Improved Hair-Straightening Comb (Sacramenta G. Tankins, No. 1,339,632)

The patent by Sacramenta G. Tankins of Atlantic City, New Jersey, describes an improved Comb (Patent No. 1,339,632, 1920). This invention is a specialized metallic “pressing comb” used to straighten curly or kinky hair. Tankins’s primary innovation was the integration of a thermometer into the comb’s handle and shank. This allowed users to monitor the heat levels precisely, solving the dangerous problem of “scorching” the hair with an overheated comb or failing to achieve lasting results with one that was too cool.

Inventor Background: Sacramenta G. Tankins

Sacramenta G. Tankins was an African American inventor and businessman. His 1920 patent addressed a critical need in the growing hair-care industry of the early 20th century. While hot combs had been popularized by pioneers like Madam C.J. Walker, they were often heated over open flames or stoves, making the temperature difficult to gauge. Tankins applied principles of thermal instrumentation to a cosmetic tool, creating a safer, more professional instrument that bridged the gap between traditional hairdressing and modern scientific beauty standards.

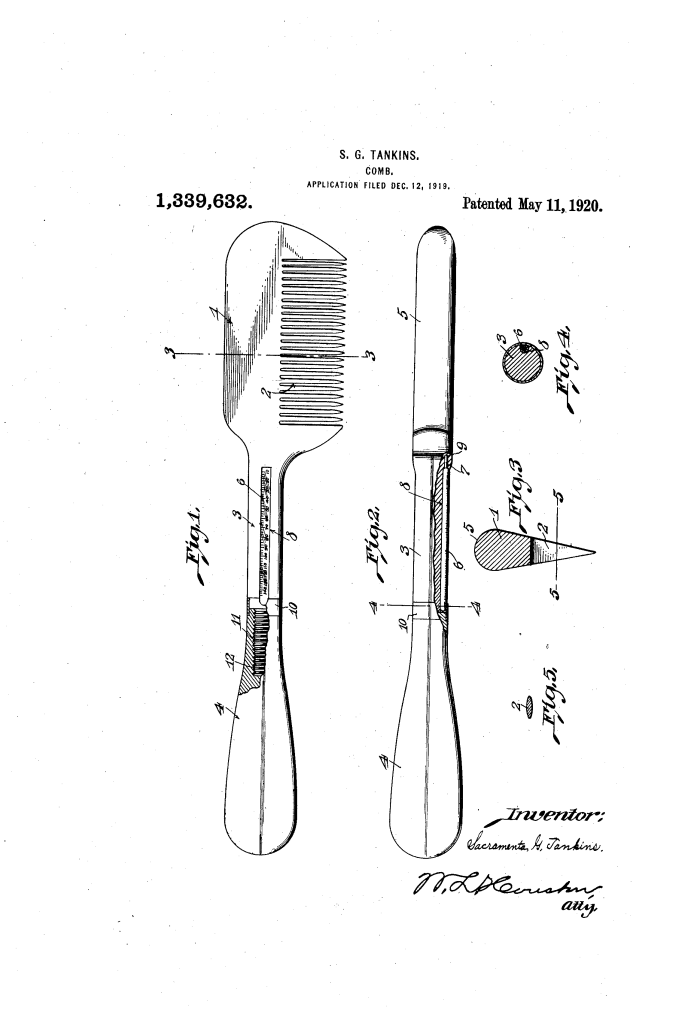

Key Mechanical Components & Functions

The comb is designed for high heat retention and precise thermal measurement.

1. The Heavy Metallic Back (1)

- Heat Reservoir: The back (1) of the comb is made of thick metal, such as iron.

- Thermal Mass: Its thickness is intentional; a larger mass of metal retains heat longer, allowing the stylist to work on more hair before needing to reheat the tool.

- Rounded Surfaces (5): The back is rounded to ensure the tool passes smoothly over the hair, effectively “ironing” it without snagging.

2. Elliptical Teeth (2)

- Cross-Sectional Shape: Unlike standard flat teeth, these teeth (2) are substantially elliptical (oval) in shape.

- Increased Surface Area: This shape presents a larger heated surface area to the hair strand.

- Function: This allows the comb to eliminate curls more effectively in fewer passes, reducing the risk of tearing or breaking the hair fibers.

3. The Integrated Thermometer (6, 7) (Key Innovation)

- Mercury Type: A standard mercury thermometer (6) is embedded in the tool.

- Recessed Placement (8): The shank (3) of the comb features a longitudinal recess (8) where the thermometer is snugly seated.

- Bulb Location (9): The bulb (7) of the thermometer is housed in a specialized socket (9) located directly adjacent to the comb’s back.

- Function: By placing the bulb at the point where the handle meets the heated head, the thermometer provides an accurate reading of the “effective portion” of the instrument, letting the user know exactly when it has reached the ideal temperature for straightening.

4. The Removable Handle and Ferrule (4, 10)

- Non-Conducting Material: The handle (4) is made of wood or another material that does not conduct heat, protecting the user’s hand.

- Protection and Accessibility: A metal ferrule (10) slides over the end of the thermometer.

- Function: This ferrule protects the glass thermometer from breaking during rugged use while still allowing the scale to be clearly visible. It also allows the thermometer to be easily replaced if it should shatter.

Improvements Over Standard Hot Combs

| Feature | Standard Hot Combs (c. 1915) | Tankins’s Improved Comb |

| Safety | Relied on “touch-tests” or guessing; high risk of burns. | Integrated thermometer provides exact temperature readings. |

| Result Quality | Inconsistent heat led to temporary or uneven straightening. | Precise heat control ensures permanent curl elimination. |

| Hair Health | Overheating often resulted in scorched, brittle hair. | Prevents scorching by notifying the user of excessive heat. |

| Durability | Solid-state; if broken, the tool was useless. | Modular design allows for replacement of the thermometer unit. |

Significance to Cosmetic Engineering

Sacramenta G. Tankins’s comb influenced the development of calibrated beauty tools and consumer safety standards.

- The Scientific Beauty Movement: Tankins was one of the first to argue that hair care should be a precise, measurable process. This logic paved the way for modern adjustable-heat flat irons and curling wands.

- Thermal Sensing Integration: The engineering challenge of embedding a fragile glass instrument into a heavy, high-heat metal tool required sophisticated vibration dampening and thermal coupling (via the socket and ferrule).

- Ergonomics and Visibility: By placing the thermometer scale where it could be “readily seen while the instrument is in use,” Tankins prioritized the user interface, ensuring safety didn’t interfere with the speed of work.

- Material Selection: The combination of high-thermal-mass iron with low-conductivity wood and sensitive mercury instruments demonstrated a complex understanding of thermodynamics in a domestic setting.