The patent by Robert H. Gray of Lexington, Kentucky, describes a Cistern-Cleaner designed to remove mud, sediment, and other impurities from the bottom of ordinary cisterns. The main objects are to create a cleaner that can be operated without unnecessarily agitating or stirring up the sediment and one that can be readily adjusted to any convenient working position.

Invention and Mechanism

The device is essentially a hand-operated pump with a specialized, flexible suction head for targeted sediment removal.

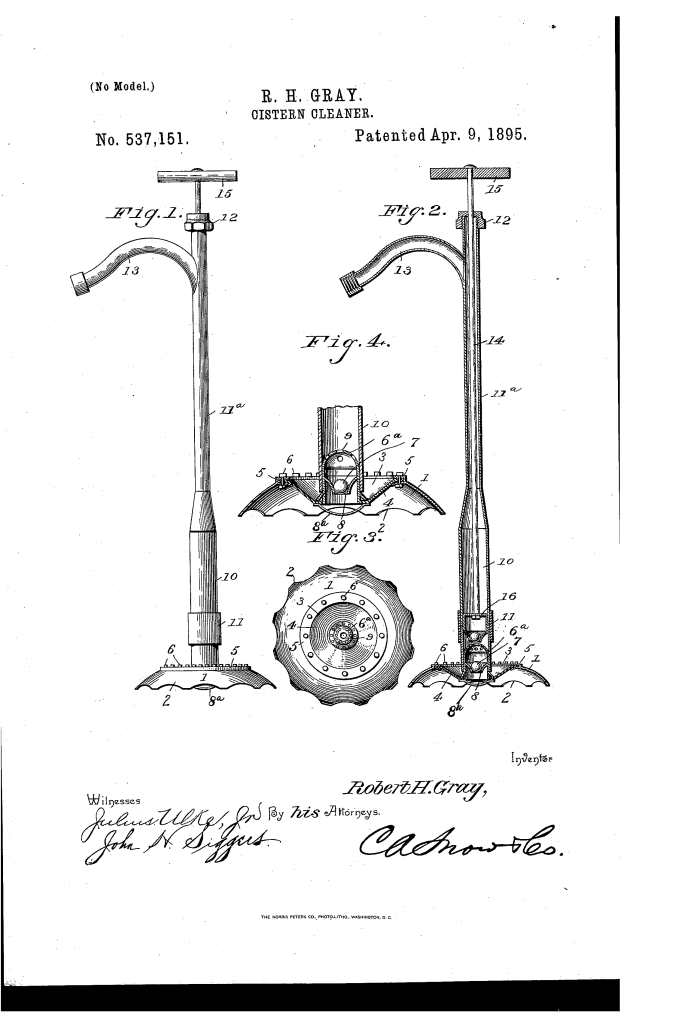

1. Suction Head Assembly

- Shallow Suction Cup (1): This cup is adapted to be placed flat upon the bottom of the cistern.

- Scalloped Edge (2): The cup’s lower edge is scalloped, forming openings to admit the passage of sediment and water into the cup.

- Flexible Cover (4): The top opening (3) of the cup is covered by a flexible, watertight cover (4), preferably made of rubber cloth, secured by a fastening ring (5).

- Valve Cage (6a): A valve cage is secured centrally to the flexible cover (4). It houses a ball valve (7) that works over a conical valve seat (8).

- Function: The ball valve acts as a check to prevent the return flow of water and sediment back into the cup after it has been drawn upward by the pump.

- Rest Bar (8a): A curved or bowed rest bar is secured to the bottom of the valve cage.

- Function: This bar rests on the bottom of the cistern to sustain the weight of the pump and relieve the flexible cover (4) of strain.

2. Pumping and Flexibility

- Pump Cylinder (10): The lower end of the pump cylinder is detachably fitted onto the valve cage (6a), so the valve cage acts as the valved lower end for the cylinder.

- Flexible Joint (11): The pump cylinder is provided with a flexible joint (11) slightly above its connection with the valve cage, preferably a short section of rubber tubing.

- Function: This joint allows the pump cylinder to be moved in any direction or bent out of alignment with the suction cup without disturbing the cup’s position or the seal on the cistern bottom. This is the mechanism for “readily adjusting” the pump to a convenient position.

- Plunger: A hand-operated plunger rod (14) with a handle (15) works through a stuffing box (12) and carries a valved plunger (16) inside the cylinder.

- Function: Reciprocating the plunger creates suction, drawing the sediment and water from the cup and elevating it through a discharge tube (11a) and spout (13).

3. Operation Principle

The cleaner is lowered until the suction cup rests flat on the bottom. The scalloped edge allows targeted sediment and water to enter the cup without stirring up the surrounding bottom layer. The operator can then pump the cylinder from an angle thanks to the flexible joint (11).

Historical Significance and the Inventor

Robert H. Gray’s 1895 patent is a practical solution to a common household problem in areas reliant on stored water, demonstrating a focus on public health and domestic utility.

- Cisterns and Water Quality: In the late 19th and early 20th centuries, many homes, especially in rural or non-municipal areas, relied on cisterns (underground tanks) to collect and store rainwater. Over time, mud, leaves, and sediment accumulated at the bottom, fouling the drinking water.

- Non-Agitation Method: The key significance of Gray’s invention is the design of the shallow suction cup and scalloped edge, which was intended to remove sediment in a targeted manner without unnecessarily stirring up the mud. This was a major improvement over cruder methods that often ruined the entire cistern’s water supply by making it cloudy.

- The Inventor (Robert H. Gray): Gray, residing in Lexington, Kentucky, was also the inventor of the Baling-Press (Patent No. 525,203). His work demonstrates a wide-ranging interest in solving common, practical problems, from large-scale agricultural commodity handling to essential domestic health and utility issues.

Relation to Current Items

Gray’s cistern cleaner utilizes principles common in modern pumping and cleaning equipment:

- Flexible Suction Heads: The use of a flexible joint (11) near the intake is fundamental to modern wet/dry vacuum cleaners and submersible pumps

used for debris removal, allowing the suction head to adapt to uneven surfaces without breaking the seal.

- Check Valves (Ball Valves): The ball valve (7) and valve cage is a simple, highly reliable form of check valve still used in millions of pumps and plumbing applications where flow needs to be restricted to one direction and the valve must tolerate debris.

- Suction-Based Debris Removal: The idea of using a shaped nozzle or cup to target debris without disturbing the liquid above is the basis for specialized aquarium cleaning syphons, swimming pool vacuum heads, and industrial slurry pumps.