. The scraper (20) piles the loosened earth up so that the buckets (11) passing around the rear sprocket-wheels (8) become filled by the material thrown up by the scraper. This ensures efficient loading.

- Discharge: The upper lead of the elevator (9) discharges the excavated earth into a spout or trough (13), which conveys the material to the side or to a waiting wagon.

Concepts Influenced by This Invention

Hughes’s machine influenced subsequent designs for continuous excavation and material handling by pioneering integrated, ground-powered lifting and a specialized material scraper.

- Integrated Ground-Powered Conveyance: The core concept of using traction from the running-gear (axle 2) to directly power a continuous bucket elevator (9) influenced the design of early mechanical trenchers, combine harvesters, and continuous-feed material lifters.

- Scraper-Assisted Loading (The Scoop Principle): The specific design of the scraper (20) being concentric with the rear drive shaft (7) to mechanically pile and feed material directly into the elevator buckets influenced the design of subsequent continuous loading systems that use a fixed or moving scraper/auger to ensure the conveyor is fully loaded.

- Pivotal Depth Control: The use of simple pivotal attachment of the plow beams to the axle (2) for manual depth adjustment influenced the design of agricultural equipment that uses the main axle as a reference point for tool depth control.

- Modular Running Gear: The design specified that the running gear could be a tongue for a team or a reach for trailing behind a truck, reinforcing the concept of building modular machinery adaptable to different power sources.