The patent by James M. Mitchell of Jordan, Kentucky, describes certain new and useful Improvements in a Check-Row Corn-Planter (Patent No. 641,462, 1900). The object is to produce a check-row planter that is simple and durable, and, critically, has a mechanism for adjusting the planting mechanism independently of the machine’s movement to correct spacing errors.

Inventor Background: James M. Mitchell

James M. Mitchell was an inventor focused on improving agricultural efficiency. His invention addresses a critical problem in farming—maintaining perfectly square rows (“check-rows”)—which was essential for cultivating the crop in two directions, but was often ruined by wheel slippage or uneven turns. His solution provides a way for the farmer to quickly and precisely recalibrate the planting mechanism in the field.

Invention and Mechanism (Simplified)

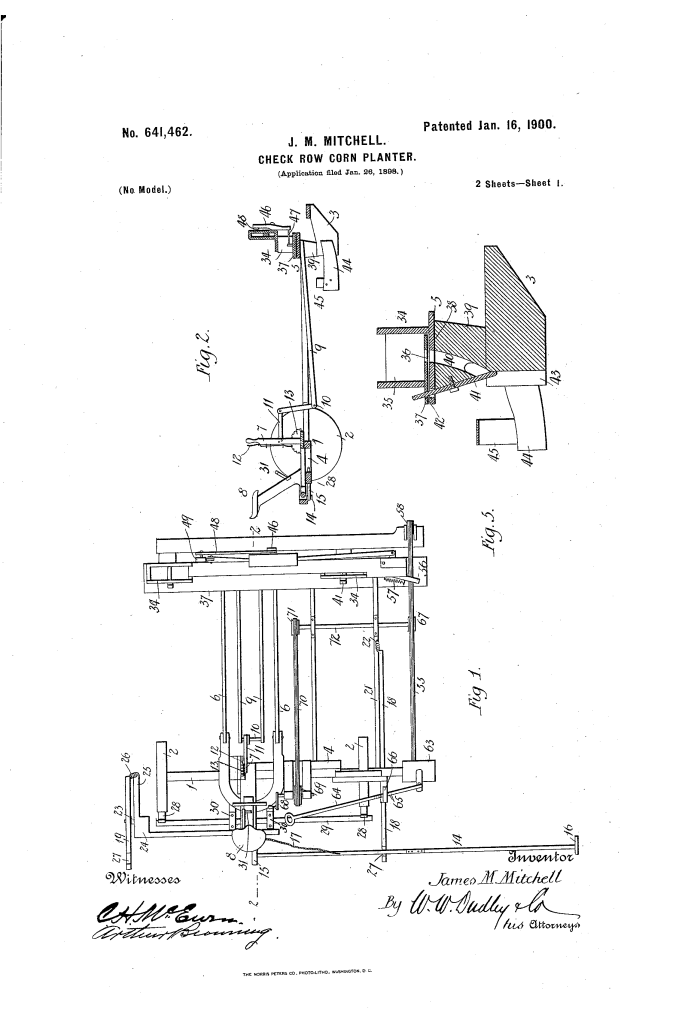

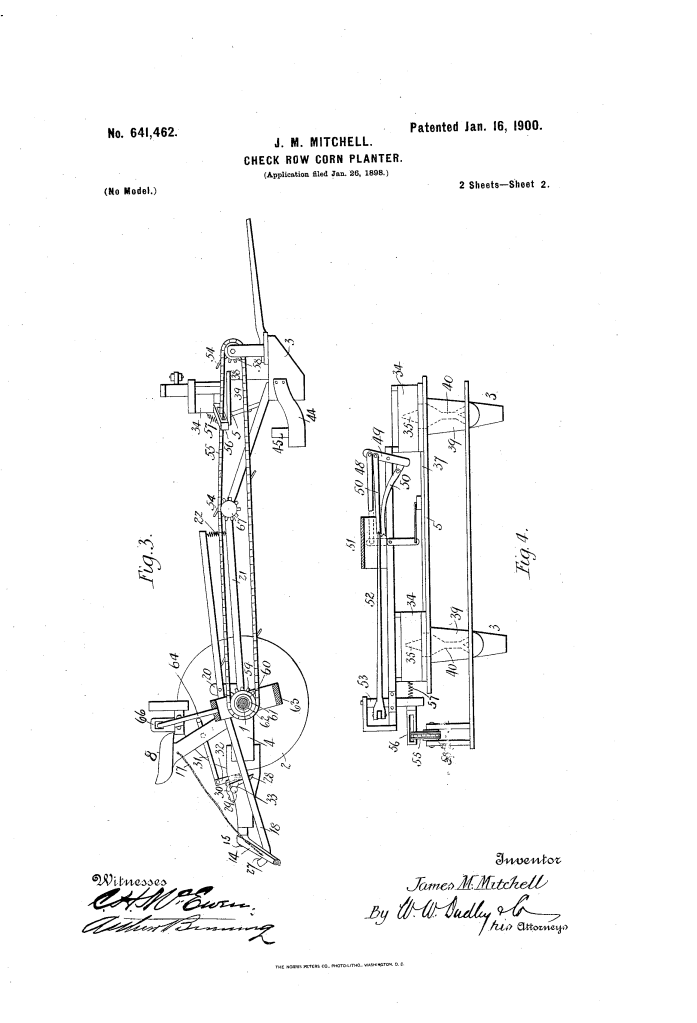

The planter is a wheeled, draft-animal-drawn machine featuring a lever-actuated steering system, a dual-outlet seed dropper, and a specialized drive system for timing.

- Seed Dropping:

- Hopper (34): Holds the seed.

- Slotted Plate (37): A plate that slides back and forth in the hopper bottom.

- Pivoted Gate-Lever (41): A lever whose bottom end swings to alternately open and close two discharge outlets ($40$) at the rear of the runner (3). The upper end of this lever is confined in a slot (42) in the sliding plate (37).

- Function: As the plate (37) reciprocates, the gate-lever (41) swings, causing an intermittent, alternating feed of seed through the two outlets.

- Driving and Timing:

- Power Source: Motion is taken from the rear wheels (2) to rotate an endless sprocket-chain (55), which is provided with several equally spaced spring-fingers (54).

- Reciprocating Rod (52): The spring-fingers (54) engage an arm (56) on a rock-shaft (53). This action causes the shaft to rotate partially, which uses a linkage (49, 46, 47) to reciprocate the slotted plate (37), timing the seed drop.

- Check-Row Function: The machine is designed so that the spring-fingers release the arm (56) at precise, timed intervals to drop the seed, creating a perfect row.

- Correcting Errors (Key Innovation):

- Clutch (60): The sprocket-wheel (59) driving the timing chain has a clutch (60) that can be thrown into or out of action using a hand-rod (64).

- Hand-Crank (68): A hand-crank (68) is mounted near the operator’s seat and is geared (69, 71) to another sprocket wheel (67) that engages the timing chain (55).

- Function: If the farmer notices the check-row pattern is off (e.g., due to wheel slippage), they unclutch the chain (60) from the axle. They then turn the hand-crank (68), which manually rotates the timing chain (55). This moves the spring-fingers (54) into the correct position to ensure regularity in the next seed deposit.

- Row Marker and Brake: The machine also includes a row marker (14) that can be shifted from side to side and a foot-lever controlled brake mechanism (31, 28).

Core Concepts Influenced by This Invention

Mitchell’s planter influenced subsequent agricultural and mechanical systems by pioneering in-process calibration of synchronized mechanisms.

- Manual Override for Synchronization: The most significant influence is the integration of a clutch (60) and a hand-crank (68) to allow the operator to manually adjust the timing (phasing) of the entire planting sequence without moving the main vehicle. This principle influenced the design of:

- Agricultural Equipment: All modern planters, seed drills, and fertilizer spreaders that use a clutch to disengage the drive and a manual crank/override to set the starting position of the seed meters.

- Industrial Timing Systems: Production lines and printing presses that require a mechanism to precisely re-phase or recalibrate a component’s timing chain or gear sequence during operation or setup.

- Segmented, Alternating Flow Control: The use of a single sliding plate (37) to swing a gate lever (41) and alternately open two separate outlets influenced the design of various metering and dosing mechanisms requiring high-speed, sequential fluid or granular discharge.

- Inertia-Driven Mechanism (Timing): The use of sprocket-chain fingers (54) that are carried forward and snap past the operating arm (56) influenced the design of simple, low-maintenance mechanical indexing and trigger systems.