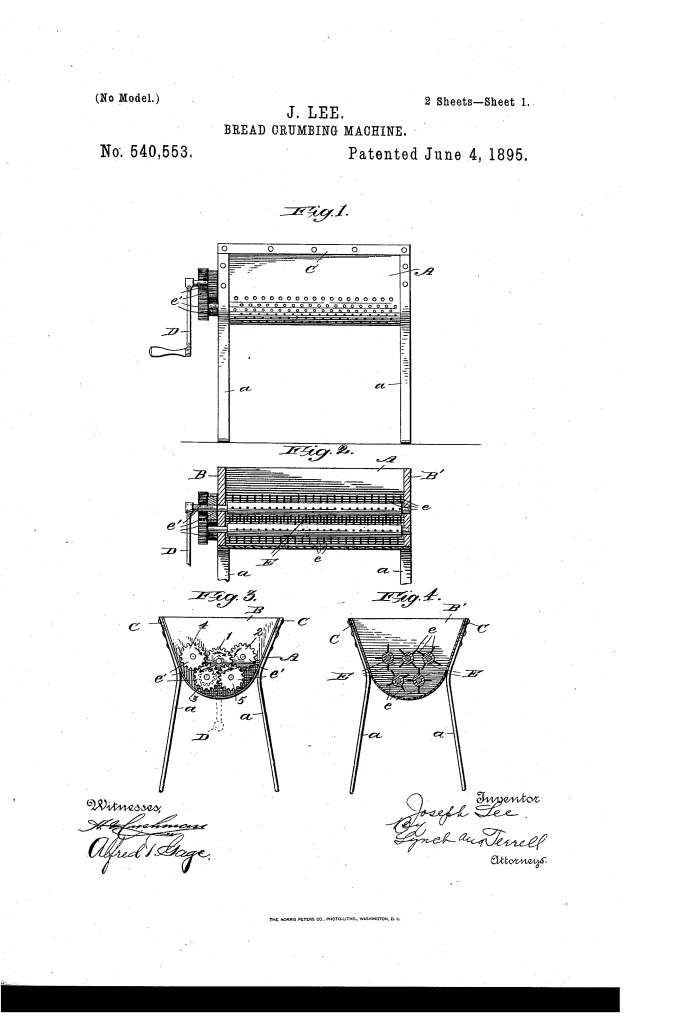

Bread-Crumbing Machine (Joseph Lee, No. 540,553)

The patent by Joseph Lee of Auburndale, Massachusetts, describes an improved Bread-Crumbing Machine. The machine is designed to quickly and efficiently reduce bread into crumbs, particularly addressing the difficulty of crumbing new bread, which tends to roll rather than crumble when crushed.

Invention and Mechanism

The machine uses a trough containing multiple rotating shafts with tearing fingers, geared to ensure continuous processing of the material until the required fineness is achieved.

- Trough and Discharge:

- Trough (A): The main body, preferably formed of sheet metal, has diverging sides (inverted cone shape in cross-section) and a rounded bottom that is perforated.

- Function: Crumbs fine enough to pass through the perforated bottom fall into a receptacle below; coarser material is retained for further processing.

- Crumbing Mechanism (Shafts and Fingers):

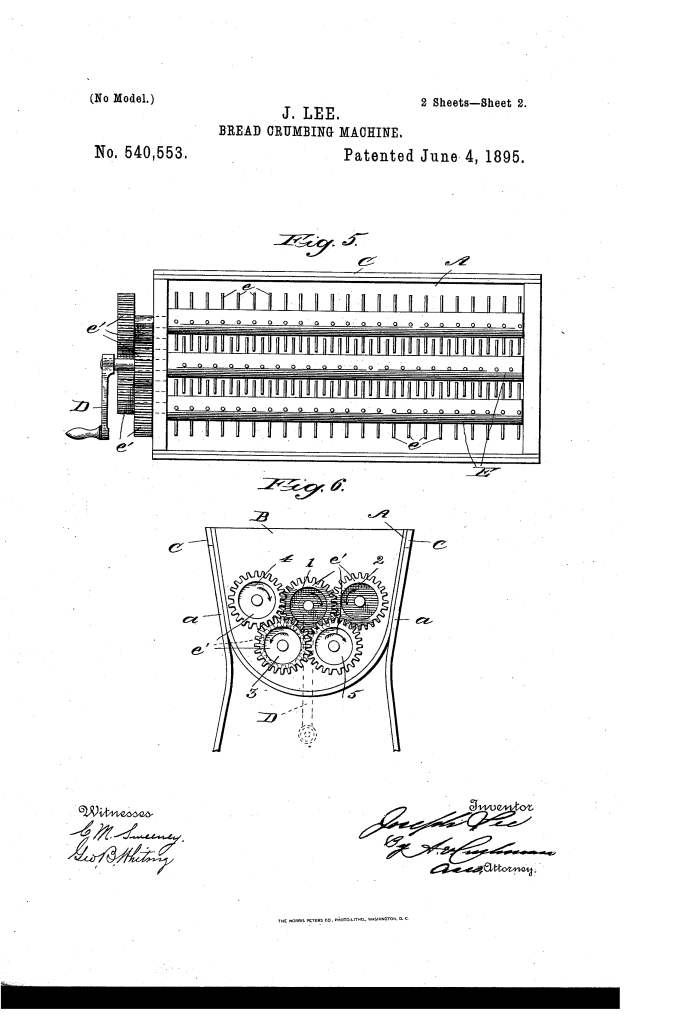

- Shafts (E): A series of horizontal shafts (preferably five) running the length of the trough, arranged in two horizontal rows (three shafts in the upper row, two in the lower).

- Crumbing Fingers (): Radially disposed crumbing or tearing fingers on the shafts are arranged to intermesh with one another.

- Gearing and Circulation (The Key Innovation):

- Pinions (): The ends of the shafts (E) project through the end pieces (B) and are equipped with pinions that mesh with one another (see Fig. 6).

- Direction of Rotation: The gearing is precisely arranged so that:

- The two outer shafts of the upper row rotate outwardly from the center.

- The two lower shafts rotate in the same direction as the outer upper shaft just above them.

- Function (Circulation): This specific, intermeshing rotation directs the flow:

- Material is drawn down into the trough by the fingers of the two outer upper shafts.

- It is seized by the fingers of the two lower shafts and forced to the perforated bottom.

- If the crumbs are too coarse, they are carried around by the two lower shafts and thrown upward toward the central and outer shafts to be subjected to the crumbling action a second time.

- Result: The material is kept continually passing through the machine and has “no chance to escape the action” of the tearing fingers until it is thoroughly crushed.

Historical Significance and the Inventor

This 1895 patent is a significant contribution by Joseph Lee to the commercialization of food production, building upon his earlier work in dough mixing.

- Commercial Baking Efficiency: Bread crumbs are a staple for coatings, stuffings, and binding agents, and their production was a necessary, often manual, step in commercial baking and institutional kitchens (hotels, restaurants). Lee’s machine provided a dedicated, industrial-scale solution that was more effective than simple crushing or grinding, especially for non-stale bread.

- Solving the “New Bread” Problem: The patent explicitly addresses the difficulty of crumbing new (fresh) bread, which tends to roll and clump rather than crumble. The continuous, multi-shaft tearing and recirculation process was designed to overcome the stickiness of fresh bread, making the machine more versatile.

- The Inventor (Joseph Lee): Joseph Lee, an African-American inventor, is recognized for his focus on automating food preparation tasks. This machine, along with his earlier kneading machine and a later, simpler crumb-making apparatus, solidified his importance in the mechanical history of the baking industry.

Relation to Current Products

Lee’s machine utilizes a multi-roller, recirculating mechanism that is fundamental to modern food and material processing:

- Industrial Shredders/Grinders: The system of multiple counter-rotating shafts with intermeshing teeth (fingers) to tear material is the core design of modern industrial shredders, granulators, and grinders used in the food, plastic, and recycling industries. The counter-rotation ensures the material is continuously fed downward and torn apart, preventing jamming.

- Recirculation in Processing: The design that forces uncrushed material back up to the top for a second pass (recirculation) is a principle used in various forms of processing equipment, including ball mills and hammermills, to maximize the efficiency of reducing material to a uniform, specified fineness.