Car-Coupling (Charles V. Richey, No. 584,650)

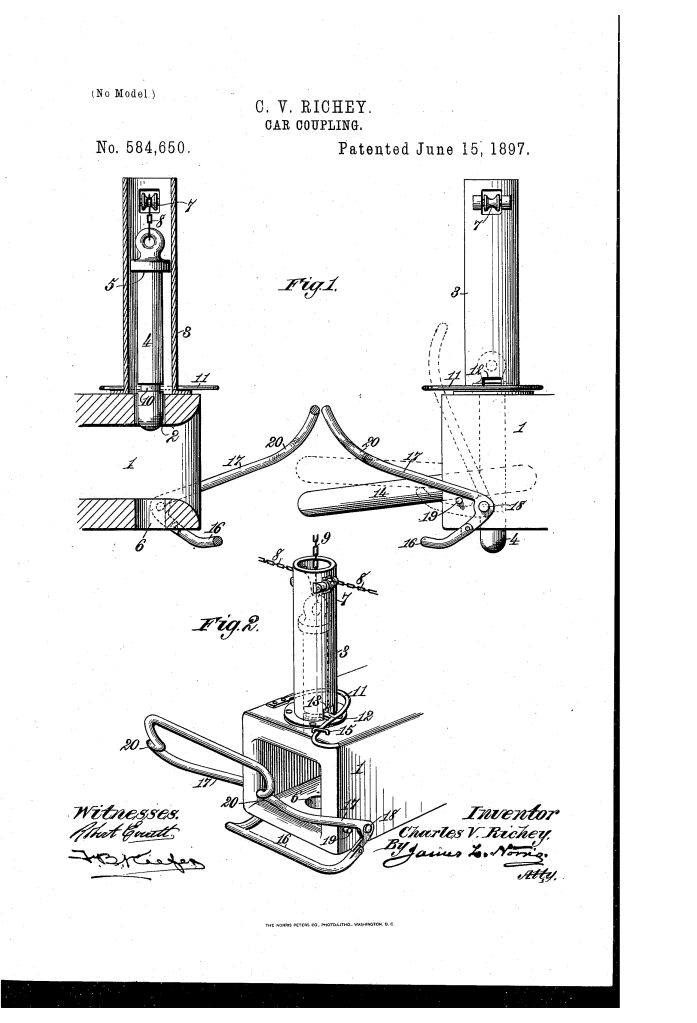

The patent by Charles V. Richey of Atlanta, Georgia, describes improvements in a Car-Coupling (Patent No. 584,650, 1897). The invention is a set of attachments designed for easy and immediate application to ordinary pin-and-link draw-heads. The object is to provide an automatic coupling system that includes pin-retention, link-lifting, and pin-release—all actuated by contact with the opposing draw-head, eliminating the need for the attendant to enter between the cars.

Inventor Background: Charles V. Richey

Charles V. Richey was an African-American inventor known for his focus on railway and safety mechanisms. He also patented a railway switch (No. 592,448) and a fire-escape bracket (No. 596,427). This patent is part of the final push toward safer rail travel, offering an automated retrofit solution for the still-common, dangerous pin-and-link couplers, which were soon to be federally mandated out of use.

Invention and Mechanism

The coupler uses mechanical attachments to automate the three steps of coupling: lifting the link, holding the pin, and dropping the pin.

1. Pin Retention and Release

- Pin Guide (3): A tubular guide secured to the top of the draw-head (1) around the pin-hole, housing the coupling-pin (4).

- Spring-Latch (11): A stout spring-wire secured to the draw-head. It has a latching projection (12) that engages an annular groove (10) near the base of the elevated pin (4).

- Function: This holds the pin in an elevated (inoperative) position. The annular groove ensures the pin is locked regardless of its rotation.

- Release: The pressure of an opposing draw-head, or the bail-shaped lever, forces the spring-latch (11) outward, releasing the pin to drop.

2. Link Lifting and Activation (Key Innovation)

- Bail-Shaped Lever (17): A large lever pivoted to the sides of the draw-head, normally projecting upward and forward beyond the draw-head mouth.

- Link-Lifter (16): A folding attachment pivotally connected to the lower, hook-shaped ends of the lever (17).

- Function: As two cars approach, the levers (17) on both draw-heads strike each other and are simultaneously swung backward. This rearward movement causes the attached link-lifter (16) to elevate the link (14) into a proper position to enter the opposite draw-head.

3. Automatic Coupling Sequence

- Link Inserted: An open link (14) is secured by the lowered pin of one draw-head. The pin on the other draw-head is held elevated by the spring-latch (11).

- Contact and Lift: The two cars approach. The levers (17) strike and swing back, lifting the link (14) into alignment.

- Pin Release: As the levers swing backward, a bend (

) on one lever (17) hits and forces the spring-latch (11) outward on the opposing draw-head, releasing the elevated pin (4).

- Locking: The released pin (4) drops into engagement with the link (14), completing the automatic coupling.

- Relief: As the draw-heads fully compress, the link-lifters (16) fold backward, relieving strain on the lever pivots.

Concepts Influenced by This Invention

Richey’s coupling device influenced subsequent mechanical safety designs by pioneering sequential, contact-actuated automation in railway hardware.

- Sequential Automation via Contact: The core concept of a single, external contact (lever 17) initiating a necessary sequence of actions (lift link

release pin) is a fundamental principle of automated safety systems. This influenced designs where an external force triggers a set of internal, timed events.

- Self-Actuating Linkage (Over-Center): The use of a simple, robust bail lever (17) that translates rearward force into a vertical lift (for the link) and a lateral push (for the pin latch) influenced the design of various mechanical linkages and clutch systems requiring multi-directional actuation from a single input.

- Automatic Pin Retention: The use of a spring-latch (11) and an annular groove (10) to hold the coupling pin elevated is a foundational element of modern quick-release hardware. This design principle ensures the pin is locked regardless of its rotation, making the operation simple and reliable.

- Modular Retrofitting: The strategy of creating an inexpensive set of attachments to upgrade existing, primitive hardware (the pin-and-link draw-head) influenced the design philosophy for modular and aftermarket safety upgrades in many industrial sectors.