The patent by Charles T. Christmas of Riverton, Mississippi, describes a new and useful Improvement in Bale-Band Tighteners (Patent No. 231,273, 1880). The invention provides a specialized, hand-operated lever tool for drawing a band tightly around a compressed bale to minimize expansion and distribute pressure evenly.

Inventor Background: Charles T. Christmas

Charles T. Christmas was an inventor from Mississippi who focused on practical mechanical solutions for both domestic and agricultural efficiency. He is also the inventor of the Hand-Power Attachment for Sewing-Machines (No. 226,492). His work on the Bale-Band Tightener directly addresses the needs of cotton and hay farmers in the South, where efficient baling was critical for crop transport and sale.

Invention and Mechanism

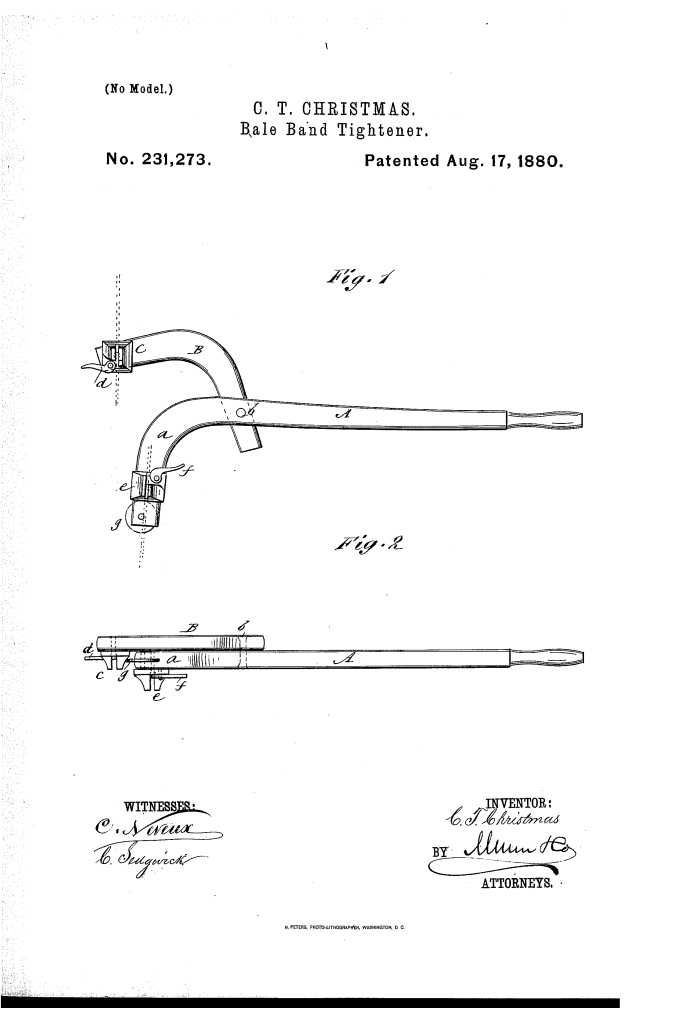

The tightener is a two-armed, cross-pivoted lever that uses cam-locks and mechanical advantage to apply high tension to the band.

1. Lever and Pivot System

- Lever (A): The main lever, curved at the end ($a$).

- Arm (B): A curved arm cross-pivoted to the lever (A) near its bent end ($a$) by a pin ($b$).

- Function: This cross-pivot creates a toggle or lever action between the two arms, allowing the operator to generate significant force to draw the two ends of the bale band together.

2. Band Clamping and Locking (Key Innovation)

- Slotted Blocks ($c$ and $e$): Two slotted blocks are fitted to the ends of the arms (A and B).

- Cam-Levers ($d$ and $f$): Each slotted block is fitted with a cam-lever ($d$ and $f$) hung in a recess.

- Function: The two ends of the bale band are inserted into the slots and clamped securely by turning the cam-levers. This cam-locking mechanism provides a powerful, quick-release grip on the flat metal band.

- Swivel: The block ($c$) on arm B is attached by a screw-pin, allowing it to swivel on the arm.

3. Operation and Finish

- Tensioning: The band is clamped onto both blocks. Pressing down on the outer end of the main lever (A) draws the two ends together. The operator holds the tension with one hand while securing the tie ends (button or buckle) with the other.

- Friction-Roller ($g$): A friction-roller is fitted at the extreme end of lever A.

- Function: This roller permits the end of the lever to slide over the bale readily without catching, ensuring smooth operation as the final tension is applied.

Concepts Influenced by This Invention

Christmas’s tightener influenced subsequent mechanical tools by pioneering the use of lever-actuated toggles combined with cam-locks for high-force fastening.

- Lever-Toggle Tensioning: The core concept of using a cross-pivoted main lever (A, B) to convert user hand-force into high tensile force over a short distance influenced the design of:

- Load Binders: Devices used to secure cargo on flatbeds, which rely on compound leverage to tighten chains or straps.

- Tensioning Tools: Manual tools used for securing strapping (banding) and cables, which use mechanical advantage to overcome the resistance of the strap material.

- Cam-Lever Clamping: The use of cam-levers (d, f) to provide a quick, powerful, and temporary lock on the flat bands is a principle used today in quick-release clamps, bench vises, and industrial fixtures , where turning a lever quickly applies immense clamping pressure.

- Integrated Glide Surfaces: The inclusion of the friction-roller to ensure smooth sliding over the work surface while force is being applied influenced the design of tools and fixtures intended for high-force applications over sensitive or rough materials (e.g., floor installation tools, cargo handling systems).