Casting Composite or other Wheels (Elbert R. Robinson, No. 594,286)

The patent by Elbert R. Robinson of Chicago, Illinois, describes a method and apparatus (mold) for Casting Composite or other Wheels (Patent No. 594,286, 1897). The primary objects are to cast wheels economically and effectively, specializing in composite wheels where the outer sides are of one metal (e.g., iron or steel) and the interior connecting portions are of a different metal (e.g., brass or copper) cast upon the sides. The method also enables the successful casting of high-conductivity metals (like brass or copper) into the grooves of iron trolley wheels.

Inventor Background: Elbert R. Robinson

Elbert R. Robinson was an inventor whose work focused on improving the durability and performance of electric railway components.

- Focus on Electric Rail: Robinson was also the inventor of an improved Electric-Railway Trolley (Patent No. 505,370, 1893), which used a three-pulley system to prevent dewiring. His work consistently targeted the major mechanical failures in the trolley system.

- The Wheel Problem: This patent directly addresses the issue of trolley wheels, which needed to be durable (iron/steel) but also highly conductive (copper/brass) for efficient power transfer. Robinson’s solution involved creating a new manufacturing method (composite casting) to marry these two necessary properties in a single, robust wheel.

Invention and Mechanism

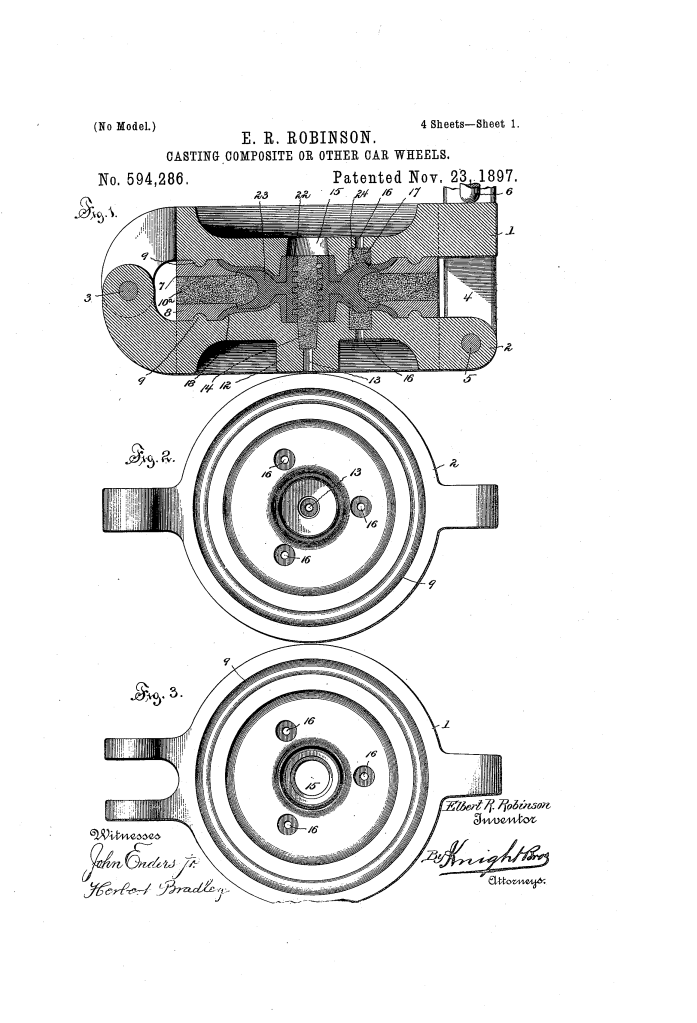

The invention is a specialized, multi-part, ventilated mold used to cast molten metal onto pre-formed metal disks.

1. Composite Wheel Mold Structure

- Three-Part Mold: Consists of a hinged top (1) and bottom (2) mold section, and a central metal ring (7).

- Metal Ring (7): This ring is the mold for the wheel’s groove and inner filling. It has a radial cavity () between its faces to receive a filling of sand (10).

- Function (Ventilation): The sand filling (10) makes the mold “practically a ventilated mold,” allowing the gases generated in casting to escape easily, which is crucial for obtaining perfect, clean castings when dealing with dissimilar metals.

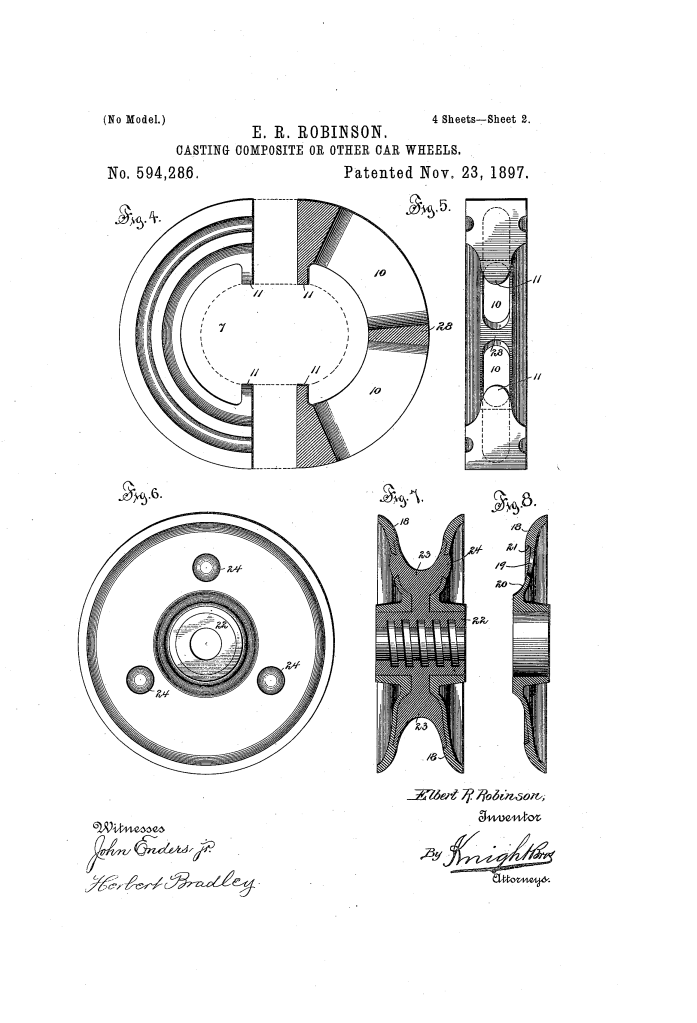

2. Composite Casting Method (Key Innovation)

- Outer Disks (18): Two pre-formed metal disks (e.g., iron or steel) that form the outer sides/flanges of the wheel are placed into the mold.

- Locking Holes (19): Each disk (18) has a series of countersunk holes (19) in its web (20).

- Function: When the central filling metal is poured, it enters these holes, forming studs (24) that securely lock the outer disks to the central filling (23), fixing them relative to each other.

- Casting: Molten metal (e.g., brass or copper) is poured into the space between the disks. It forms:

- A bushing (22) around the sand core (14) for the axle-bearing.

- A filling (23), which is the intermediate portion of the wheel, including the groove surface.

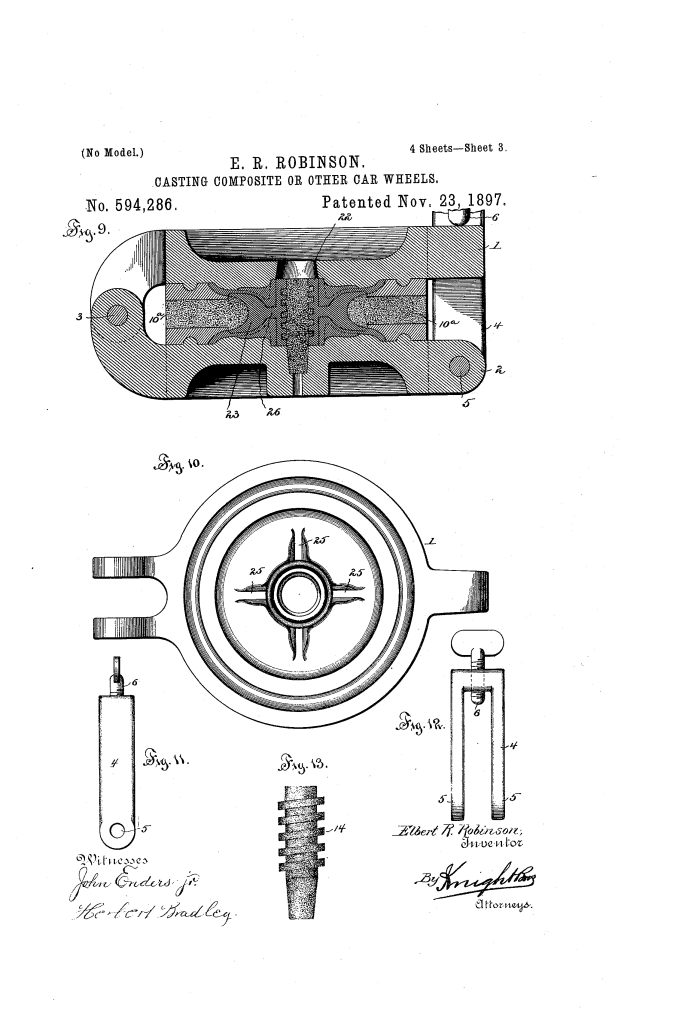

3. Versatility

- Spoked Wheels: The mold can be modified with spoke-grooves (25) to cast wheels with radial fins or spokes.

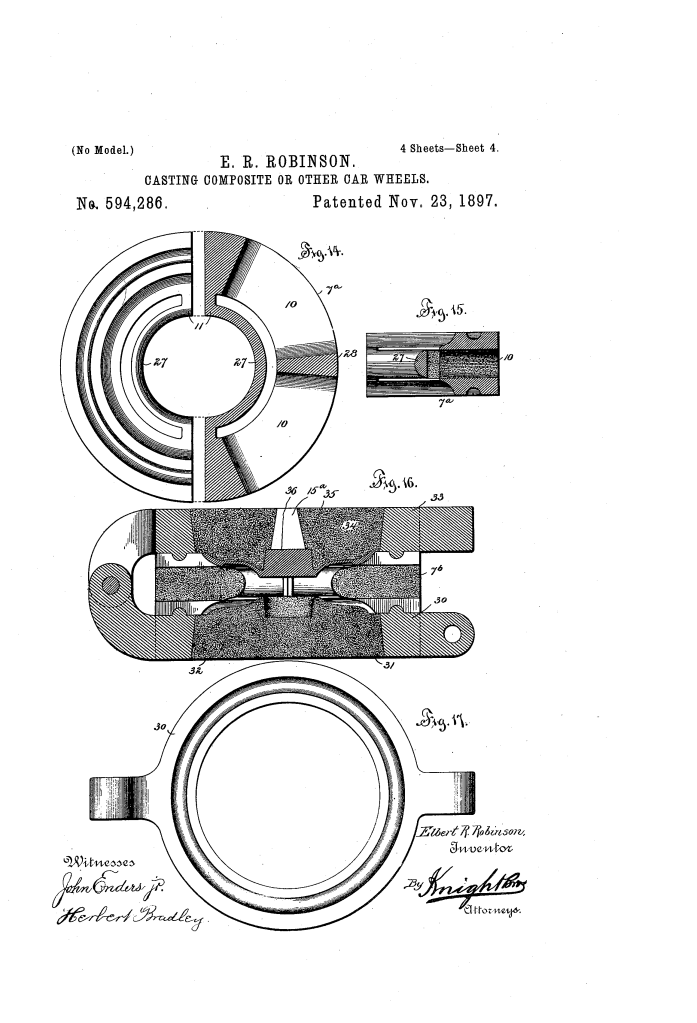

- Solid Wheels: The principles of the ventilated mold can be adapted to cast solid wheels by using patterns to shape the sand fillings in the top and bottom sections.

Concepts Influenced by This Invention

Robinson’s casting method influenced subsequent metallurgy and manufacturing by demonstrating a reliable, large-scale process for creating structurally integrated parts from dissimilar materials.

- Composite and Bi-Metallic Casting: The core innovation of casting a second metal onto a pre-formed structural component (the disks 18) and using mechanical anchors (the countersunk holes 19) to securely lock the materials together is the foundational concept for modern composite manufacturing and bi-metallic castings used in high-performance brakes, specialized rail wheels, and industrial machinery where materials with different properties (e.g., strength vs. conductivity) must be combined.

- Molding for Ventilation: The emphasis on creating a ventilated mold using a sand filling in the metal ring (7) to allow gas escape influenced casting practices. Proper mold venting is a non-negotiable requirement in modern metal casting to achieve high-quality, defect-free parts, especially when dealing with volatile or dissimilar alloys.

- Quick-Set, Reusable Molds: The design of a heavy-duty, hinged, and clamped mold (1, 2, 4) intended for repeated use influenced the development of permanent and semi-permanent mold casting techniques in industrial settings, where production speed and mold longevity are critical.