Baling-Press (Robert H. Gray, No. 525,203)

The patent by Robert H. Gray of Lexington, Kentucky, describes an improved Baling-Press designed for compressing cotton, hay, and similar products into compact, easily transportable form. The primary object is to create a simple, compact, and continuously operating press, preferably made of light sheet metal for easy transport.

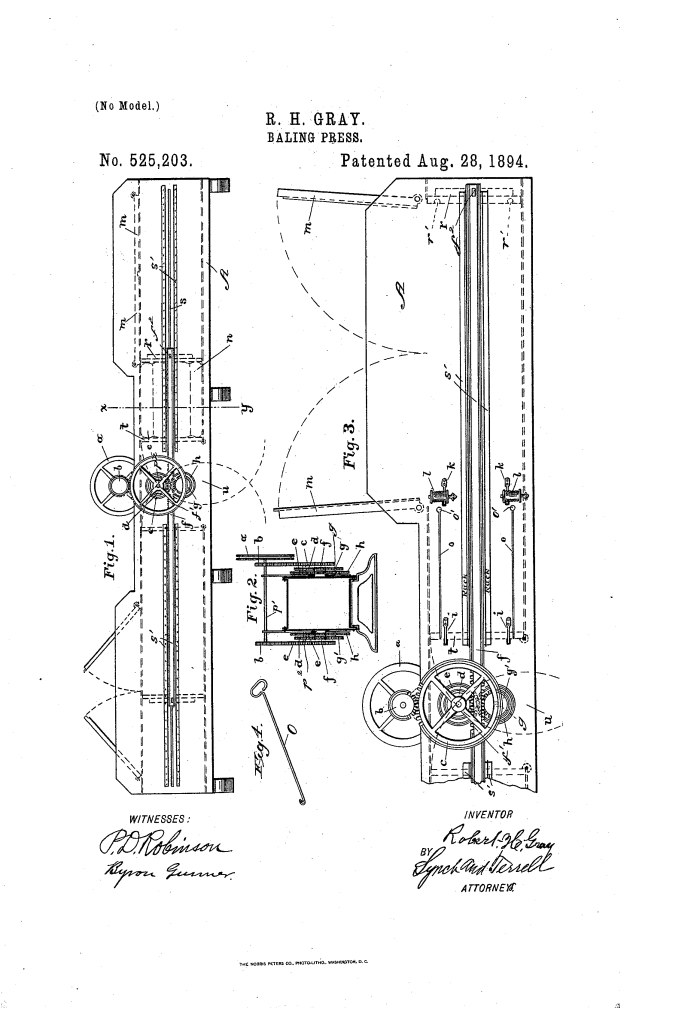

Invention and Mechanism

The press is a double-action, continuously operating machine that uses two opposing rack-and-pinion driven heads working alternately.

1. Structure and Dual-Action Compression

- Press Box (A): The main body, preferably constructed of sheet metal for lightness and compactness. It has two compression chambers (one at each end) and a central delivery opening in the bottom.

- Rack Bars (f): Two rack bars, one on each side of the press box, mounted in guideways (s) along slots (s) in the sides of the box. The rack teeth (f′) are on both the upper and under edges.

- Pressure Heads (r): Two heads, secured to the ends of the rack bars (f), sized to nearly fill the chambers.

- Function: The pressure heads move alternately: as one head moves in to compress material in one chamber, the other head moves out to its starting position, ready for the next load in the opposite chamber.

2. Driving and Gearing

- Power Source: Power is applied to a driving pulley (a) on a central horizontal shaft (p′).

- Gear Train: A complex train of gears links the central shaft to the rack bars:

- Shaft (p′) drives gears (c,c) on a second shaft (p).

- Shaft (p) drives a third shaft (g) via gears (e,e) and (h,h).

- Shaft (p) has pinions (d,d) engaging the upper teeth (f′) of the rack bars.

- Shaft (g) has pinions (g′,g′) engaging the under teeth (f′) of the rack bars.

- Function: This elaborate gearing ensures that continuous, synchronized, and powerful reciprocal motion is imparted to the rack bars and pressure heads.

3. Tying and Ejection

- Pivoted Heads (t,t′): The inner ends of the two compression chambers are closed by swinging heads, which are pivoted to the sides of the box.

- Function: These heads swing downward through the central opening in the bottom of the box for ejection of the finished bale. They are held upright by spring catches (i,i′).

- Binding Wires: Wire-carrying spools (l,l) are mounted on the sides of the box. Wires pass through slots (o,o) and small holes (o′,o′), stretching across the compression chamber just inside the feed opening.

- Tying: The pressure head (r) has slots or recesses (o′′) on its inner face that register with the holes (o′,o′) when the bale is fully compressed. A hooked tool (O) is passed through these holes and recesses to pull the binding wires through, allowing the bale to be tied.

- Retention: Spring catches (k,k′) snap behind the pressure head (r) when it reaches its inner position, holding the bale compressed while it is being tied, thus relieving the strain on the gearing and power shaft.

- Ejection: Once the bale is tied, the pivoted head (t or t′) is released, and the continued motion of the opposing pressure head forces the finished bale down and out through the central bottom opening.

Historical Significance and the Inventor

Robert H. Gray’s 1894 patent is a significant refinement in the mechanization of agriculture and commodity transport in the late 19th century.

- Commodity Compression: The need to bale products like cotton and hay was paramount for cost-effective transportation. Loose material occupied vastly more space, leading to high shipping costs. Presses like Gray’s were essential components of the agricultural supply chain.

- Continuous Operation: The dual-action design was the key innovation. Unlike single-action presses that required the mechanism to reverse and restart for every bale, Gray’s press provided continuous, alternate operation. As one bale was being compressed, the other side was automatically reset and ready for loading, greatly increasing the throughput and efficiency of the operation.

- Design for Transport: The preference for sheet metal construction and the ability to pack the press into a “very small compass” for transportation reflects the logistical demands of the era, where agricultural machinery often had to be moved between farms or fields.

- The Inventor (Robert H. Gray): Gray, residing in Lexington, Kentucky, was working in a region heavily focused on tobacco and horse farming (hay), making the improvement of baling machinery a direct economic necessity for the local economy.

Relation to Current Items

Gray’s Baling-Press contains design concepts still used in modern industrial machinery:

- Continuous Dual-Action Presses: The principle of alternate, simultaneous operation (as one side works, the other resets) is the foundational design for modern high-density horizontal balers used in recycling centers and commodity processing plants to handle materials like cardboard, plastic, and scrap metal.

- Rack-and-Pinion Drive: The use of rack-and-pinion gearing for linear motion is a standard, robust solution in heavy machinery where large forces and precise, controlled movement are needed, such as in CNC machines and large industrial presses.

- Automated Tying Precursors: The method of prepositioning the binding wires (l,l) and using aligning slots (o′,o′) on the pressure head is the precursor to modern automatic baling knotters and tyer mechanisms. Today’s large agricultural balers automatically wrap, knot, and cut the twine/wire while the bale is compressed, eliminating the need for a manual tool and leveraging the same principle of wire prepositioning.

- Over-Center Locking (Retention): The spring catches (k,k′) that hold the compression head and relieve strain on the gearing are an application of the over-center lock or mechanical stop principle, ensuring the applied force is held by a static mechanical feature, freeing the prime mover (the gears) from continuous load.