Bottle (Albert C. Richardson, No. 638,811)

The patent by Albert C. Richardson of South Frankfort, Michigan, describes a new and useful improvement in Bottles or analogous receptacles (Patent No. 638,811, 1899). The object is to provide a simple and comparatively inexpensive bottle with a stopper that can be adjusted to either fully close the neck or to partially open the same, allowing the contents to be poured out in small, controlled quantities.

Inventor Background: Albert C. Richardson

Albert C. Richardson was an African-American inventor known for practical household and service innovations, such as his Casket-Lowering Device (No. 529,311). This patent shows his focus on refining everyday consumer products. The invention addresses the common issue of uncontrolled pouring and spillage from traditional bottles, providing a solution for accurate dosing.

Invention and Mechanism

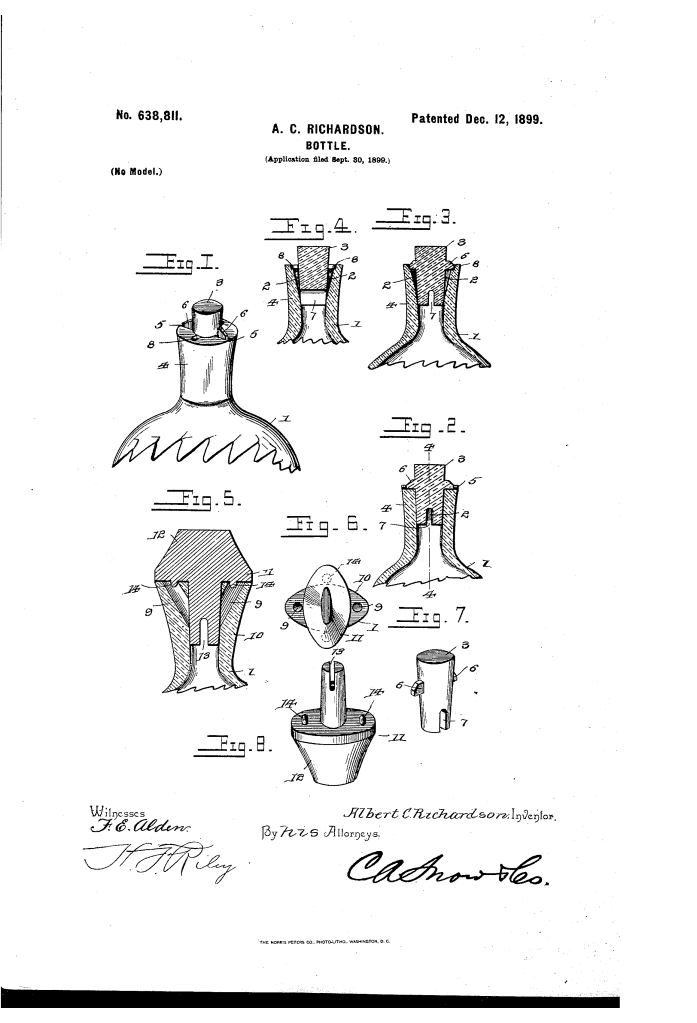

The bottle features internal channels and a rotating, bifurcated stopper that acts as a simple flow regulator and a secure lock.

1. Neck and Channels

- Bottle (1) Neck: The interior of the neck is provided with longitudinal grooves (2) at opposite sides, forming channels.

- Function: When opened, one channel serves as the pouring passage and the other serves as the vent (affording communication between the interior and exterior of the bottle).

2. The Adjustable Stopper (Key Innovation)

- Stopper (3): A stopper that fits into the neck.

- Slot/Bifurcation (7): The stopper is provided with a slot or bifurcation (7) extending upward from its lower end, forming an opening across the stopper.

- Rotation for Control:

- Pouring Position (Fig. 2): The stopper is rotated so that its slot (7) registers with the two channels (2). This connects the channels, allowing the contents to flow out one channel while air enters through the other (providing a smooth, controlled flow).

- Closed Position (Fig. 3): The stopper is rotated so that the solid body of the stopper covers and moves the slot (7) out of register with the channels (2). The lower end of the stopper extends below the channels, closing the mouth and preventing escape of contents, even when inverted.

- Fine Control: The small size of the flow is such that the user can apply a finger to the vent channel to control or stop the flow entirely, allowing contents to be discharged drop by drop.

3. Locking Mechanism

- Lugs/Projections (6): The stopper (3) has laterally-extending lugs (6).

- Notches (5 and 8): The bottle neck has corresponding notches or recesses (5 and 8).

- Function: The lugs engage the notches (5) when the bottle is closed (slot 7 out of register) to lock the stopper against accidental rotation. They engage the notches (8) when the bottle is open to lock the stopper in the pouring position.

Concepts Influenced by This Invention

Richardson’s bottle design influenced subsequent packaging and dispensing mechanisms by pioneering the rotational valve principle for controlled, small-quantity pouring.

- Rotational Metering/Dispensing: The core concept of using a rotating element (Stopper 3) with an opening (Slot 7) to align with fixed channels (2) in the body to control fluid flow is the basis for:

- Pour-Spout Dispensers: Modern containers for oils, syrups, or cleaning agents that use a rotating cap to align openings for pouring and venting.

- Flow Regulators: Simple valve-gate mechanisms in consumer and industrial containers where rotation dictates the open/closed state.

- Integrated Venting: The design’s simultaneous use of two channels (one for pour, one for vent) to ensure a smooth, glugging-free flow influenced the design of modern fluid container spouts and caps.

- Finger-Tip Flow Control: The ability to achieve fine, drop-by-drop dispensing by manually covering the vent channel influenced the design of various specialized dosing bottles for medicines, flavorings, and chemicals.