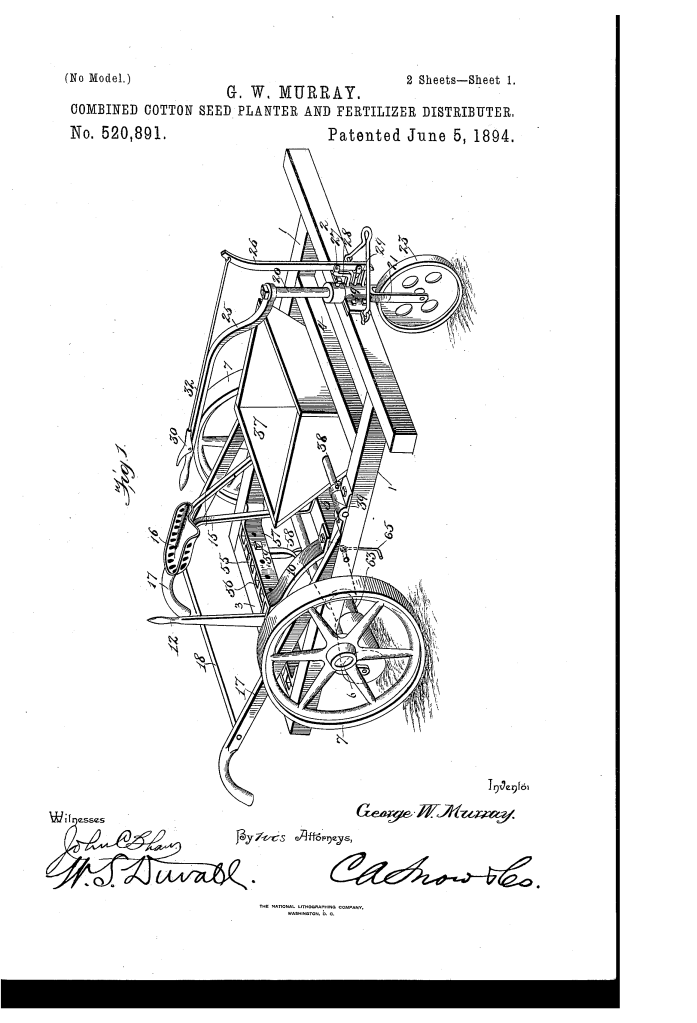

Combined Cotton-Seed Planter and Fertilizer-Distributer (George W. Murray, No. 520,891)

The patent by George W. Murray of Rembert, South Carolina, describes an innovative Combined Cotton-Seed Planter and Fertilizer-Distributer. The machine is designed to perform three functions in one pass: open a furrow, plant/distribute cotton-seed (for growing or fertilizing), and cover/shape the soil. The core objectives were to create a cheap, simple, and durable machine that leaves the soil in condition for future planting.

Invention and Mechanism

The machine is a wheeled, framed agricultural implement that uses specialized tools for sequential soil preparation, planting, and finishing.

1. Furrow Opening and Seed Guidance

- Furrow-Opening Shoe (35): A sharp, V-shaped shoe/point secured to the front meeting point of diagonally converged gage-bars (34). It extends below the bars and has a rounded front edge.

- Function: It opens a precise furrow in the soil for seed and fertilizer deposition.

- Shear-Blades (36): Outwardly flared blades secured to the outer sides of the gage-bars (34).

- Function: These blades follow the shoe (35), potentially clearing and widening the furrow slightly, and generally working the soil.

- Gage-Bars (34): The diagonal bars guide the cotton-seed, which is dropped from the hopper above, ensuring it is deposited accurately into the bottom of the furrow.

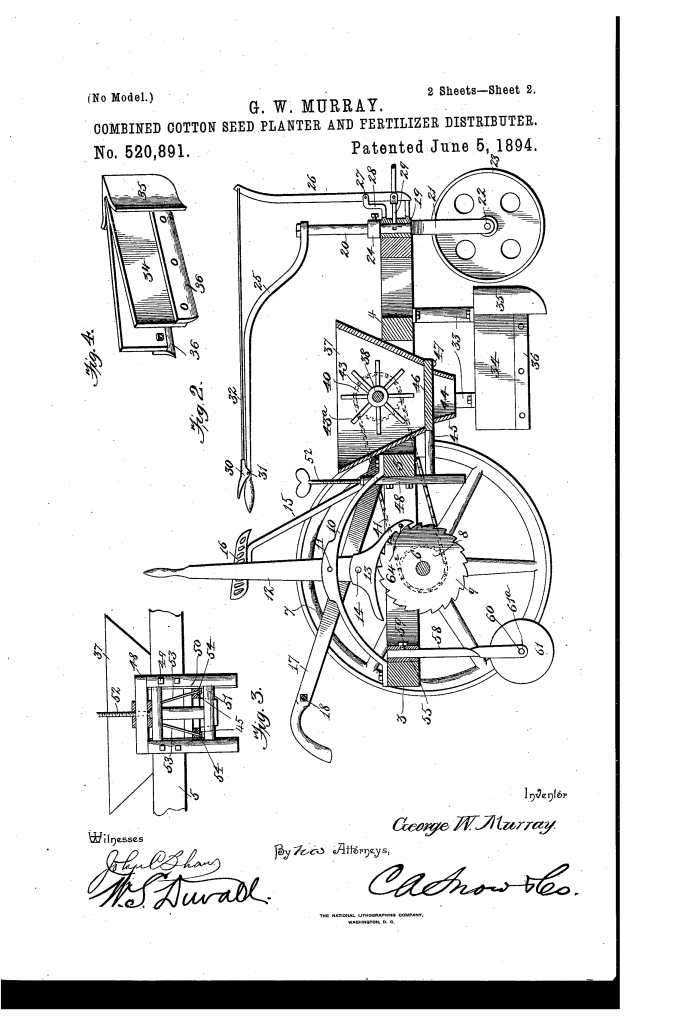

2. Fertilizer/Seed Dropping and Rate Control

- Hopper (37) and Agitator (38): A hopper holds the cotton-seed (which is often used as a cheap fertilizer). A geared agitating-shaft (38), driven by the axle (6), constantly stirs the seed to ensure flow.

- Adjustable Cut-Off (46): The hopper’s discharge is regulated by a cut-off (46) composed of opposite halves carried by a pair of pivoted levers (45).

- Precision Adjustment Mechanism: A complex screw-and-frame system is used to precisely control the cut-off:

- An inverted U-shaped guide-frame (48) holds an H-shaped sliding frame (51) for vertical movement.

- Inclined Guide-Rods (53) are attached to the sliding frame (51) and pass through perforations in the cut-off bars (45).

- An adjusting-screw (52) passes through the guide-frame (48) and engages the sliding frame (51).

- Function: Turning the screw (52) raises or lowers the sliding frame (51). Due to the inclined rods (53), this vertical motion forces the cut-off bars (45) to spread or contract, thereby regulating the amount of cotton-seed (fertilizer) discharged.

3. Covering and Consolidation

- Roller/Blocking-Wheel (61′): A roller mounted at the rear of the machine.

- Contour: The periphery of the roller is concaved inwardly (or gradually reduced toward the center) and has a central annular groove (63).

- Function: This roller operates immediately after seed drop. It beds the soil, forcing it toward the furrow over the cotton, and then the central annular groove (63) creates a clearly defined drill or ridge in the soil, consolidating the seedbed.

- Ratchet System: A ratchet-wheel (9) on the axle and a hand-lever (12) with a pawl (13) allow the operator to reverse the machine temporarily (like a clutch mechanism) to re-cover any missed sections of the row.

Historical Significance and the Inventor

This 1894 patent is the fourth in a series of highly significant agricultural inventions by George W. Murray in a single year, highlighting his vision for a completely mechanized farming system for the Southern economy.

- The Inventor (George W. Murray): As an African-American farmer and politician from South Carolina, Murray directly addressed the technical needs of small-scale farmers in the post-Reconstruction South. By patenting cheap, functional, and highly adjustable machines, he aimed to provide economic self-sufficiency and efficiency through mechanization.

- The Dual Purpose of Cotton-Seed: The patent explicitly notes the machine’s dual utility: planting cotton for growing or dropping it for fertilizing purposes. Cotton-seed was often used as a cheap organic fertilizer. This machine was designed to apply this fertilizer evenly and then prepare the soil (the “drill”) for subsequent planting of cash crops.

- Achieving Precision: The elaborate system for controlling the cut-off (using the screw, sliding frame, and inclined rods) demonstrates an advanced engineering approach to planting rate precision. This mechanism was vital for accurately rationing expensive seeds or fertilizer, maximizing yield and minimizing waste.

Relation to Current Items

Murray’s combined machine integrates mechanical principles that are essential to modern precision agriculture:

- Row-Unit Integration: The sequential arrangement of a furrow opener → metering/dropping mechanism → closing/press wheel is the standard, fundamental design of every modern row-unit on a planter .

- Precision Metering Adjustment: The vertical screw (52) translating into horizontal movement (spreading the bars 45) to control flow is a sophisticated mechanical solution that is the ancestor of modern screw-type micro-adjustments and rate-control valves used in granular fertilizer and chemical applicators.

- Seedbed Consolidation: The concaved roller (61′) that creates a finished drill is the functional precursor to modern spoke closing wheels and rubber press wheels on planters, which are designed to firm the soil over the seed, ensuring optimal soil-to-seed contact for rapid germination.

- Ratchet/Reverse Gear: The ratchet system (9, 12) allowing the machine to be reversed or momentarily disengaged is a fundamental safety and maneuverability feature found in various forms of walk-behind equipment and specialized garden tillers.