Carrier-Chain (William Douglass, No. 789,122)

The patent by William Douglass of Phillipsburg, Kansas, describes an improvement in a Carrier-Chain (Patent No. 789,122, 1905). This invention is a key subsystem of his Self-Binding Harvester, specifically designed to compress and convey straw or similar strands of material from the cutting apparatus to the tying mechanism. The objects are to prevent material from escaping, becoming entangled, or clogging the system.

Inventor Background: William Douglass

William Douglass was an inventor focused on large-scale agricultural machinery. His work addressed the critical mechanical challenge of reliably handling and transporting loose, fibrous crop material (straw) without jamming or loss, which is essential for the continuous, high-speed operation of a harvester.

Invention and Mechanism (Simplified)

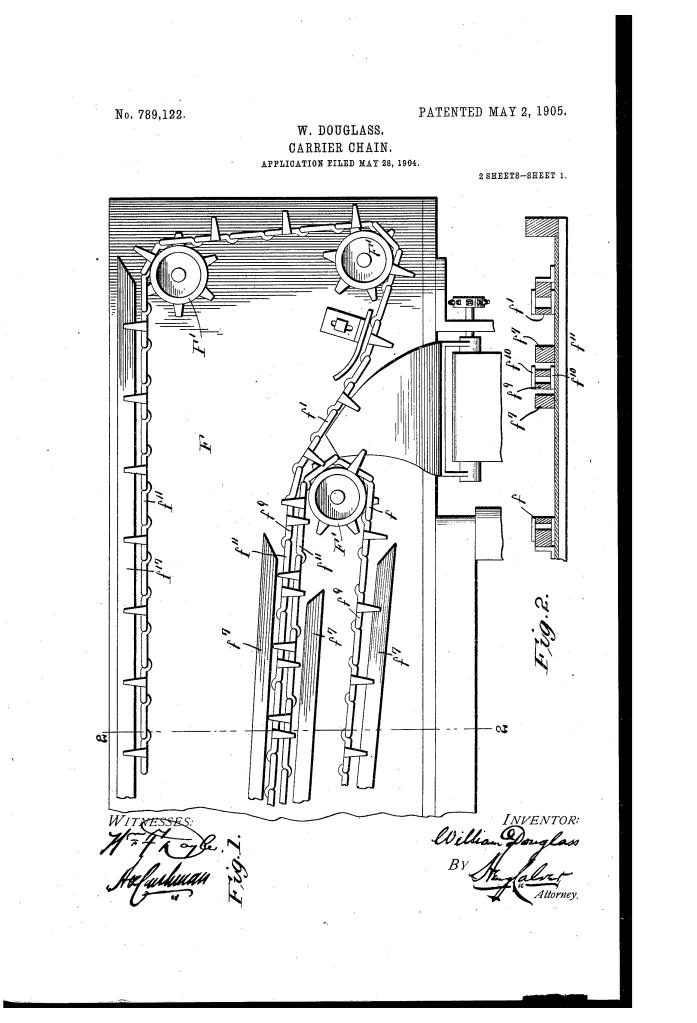

The carrier is a pair of interlocking chains that form a complete tube around the material, featuring integrated mechanical brushes to prevent entanglement.

1. Interlocking Chains (Key Innovation)

- Dual Chains: The conveying system uses two separate chains that lie side by side in close relation.

- Carrier-Links: One chain ($f$) is composed of alternating plain links and carrier-links. These carrier-links have lugs projecting at right angles from the sides.

- Interlocking Action: The two chains are arranged so that the lugs of one chain interlock by straddling the plain links of the opposing chain.

- Function: When the chains come together, they form a completely enclosed channel around the straw, preventing the material from escaping, even under compression.

2. Anti-Entanglement and Self-Cleaning System

- Spring-Plates: Small spring-metal plates are secured to the rear end of each link (on the outer chain $f$). These plates cover the openings in the links.

- Flexing Actuation: The knuckle (hinge joint) of each chain link has a special flat bearing surface.

- Function: When the chain rounds the sprocket-wheel and is flexed, the knuckle of the next link projects through the opening and physically pushes the free end of the spring-plate outward.

- Result (Mechanical Brushing): This outward movement serves to break or disentangle any strands or straw-beards that may have caught in the links, actively sweeping the link clean and preventing the material from being carried around and entangling the sprocket-wheels.

3. Guidance and Structure

- Guide-Rails: Fixed guide-strips hold the two chains in close, interlocked, and compacting relation throughout their straight run.

Concepts Influenced by This Invention

Douglass’s carrier-chain influenced subsequent industrial material handling systems by pioneering active self-cleaning and structural interlocking for containment.

- Active Mechanical Self-Cleaning: The most significant influence is the design that uses the flexing of the chain itself over a sprocket to trigger a mechanical sweeping action (the knuckle pushing the spring-plate outward). This principle is used in modern:

- Agricultural Conveyors: For harvesting sticky or fibrous materials (like cotton or biomass).

- Industrial Bucket Elevators: Where the chain or belt mechanism is designed with built-in features to dislodge adhering material as it rounds the terminal wheel.

- Structural Interlocking for Conveyance: The use of lugs to mechanically interlock two parallel chains to form a closed envelope around the material influenced the design of specialty industrial conveyors used for:

- Compacted Transport: Moving loose material in a compressed state.

- Controlled Delivery: Ensuring material does not shift or escape during transport between processing points.

- Modular Link Design: The design contributed to the engineering of specialized chain links with integrated secondary functions (the spring-plate) for specific material handling tasks.