Bracket for Miners’ Lamps (Julius R. Watts, No. 493,137)

The patent describes an improved bracket for miners’ lamps designed to be expeditiously, conveniently, and securely attached to virtually any item of headwear, not just specially made mining caps. The primary object was to enable a miner to use an ordinary, or even an “old cast-off hat or cap,” with the same safety and convenience as a dedicated mining cap.

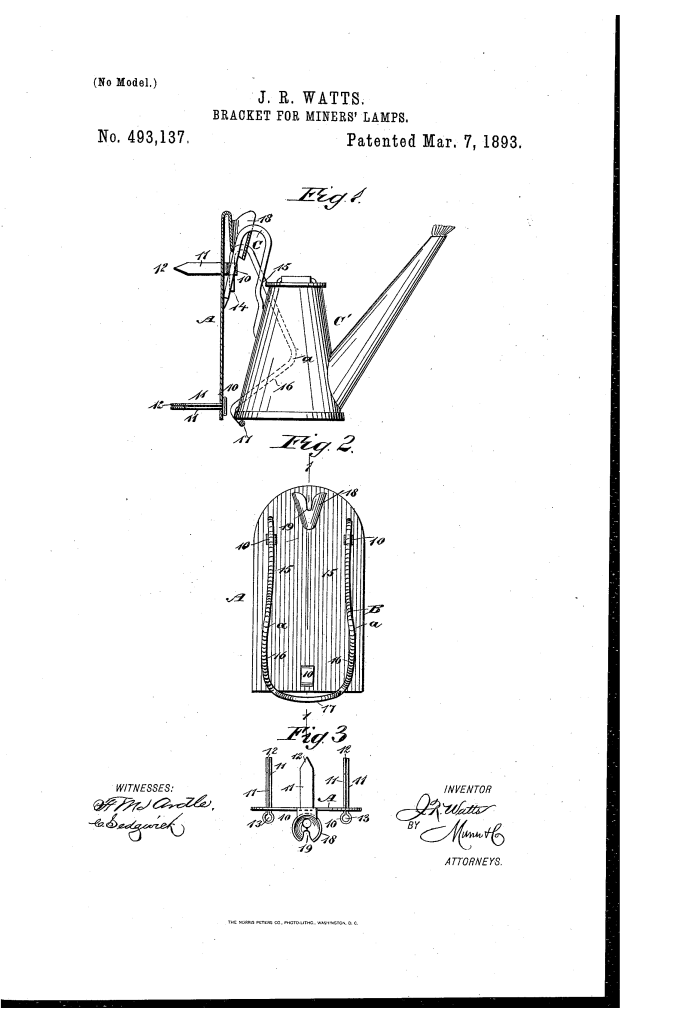

Invention and Mechanism

The bracket is an assembly of three main components: a back plate, a yoke frame, and unique fastening shanks.

- Back Plate (A) and Fastenings:

- The plate rests against the outside of the hat.

- Fastening is achieved using several pliable metal shanks (11), typically three (two at the top, one at the bottom).

- The shanks have pointed ends (12), allowing them to be easily pushed through the hat material.

- Once through, the shanks are bent in opposite directions against the inside surface of the hat, securing the bracket without special tools or a dedicated hole/grommet.

- Lamp Hook Keeper (18):

- A socket or keeper (18), shaped like an inverted conical frustum, is permanently located at the upper center of the plate (A).

- It has an open, flaring mouth at the top for easy lamp insertion (even without removing the hat).

- It features a downwardly-extending recess (19) to steady and guide the hook (C) of the miners’ lamp.

- Supporting Yoke (B) and Lamp Support:

- The yoke is made of a single piece of wire bent into a yoke form.

- Its upper ends have pins (14) that fit into socket heads (13) on the top fastening devices.

- The yoke’s members (15) curve downward and outward to create space between the lamp body and the back plate.

- At the advanced points (a), the yoke members engage the lamp’s body.

- The lower bow portion (17) is curved laterally outward and forms a rest for the bottom of the lamp, holding the lamp at a proper inclination and distance from the cap.

Historical Significance and the Inventor

The invention by Julius R. Watts of Springfield, Illinois, reflects a focus on practicality and accessibility in mining equipment during the late 19th century.

- Standardization vs. Practicality: Specialized miners’ caps, often stiff leather or canvas, were designed with a ready-made lamp-holding socket. However, Watts’s invention addressed the needs of miners who may have preferred to wear their own comfortable or cheaper headwear, or who simply did not have access to dedicated mining caps. This provided a practical, retrofittable safety solution for the average worker.

- Safety and Efficiency: The primary function of a miner’s lamp was safety—providing illumination in the darkness of the mine. By creating a bracket that could be “expeditiously, conveniently and securely attached,” Watts ensured that the crucial light source could be reliably mounted, which was vital for both safety and work efficiency.

- Simple Manufacturing: The construction is noted as being “exceedingly simple and economical.” This ease of manufacture using basic materials (pliable metal for shanks, bent wire for the yoke) meant the bracket could be produced cheaply and distributed widely, making it an accessible safety upgrade for miners across the country.

Relation to Current Items

Watts’s bracket embodies design principles that are still foundational to modern personal safety and mounting hardware:

- Universal Mounting: The bracket’s core idea—a simple, pliable mounting system to attach specialized equipment to a non-specialized item of clothing—is seen everywhere today in accessory clips and retrofit mounts. Examples include:

- Action Camera Mounts: Flexible adhesive or strap-based mounts that attach cameras to helmets, vehicles, or gear not originally designed for them.

- Safety Light Clips: Battery-powered LED lights with pliable clips (like the shanks) used to attach to clothing, backpacks, or caps for high visibility.

- Tool-less Attachment: The use of pointed, bendable shanks for quick, secure, and tool-less attachment is directly mirrored in modern staple-gun principles and temporary, high-strength fabric fasteners.

- Modular Lamp Holders: While modern mining uses electric headlamps attached to lightweight hard hats , the overall configuration—a rigid socket for quick insertion/removal (the keeper 18) combined with a support frame (the yoke B) that maintains the lamp’s angle—is the identical functional layout used in modern lamp brackets and headlamp mounts.