Band-Twister (William Douglass, No. 789,120)

The patent by William Douglass of Phillipsburg, Kansas, describes a Band-Twister (Patent No. 789,120, 1905). This invention is designed to twist loose strands or fibers into a band for tying bundles of grain, and is a key automated subsystem of a larger self-binding harvester.

Inventor Background: William Douglass

William Douglass was an inventor focused on large-scale agricultural machinery. His work on the self-binding harvester addressed the critical need for reliable, mechanized harvest and tying to maximize efficiency and production on large farms.

Invention and Mechanism (Simplified)

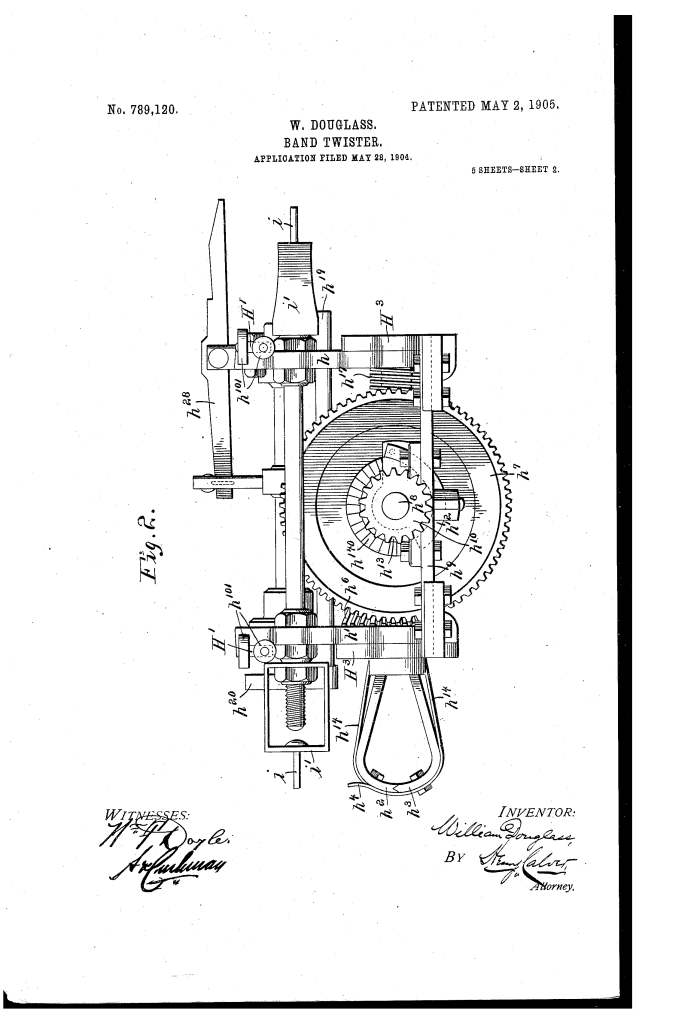

The device is a carriage that moves back and forth on tracks, using the motion itself to power a twisting head that automatically grabs, spins, and releases the material.

- Carriage and Drive: The core mechanism is the twister-carriage, which slides on tracks. Its power comes from a fixed rack attached to the main machine frame. A gear on the carriage meshes with this rack.

- Function: As the carriage slides back and forth (translational motion), the gear travels along the rack, causing the attached shaft to rotate rapidly (rotary motion). This converts the simple back-and-forth movement into the spinning motion needed for twisting. A ratchet ensures the spinning only happens on the outward (twisting) stroke.

- Automatic Grab, Twist, and Release (Self-Timing): The entire process is controlled by the carriage hitting fixed external stops.

- Jaws: The device uses spring-closed jaws mounted on the rotating shaft. A sliding cone on the shaft normally holds these jaws open.

- Closing (Grab): As the carriage moves forward, an arm hits a stationary stop. This contact pushes the cone backward, releasing the jaws’ springs, which snap shut to grab the straw band.

- Twisting: The carriage moves outward, and the gear spins the jaws, twisting the band.

- Opening (Release): When the carriage reaches its limit, another arm hits a second fixed stop. This action releases the lock on the cone, allowing the cone’s internal spring to push it forward, forcing the jaws open and releasing the finished band.

Concepts Influenced by This Invention

Douglass’s band-twister influenced subsequent industrial and packaging machinery by pioneering integrated motion conversion and self-timing systems for complex sequential tasks.

- Translational-to-Rotary Conversion: The core concept of using a fixed rack and a mobile pinion to generate the necessary rotary twisting motion from the main machine’s linear carriage movement is a highly efficient and durable principle. This influenced the design of various mechanical actuators and textile machines that need to synchronize linear and rotational motion.

- Automated Sequential Kinematics (Twisting): The entire system, using fixed stops to control a spring-loaded/cone-driven mechanism, is a masterclass in complex sequential automation. This influenced the design of all subsequent tying, wrapping, and knotting machinery in packaging, agriculture, and textile industries.

- Mechanical Self-Timing: The device is entirely self-timed by the physical interaction between the moving carriage and fixed external stops at the ends of its travel. This influenced the design of robust, low-maintenance industrial machines that use mechanical limit switches and contact arms to govern the start and end of high-force cycles.

- Jaw Locking and Release Mechanism: The use of an internal sliding cone to control the opening/closing of spring-tensioned jaws influenced the design of specialized grippers and clamping systems in automation and packaging.