Coal or Ore Bucket (James A. Joyce, No. 603,143)

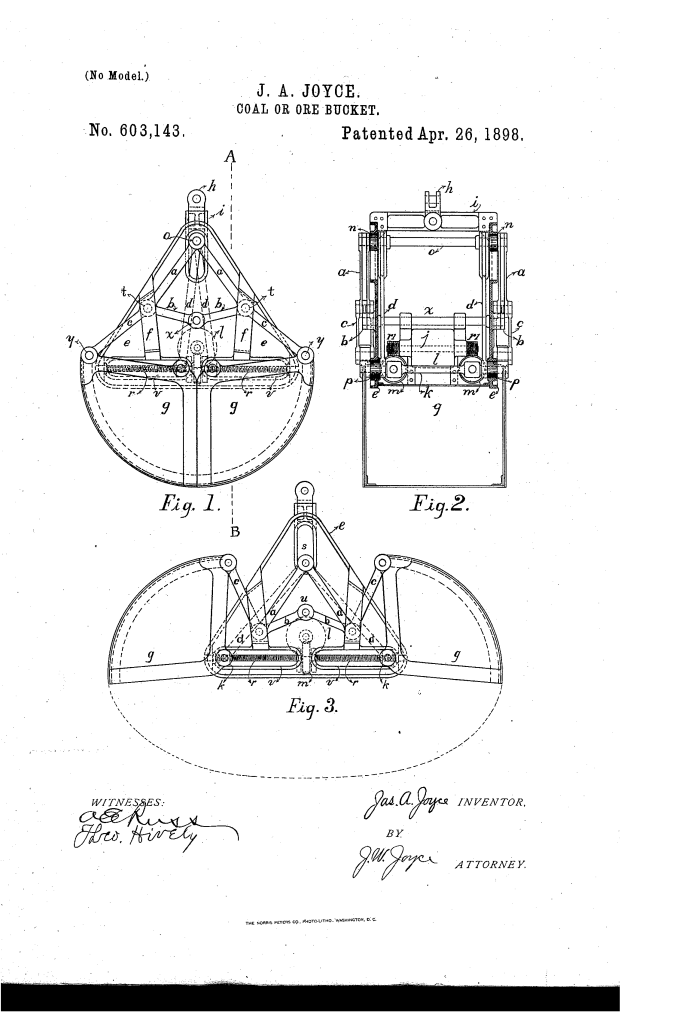

The patent by James A. Joyce of Cleveland, Ohio, describes a new and useful Coal or Ore Bucket (Patent No. 603,143, 1898), commonly known as a clamshell grab bucket. The invention focuses on the mechanism used to close the two halves of the bucket with a powerful, coordinated scraping and cutting motion for efficient loading of bulk materials.

Inventor Background: James A. Joyce

James A. Joyce was an inventor specializing in industrial material handling solutions. His invention came during the late 19th-century boom in mining, rail transport, and heavy industry, where efficient mechanical loading and unloading of bulk commodities (coal, iron ore, gravel) were critical for speed and profit. His design aimed to improve upon earlier grab buckets by providing a more powerful and precise closing action.

Invention and Mechanism

The bucket is a power-operated, link-driven mechanism that converts rotational motor power into synchronized linear and vertical motion for the digging action.

1. Bucket Structure and Drive

- Bucket Halves ($g, g’$): The two halves of the bucket, each with sides and a curved bottom.

- Frame (e): The fixed support frame from which the bucket is hoisted (h).

- Motive Power (l): An electric motor or other motive power drives a horizontal shaft (l) with worms ($r$) at each end.

- Screw Drive: The worms ($r$) engage worm-wheels ($m$), which are fastened to screw-shafts ($r’$ ).

2. Synchronized Closing Mechanism (Key Innovation)

The closing action is controlled by three sets of movable beams linked to the bucket halves and driven by the screws:

- Lower Cross-Bars ($k$): Transverse bars that pass through the bucket halves ($g, g’$) and are movable in horizontal guides in the frame. These bars have threaded openings engaged by the screw-shafts ($r’$).

- Function: As the screws ($r’$) revolve, the bars ($k$) are forced horizontally toward the center, pulling the digging edges of the bucket halves together.

- Upper Cross-Bar ($o$): A transverse bar movable vertically in guides.

- Function: This bar is moved vertically upward from the center by the action of the screws and links.

- System of Links ($a, c, d$): A network of links connects the movable beams ($k$ and $o$) to the bucket sections.

- Function: The coordinated horizontal movement of bars ($k$) and the vertical movement of bar ($o$) forces the bucket halves to close with a scraping and cutting motion whose path of travel “very closely resembles that of an ellipse”

. This complex, powerful motion ensures the bucket digs into and scrapes up the material efficiently.

3. Operation

To close the bucket, the motor is activated, turning the screws ($r’$), which drives the synchronized link system to perform the cutting and scraping scoop motion. The reverse motion of the motor opens the bucket for discharge.

Concepts Influenced by This Invention

Joyce’s grab bucket influenced subsequent heavy material handling design by pioneering the use of complex kinematic linkages for synchronized, high-force scooping.

- Kinematic Synthesis for Digging: The core concept of using a multi-bar linkage (a, c, d) actuated by screw drives ($r’$) to create a specific, complex, elliptical motion for the digging edge influenced the design of modern clamshell excavators, hydraulic shovels, and bulk material grabs . These systems use cylinders and linkages to synthesize complex digging paths that maximize material capture.

- Screw-Drive Actuation in Heavy Machinery: The use of high-torque worm and screw drives ($r, m, r’$) to provide the necessary slow, powerful force for closing a heavy industrial bucket influenced the design of industrial actuators and tensioning devices where smooth, high-force linear motion is required.

- Coordinated Dual-Action: The mechanism that synchronizes the inward/horizontal closure (via bars k) with the vertical lift (via bar o) is a crucial principle for ensuring the bucket digs efficiently before lifting, which is fundamental to modern excavator design.

- Electric Motor-to-Mechanical Drive: The use of an electric motor (l) to power the mechanical screw-and-linkage system influenced the early adoption of electric power in heavy industrial machinery, replacing steam or simple cable systems for greater precision and control.