Casket-Lowering Device (Albert C. Richardson, No. 529,311)

The patent by Albert C. Richardson of South Frankfort, Michigan, describes an improved Casket-Lowering Device designed to perform the solemn duty of lowering a casket safely and reliably into a grave. The invention aims to prevent the casket from “falling,” which, as the specification notes, “causes such horror to those who respect the dead,” and also to keep dirt from falling into the grave.

Invention and Mechanism

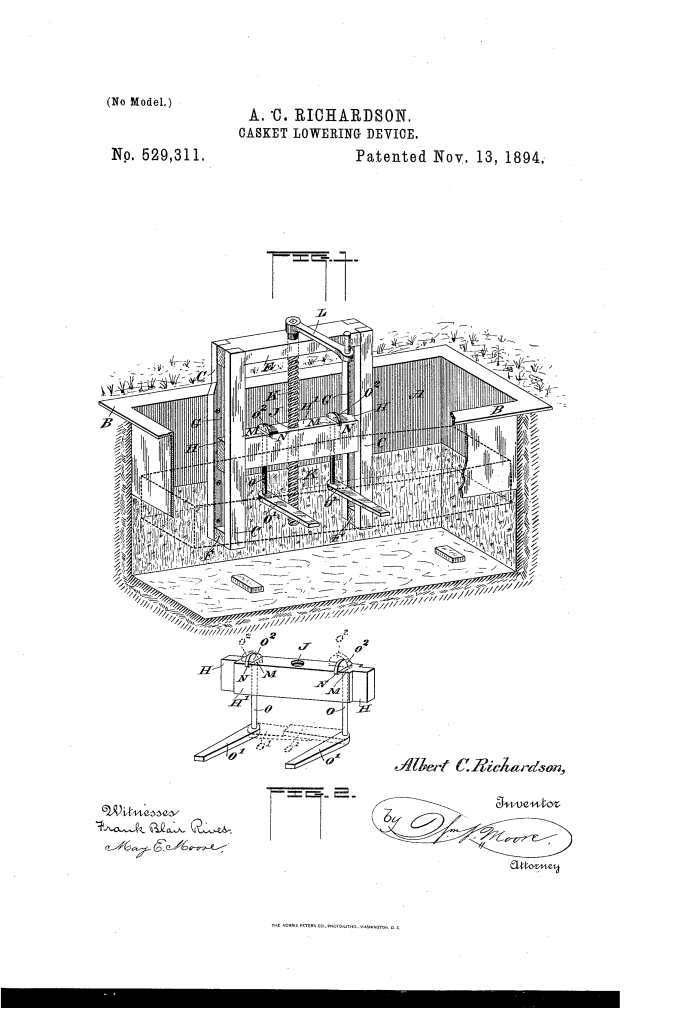

The device is a combination of a protective casing and a mechanical screw-driven lifting/lowering apparatus.

- Casing/Protector (A):

- A shield, preferably made of sheet metal, in the form of an open rectangular casing with an outward-facing rim or flange (B).

- Function: The casing fits closely into the grave ditch/trench, with the rim resting on the surface of the ground. This shield prevents dirt from falling from the edges of the ditch onto the casket or into the grave during the service.

- Lowering Mechanism (Frame, Head, and Screw):

- Frame (C): Secured to one side of the casing (A), consisting of standards (D), a top cross-piece (E), and blocks (F), which form guides or ways (G).

- Follower/Head (H′): A block that fits within the guides (G) and is adapted to move vertically. It has a centrally threaded opening (J).

- Traveling Screw (K): A large screw that passes through the cross-piece (E) and engages the threaded opening (J) of the head (H′). A crank or crank wheel (L) is secured to the top of the screw.

- Function: Turning the crank (L) rotates the screw (K), which slowly and precisely moves the head (H′) up or down within the frame (C), providing a controlled lowering of the mechanism.

- Casket Support and Release:

- Supporting Rods and Arms (O): Rods arranged in openings (M) in the head (H′). At their lower ends, they have casket-receiving arms (O′).

- Locking Mechanism: The upper ends of the rods have enlargements (O2) that engage with notches (N) on the upper face of the head (H′). When engaged, the enlargements prevent the rods from turning.

- Release Function: After the casket is fully lowered, the operator uses a suitable grasping instrument to disengage the enlargements (O2) from the notches (N). The rods can then be turned (as shown in dotted lines in Fig. 2), moving the arms (O′) out from under the casket.

Historical Significance and the Inventor

Albert C. Richardson’s 1894 patent reflects a significant step toward professionalizing and solemnizing the burial process in late 19th-century America.

- Dignity in Burial: The primary motivation, as stated in the specification, was to prevent the “horror” caused by accidental drops or the crude appearance of soil falling into the grave. This underscores a growing cultural demand for solemnity, reverence, and mechanical perfection in funeral rites. The device was meant to replace simple ropes or web straps, which were unreliable and often jarring.

- Early Funeral Equipment: This invention is an early example of specialized, purpose-built funeral equipment. Prior to such devices, the lowering of caskets was often a manual, sometimes haphazard, task. Richardson’s mechanical device offered a reliable, aesthetically acceptable, and dignified solution, contributing to the establishment of funeral directing as a specialized service.

- The Shield/Casing (A): The inclusion of the sheet-metal shield is a key innovation often overlooked. It addressed the common problem of a newly dug grave’s edges crumbling, ensuring a tidy visual appearance for the bereaved.

Relation to Current Items

Richardson’s invention is the direct conceptual ancestor of all modern, commercially available casket-lowering devices:

- Modern Funeral Equipment: Every funeral home today utilizes a sophisticated version of the mechanical lowering device. Modern equipment uses electric or hydraulic motors, brake systems, and robust web straps instead of screws and rods, but the function is identical: a controlled, silent, and reliable means of vertical translation.

- The “Lawn Protector” Concept: The shield/casing (A) is the predecessor to modern grave tents, canopy skirts, and green carpet runners that are used to conceal the freshly turned earth and provide a professional, tidy appearance at the graveside.

- Controlled Mechanical Movement: The use of a traveling screw (K) to achieve slow, precise linear motion is a principle used in countless applications requiring fine control, such as jacks, laboratory stages, and machine tool tables, emphasizing the robust, utilitarian nature of the mechanism.