Improved Hair-Straightening Comb (Walter H. Sammons, No. 1,343,899)

The patent by Walter H. Sammons of Philadelphia, Pennsylvania, describes an improved Comb (Patent No. 1,343,899, 1920). This invention is a specialized “pressing comb” designed to remove kinks or curls from hair. Sammons’s primary goal was to improve the safety and reliability of the tool, which was typically heated over a stove before use. His design introduced a built-in thermometer for precise temperature control and a multi-layered thermal insulation system to prevent the user’s hands from being burned.

Inventor Background: Walter H. Sammons

Walter H. Sammons was an African American inventor based in Philadelphia during the early 20th century. His 1920 patent addressed a major danger in the beauty industry: “irreparable damage” to hair caused by overheating and frequent burns to the stylist’s hands. While hot combs had been used for decades, Sammons applied advanced thermodynamic engineering to a cosmetic tool. His focus on “experienced hands” versus the average user led him to create a device that made professional results safer for everyone, demonstrating a mastery of heat conductivity and mechanical assembly.

Key Mechanical Components & Functions

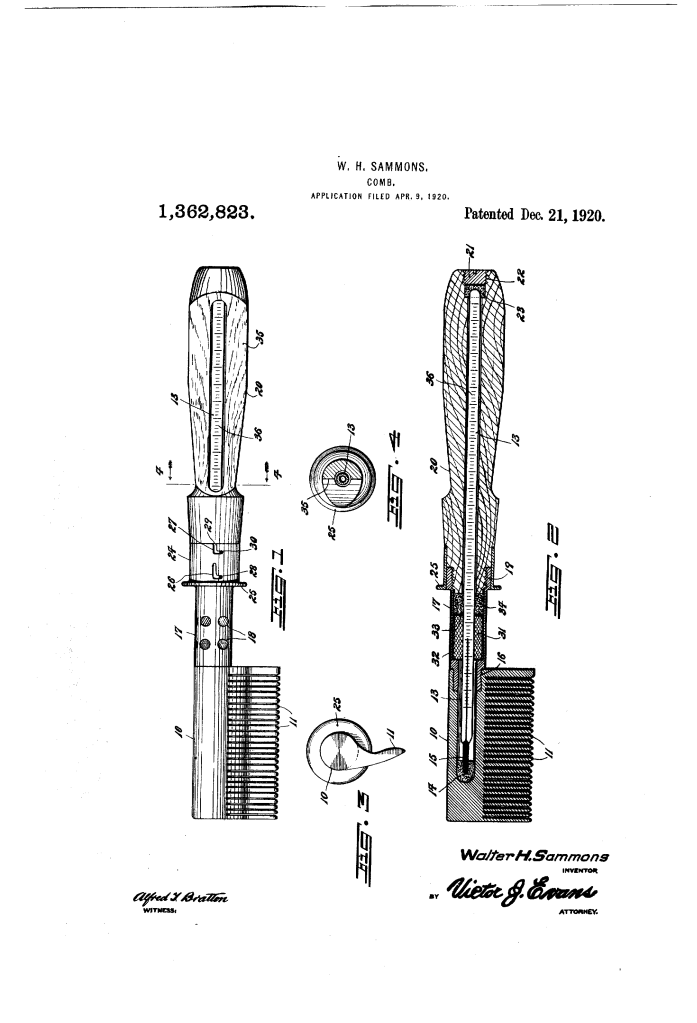

The comb is a complex assembly of metallic, heat-conducting parts and protective, heat-resisting materials.

1. The Comb Head and “Wiper” Teeth (10, 11)

- Cylindrical Head: The comb head (10) is made of metal and is circular in cross-section. It is hollowed out to act as a heat reservoir.

- Wiper Teeth: The teeth (11) project at right angles. They are shaped like “wipers”—smooth and evenly curved.

- Function: This shape allows the comb to smooth the hair out while the heated head (10) presses against the roots, transmitting heat thoroughly to straighten the hair without snagging.

2. The Integrated Thermometer (13, 35, 36) (Key Innovation)

- Axial Placement: A thermometer (13) is housed centrally, extending from the comb head all the way into the handle.

- Sight Opening (35): The handle features a cutaway or slot (35).

- Function: This allows the user to see the degree markings (36) at a glance. By reading the temperature, the user can ensure the comb is hot enough to work but not so hot that it scorches the hair.

3. The Triple-Insulation System (17, 31, 34)

To keep the handle (20) cool, Sammons utilized three distinct engineering methods:

- The Cooling Chamber (31): A tubular extension (17) between the head and handle features holes or apertures (18). This creates an air-cooled chamber that dissipates heat before it reaches the hand.

- Asbestos Filler (34): A non-conducting asbestos filler (34) is packed inside the extension to block heat conduction.

- Gauze Screen (32): A fine gauze tube (32) lines the extension.

- Function: This prevents dirt from entering the cooling chamber while still allowing air to circulate.

4. The Flanged Locking Sleeve (24, 25)

- Safety Flange (25): A metal sleeve (24) connects the handle to the extension and features an outwardly flared flange (25).

- Function: This flange acts as a physical barrier or “guard,” preventing the user’s fingers from accidentally sliding forward onto the scorching metal parts of the comb.

- Bayonet Slots (26, 27): These allow the handle to be easily removed or locked into place with a simple twist and slide.

Improvements Over Existing Hot Combs

| Feature | Standard Hot Combs (c. 1910) | Sammons’s Improved Comb |

| Heat Control | Manual guessing or “singe-tests.” | Integrated thermometer for exact readings. |

| Handle Safety | Metal handles got too hot to hold. | Triple insulation (Air, Asbestos, Hardwood). |

| User Protection | Frequent finger burns. | Safety flange (25) blocks finger contact with hot metal. |

| Hygiene | Dirt and hair oils clogged the mechanism. | Gauze screen (32) keeps the internal chamber clean. |

Significance to Cosmetic Engineering

Walter H. Sammons’s comb influenced the development of calibrated hair-care technology and ergonomic tool design.

- Thermal Precision: By making the thermometer “axial” (running down the center), Sammons ensured the reading reflected the internal heat of the entire tool, a principle used in modern digital flat irons.

- Safety Guards: The protective flange is a classic example of human factors engineering, designing a physical safeguard into a hand tool to prevent common injuries.

- Modular Assembly: The use of bayonet slots and threaded connections made the tool easy to clean and repair, anticipating the interchangeable parts common in modern salon equipment.

- Materials Science: His combination of “wiper” geometry for the teeth and asbestos/hardwood for insulation showed a sophisticated understanding of how to manage heat transfer (conductivity vs. resistance).