Burner for Water-Heaters (Isaac E. Reis, No. 638,143)

The patent by Isaac E. Reis of St. Louis, Missouri, describes an improved Burner for Water-Heaters (Patent No. 638,143, 1899), designed for use with gas or other vapor fuels. The invention focuses on creating a durable, cheaply manufactured burner assembly that efficiently heats a water coil, minimizing heat loss and providing structural support for the entire heater casing.

Inventor Background: Isaac E. Reis

Isaac E. Reis was an inventor specializing in thermal and heating equipment, contributing to the growing market for gas-powered domestic and commercial appliances. His work focused on optimizing the combustion and heat transfer efficiency of gas burners, which were rapidly replacing solid fuels in many urban settings at the turn of the 20th century.

Invention and Mechanism

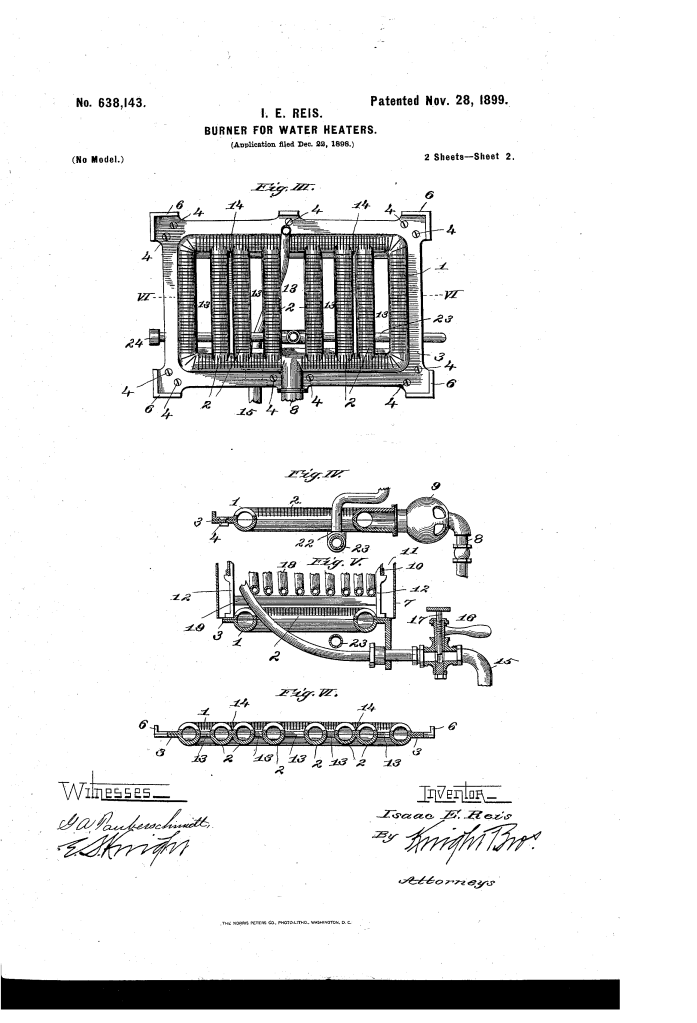

The burner is a two-piece, cast-metal grid designed for easy manufacturing and efficient flame distribution under a water coil.

1. Burner Construction (Key Innovation: Two-Piece Casting)

- Shape: The burner (1) is made in the form of an outside surrounding tube (preferably rectangular) and internal cross tubes (2) that connect the sides of the surrounding tube.

- Manufacturing: The burner is produced in two separate castings: the lower halves of all tubes in one casting, and the upper halves of all tubes in another casting.

- Assembly: The two castings are fitted together and secured by flanges (3) and screws (4).

- Function: This two-part design makes the burner assembly cheaply produced and highly durable, simplifying the manufacturing process for complex shapes.

2. Structural and Flame Efficiency

- Airflow and Strength: The cross-tubes (2) are separated by spaces (13) for air, except for specific tubes (14) near the ends that are joined together (no space).

- Function: The joined tubes (14) firmly bind and hold the two castings together, enhancing the structural integrity of the burner.

- Base/Support: The secured flanges (3) form the base of the stove and rest upon supporting legs. The upper flange has an upturned edge (6) to receive and support the outer casing or jacket (7) of the water heater.

- Coil Placement: A water coil (18) is located within the inner casing (10) above the burner. Gas escapes through slots/slits in the upper half of the tubes, directing the flame upward to the coil.

3. Water Supply Control

- Coil Support: The coil (18) is supported on cross-pieces (19) secured to standards (12) that rise from the burner base.

- Regulating Faucet: The water supply pipe (15) has a faucet (16) with a regulating plug or valve (17) that can be screwed up or down, allowing the flow of water to the coil to be regulated to a nicety.

Concepts Influenced by This Invention

Reis’s burner influenced subsequent thermal and gas appliance design by establishing principles for cast-component modularity and integrated structural support.

- Two-Part Cast Component Design: The most significant influence is the strategy of designing a complex, hollow industrial component (the burner grid) as two simpler castings (upper and lower halves) joined by bolts and flanges. This technique influenced the design of engine manifolds, industrial housings, and modular pump components by reducing complexity in the mold, simplifying core placement, and easing manufacturing.

- Integrated Support Structure: The design’s use of the burner housing and its flanges (3, 6) to serve as the entire structural base and support jacket for the water coil and casing influenced the engineering of modern compact appliances where the heating element assembly is inherently structural.

- Targeted Heat Application: The construction that ensures flames escape from slots in the upper half of the tubes and are directed closely under the water coil reinforces the principle of maximizing direct heat transfer and minimizing heat escape, crucial for energy efficiency in gas appliances.

- Fine Flow Regulation: The inclusion of a faucet with a regulating screw/plug (17) to precisely adjust the water flow influenced the design of industrial and domestic fluid control systems that require accurate setting of flow rate rather than simple ON/OFF control.