Breech-Loading Cannon (Eugene Burkins, No. 649,433)

The patent by Eugene Burkins of Chicago, Illinois, describes a new and useful Breech-Loading Cannon (Patent No. 649,433, 1900). The primary object is to provide a construction specifically adapted for handling heavy ammunition to achieve a much greater rapidity of fire than previously possible in large-caliber guns.

Inventor Background: Eugene Burkins

Eugene Burkins was an inventor focused on high-speed, heavy-duty mechanical systems, particularly in military and industrial applications.1 His invention addresses the logistical bottleneck of loading large ammunition, which traditionally slowed the rate of fire, by automating the entire handling and ramming process.

Invention and Mechanism (Simplified)

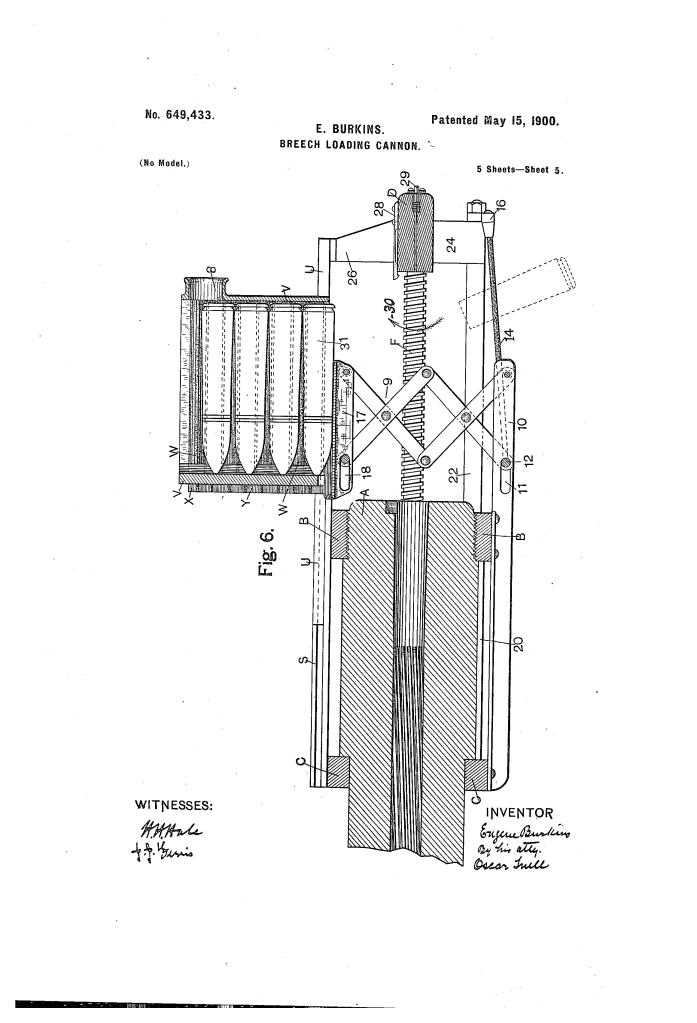

The cannon features a screw-driven, combined breech-block/rammer and an automated, roller-fed magazine, all synchronized for continuous rapid fire.

1. Screw-Driven Breech-Block/Rammer

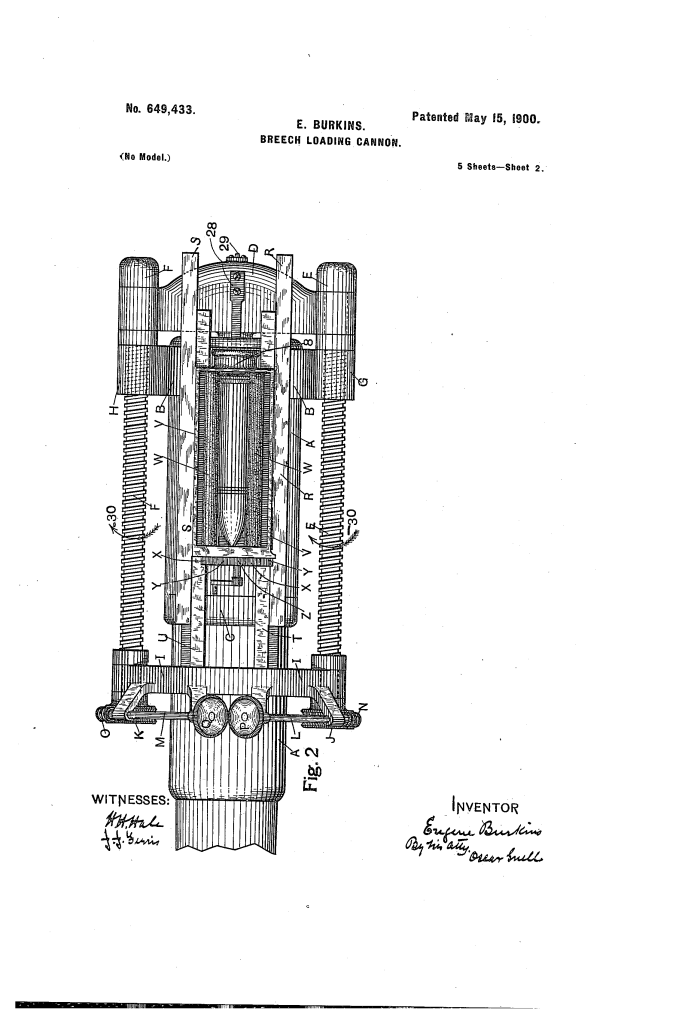

- Side Screw-Shafts (E, F): Heavy screw-shafts run along both sides of the cannon breech.

- Breech-Block (D): The breech-block is attached to the rear ends of these screw-shafts (E, F).2

- Function: The block serves a double purpose: when closed, it is the breech-block (locking the gun); when opening/closing, it acts as a powerful rammer to force the heavy cartridge into the chamber.

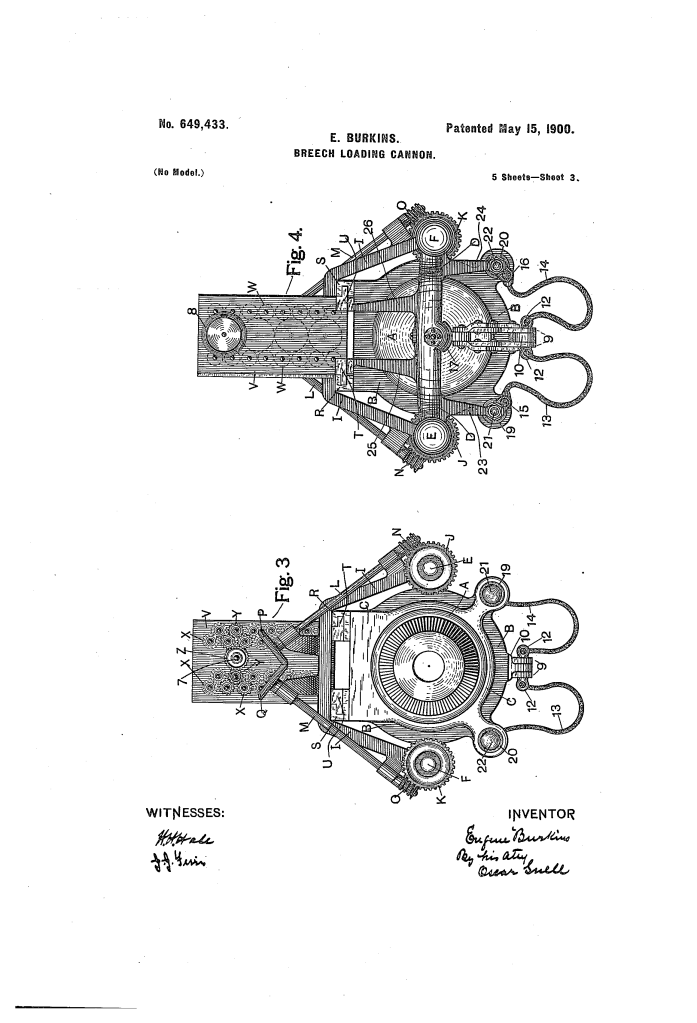

- Synchronized Drive: The two screw-shafts (E, F) are connected by worm-gears (J, K) and inclined shafts (L, M) linked by bevel gears (P, Q), ensuring they rotate in unison.3 Power is applied to one of the inclined shafts.

2. Automated Cartridge Magazine

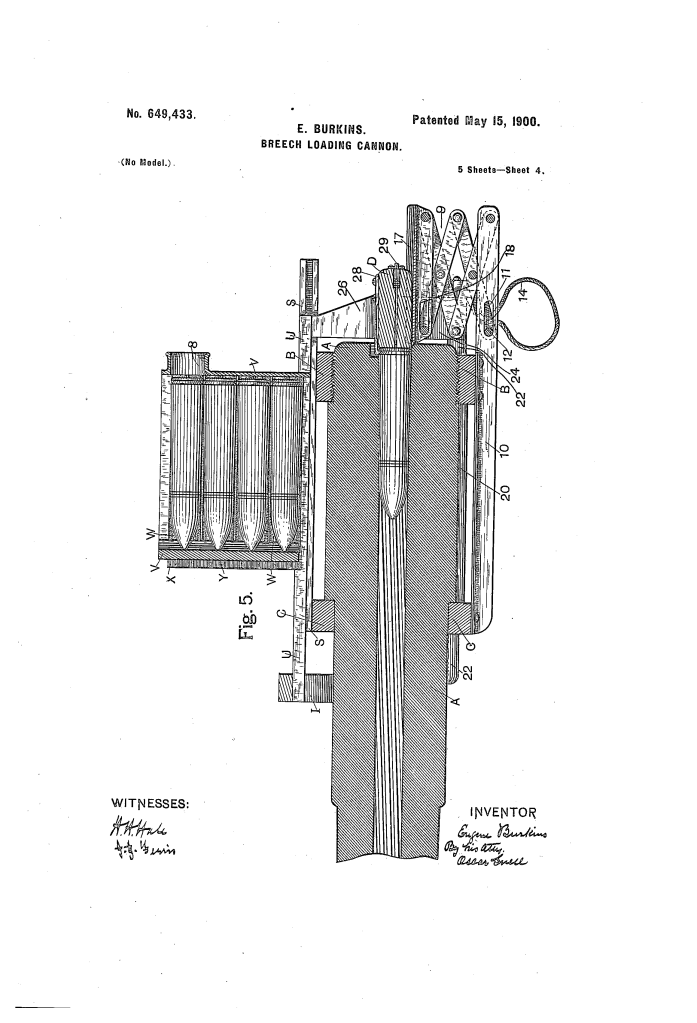

- Bottomless Magazine (V): A large case mounted above the breech.

- Roller Walls (W): The magazine’s internal walls are lined with a series of rubber-coated rollers (W) arranged in vertical rows on each side.

- Function: These rollers are geared together to rotate in opposite directions, designed to gently but positively convey the heavy ammunition downward by friction and gravity.4

3. Cartridge Handling and Ejection (Key Innovation)

- Cartridge-Receiver (17): A small, concave receiver is mounted on a lazy-tongs linkage (9) beneath the magazine.5

- Timed Movement: The lazy-tongs are connected to the breech-block (D) via flexible wire ropes (13, 14).

- Opening/Ejection: As the breech-block moves backward (retracted by the screws), the ropes straighten and activate the lazy-tongs, causing the receiver (17) to rise rapidly (Fig. 6). The spent shell is thrown out by a spring extractor (28).

- Loading: The receiver rises to the level of the magazine, receives the lowest cartridge, and then descends as the breech-block moves forward. The breech-block itself then pushes the cartridge from the receiver into the chamber (rammer function).

Concepts Influenced by This Invention

Burkins’s cannon influenced subsequent heavy-duty automation by pioneering integrated, timed handling for massive, discrete objects.

- Screw Drive for High-Force/Precision Actuation: The use of heavy-duty screw-shafts (E, F), driven by high-torque worm-gears (J, K), to perform the critical function of locking and ramming influenced the design of modern:

- Industrial Presses: Heavy-duty linear actuators and screw-jacks requiring precise, high-force application.

- Heavy Machinery Closures: Locking mechanisms for large doors, hatches, or molds.

- Automated Component Feeding (Rubber Rollers): The magazine using rubber-coated rollers rotating in opposite directions to positively feed large, heavy objects (cartridges) influenced the design of automated feeders, conveyors, and dispensers for heavy or delicate parts in manufacturing, where friction must be controlled to prevent damage or jamming.

- Kinematic Synchronization (Lazy-Tongs): The integration of the lazy-tongs linkage (9), actuated by the main drive (breech-block) to raise and lower the cartridge receiver, influenced the design of automated pick-and-place and loading mechanisms that require a component to move along a variable, specific path synchronized with the main machine cycle.

- Integrated Rammer/Closure: The consolidation of the breech-block and the rammer function into one screw-driven piece influenced the design of modern high-speed industrial closures and filling machines.