Broom Moistener and Bridle (Lyde W. Benjamin, No. 497,747)

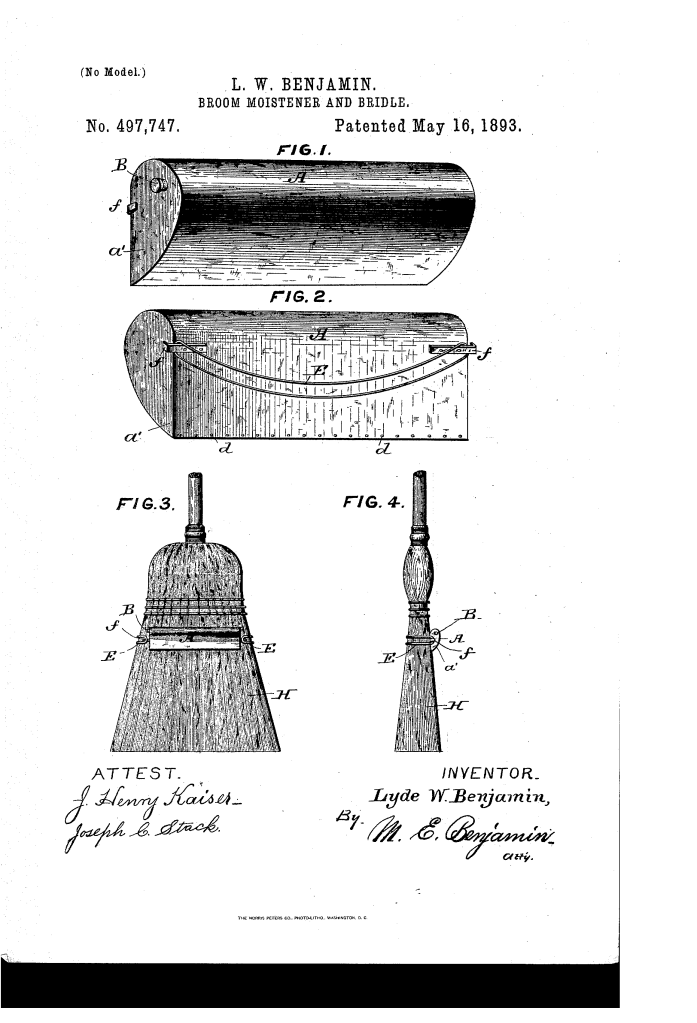

The patent describes a Combined Broom Moistener and Bridle designed to be secured to the sweeping portion of a broom. Its purpose is to moisten the broom to lay dust, and simultaneously act as a bridle (clasp) to bind the broom straws, extending the broom’s life and improving its sweeping efficiency.

Invention and Mechanism

The device is a simple, non-mechanical accessory that relies on capillary action and the motion of sweeping:

- Reservoir (A): A metal box, preferably tin, with one face (a) being flat to rest against the side of the broom. The main body tapers downward, making it thinner at the bottom (substantially triangular or “half heart shaped” in cross-section).

- Moistening Mechanism: The flat face (a) of the reservoir, near its lower edge, has a series of minute perforations (d).

- The perforations are designed to be so small that water will not flow or drip when the broom is at rest.

- When the broom is in use, the swinging motion and contact with the floor is sufficient to shake out a small amount of water, which permeates the broom straw.

- The tapering shape ensures that nearly all the water can be exhausted before refilling.

- Filling and Sealing: A filling-hole (B) is located at one end and is closed after the reservoir is filled, ensuring the only exit point for water is through the minute perforations. No feed tubes or stopcocks are required.

- Bridle and Attachment: A strap (E), preferably rubber for easy adjustment, is attached to hooks (f) at each end of the reservoir.

- This strap wraps around the broom and back to the reservoir, securely clamping the box to the broom.

- This combination of the box and strap acts as a bridle or clasp, encircling the broom straw to confine them and prevent them from spreading, being displaced, or broken off, thereby causing the broom to last longer.

Historical Significance and the Inventor

The patent by Lyde W. Benjamin of Boston, Massachusetts, and assigned to Miriam E. Benjamin (likely his wife), is significant as a specialized improvement in domestic cleaning tools during a period of intense focus on household efficiency and health.

- Public Health and Dust Control: In the late 19th century, understanding of hygiene and airborne diseases was increasing. Dust in the home was not just a nuisance but a source of germs and irritation. The primary function of the moistener—to prevent dust from rising—reflects a growing public health concern for keeping indoor air clean.

- The Problem of Broom Wear: Brooms made of corn straw were a staple but wore out quickly as the straws spread and broke. Accessories that extended the life of these tools were valuable, and the bridle function offered a cost-saving benefit to households.

- Miriam E. Benjamin: While Lyde W. Benjamin is the inventor, the assignment to Miriam E. Benjamin is notable. Miriam E. Benjamin was an African-American school teacher and attorney who held a major patent in her own right (Patent No. 362,902 for a “Gong and Signal Chair” used in hotels and hospitals), making her one of the earliest African-American female inventors. Her involvement, even as assignee, links this practical household invention to a pioneering figure in American history.

Relation to Current Items

The dual functionality of the Broom Moistener and Bridle—combining a container with a tool-reinforcing band—is a design principle still used in cleaning and maintenance equipment today:

- Broom Bridles: While many modern brooms have integrated synthetic heads, the concept of a metal or plastic bridle/clasp around the straw or synthetic bristles is still widely used in commercial and heavy-duty push brooms to keep the bristles rigid and prevent spreading.

- Moistened Floor Tools: The objective of laying dust with moisture is the foundation of the modern mop, dust mop, and electrostatic cleaning cloth. Benjamin’s device was essentially a non-electric precursor to the modern spray mop , which uses a self-contained reservoir and a controlled release mechanism to dampen the cleaning surface or implement.

- Passive Damping Systems: The design, which uses minute perforations and relies on motion to release water (no valves or moving parts), is an early example of a passive flow-control system, similar to the principle of a wick or controlled capillary action used in some modern air fresheners or humidifiers.