Automatic Stopping and Releasing Device for Mine Cars (George M. Johnson, No. 1,249,106)

The patent by George M. Johnson of McDonald, Pennsylvania, describes an Automatic Stopping and Releasing Device for Mine Cars (Patent No. 1,249,106, 1917). This invention is a critical safety and efficiency mechanism for mining operations, designed to manage the movement of cars onto and off a mine cage (elevator). Johnson’s primary goal was to automate the locking and unlocking of mine cars using the weight of the cars themselves, while ensuring that the mechanical components would not be damaged when the elevator ascended.

Inventor Background: George M. Johnson

George M. Johnson was an African American inventor and engineer working in the coal mining regions of Pennsylvania during the early 20th century. His work focused on the rugged, heavy-duty machinery required for coal extraction. Mining was a high-stakes environment where mechanical failure could lead to catastrophic accidents or costly delays. Johnson’s invention—specifically the “shiftable” section of the plunger—demonstrated his ability to solve real-world industrial problems with elegant, durable engineering solutions.

Key Mechanical Components & Functions

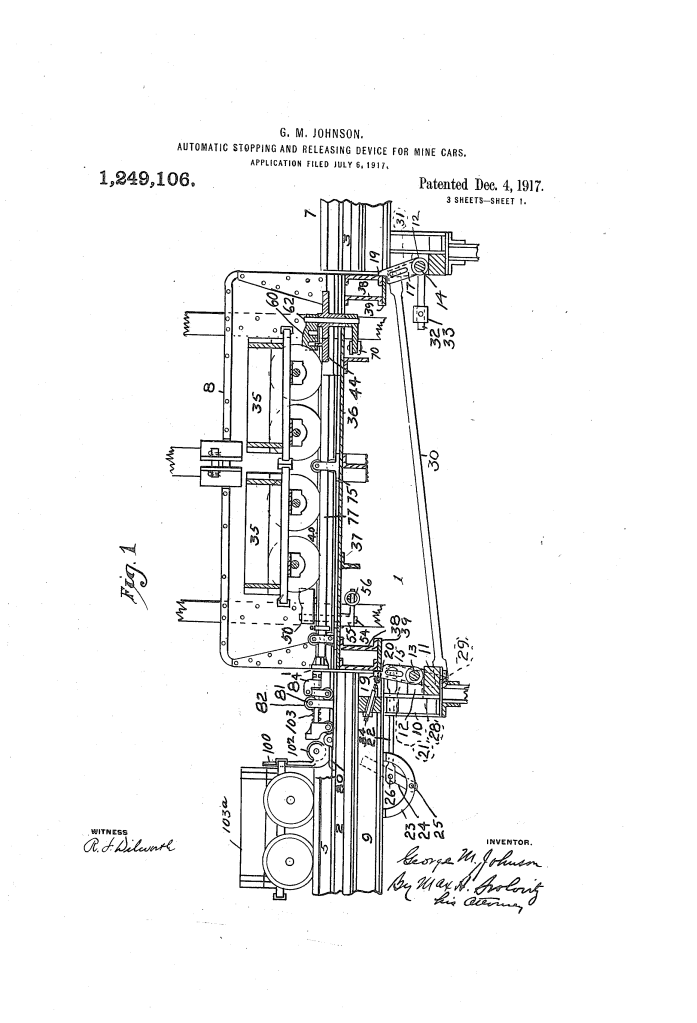

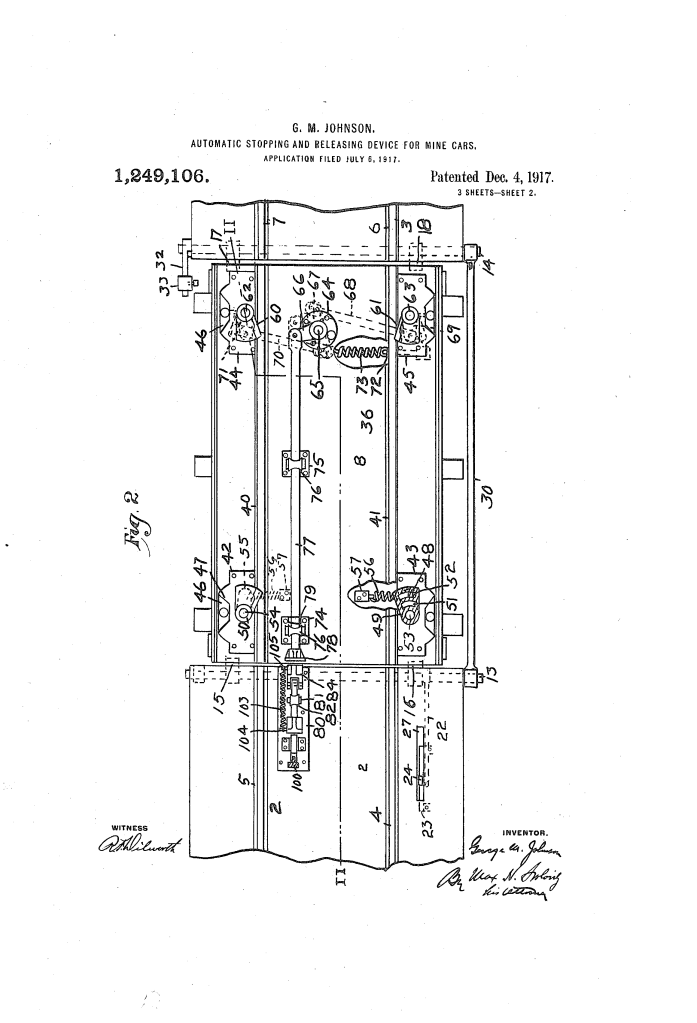

The system is a complex assembly of track-mounted stops, push rods, and a specialized plunger mechanism.

1. The Landers and Cage Support (15, 17)

- Lander Mechanism: When the mine cage (8) reaches a landing, a series of upwardly extending landers (15, 17) project toward the shaft to support it.

- Support Shoulders: These landers feature a shoulder (19) and ledge (20) that act as a seat for the cage, ensuring the track on the cage floor (36) aligns perfectly with the tracks on the ground.

2. The Stop-Block System (49, 60)

To prevent cars from rolling off the cage, Johnson used two sets of quadrant-shaped blocks:

- Rearward Stop Blocks (49, 50): These are spring-controlled and automatically pushed aside by the wheels of a car entering the cage, then snap back to lock it from behind.

- Forward Stop Blocks (60, 61): These remain locked in front of the car until the shifting mechanism is triggered.

3. The Actuating Push Rod (77)

- Anti-Friction Rollers (76): Beneath the cage floor, an elongated push rod (77) moves longitudinally.

- Function: To overcome the heavy friction inherent in industrial mining, Johnson mounted this rod on anti-friction rollers (76). When the rod is pushed forward, it rotates a series of crank shafts (62, 63) to pull the forward stop blocks away from the rails, releasing the car.

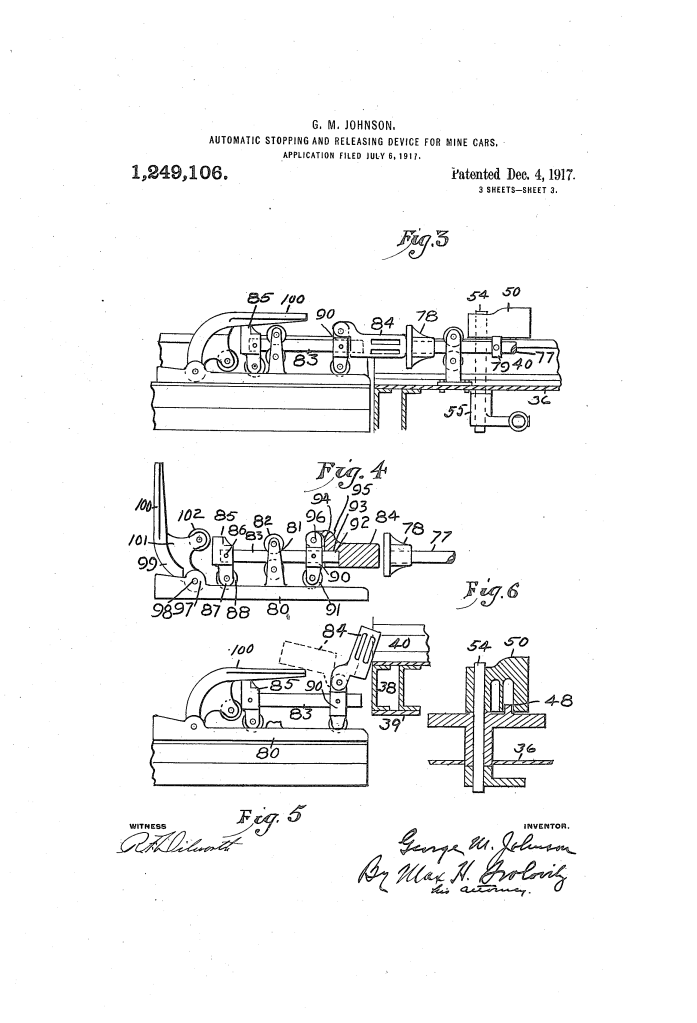

4. The Sectional Safety Plunger (83, 84) (Key Innovation)

The most significant improvement in this patent is the plunger that pushes the rod.

- Sectional Design: The plunger consists of a main section (83) and a larger abutment section (84).

- The Pivot (96): The abutment section is pivotally connected to the main section.

- Function: Normally, the plunger acts as a solid rod to release the cars. However, if the mine cage ascends while the plunger is still extended, the abutment section (84) can simply “swing back” or tilt out of the way. This prevents the ascending cage from smashing into the machinery and causing a mechanical breakdown.

Improvements Over Previous Mining Safety Devices

| Feature | Standard Mine Car Stops | Johnson’s Device |

| Safety on Ascent | Rigid plungers often broke if the cage moved unexpectedly. | Sectional plunger (84) pivots out of the way to avoid damage. |

| Friction Management | Heavy grease and manual effort. | Integrated anti-friction rollers (76) for smooth, uniform travel. |

| Reset Logic | Relied on heavy, dangerous counter-weights. | Used coil springs (73, 103) to restore the system to neutral. |

| Locking while Loaded | Required separate manual locks. | Allows cars to be locked on the cage even when supported by landers. |

Significance to Industrial Engineering

George M. Johnson’s device influenced the development of automated material handling and fail-safe mechanical logic.

- Fail-Safe Design: The “swing-away” plunger is a classic example of yielding architecture, where a machine is designed to give way under unintended stress rather than break. This principle is still used in modern safety gates and industrial robotics.

- Modular Automation: By using the weight of the car to depress a lever (100) which then actuates the plunger, Johnson utilized passive sensing—using the energy of the workload to control the machine’s safety state.

- Industrial Durability: Johnson specifically addressed the issue of “clogging” caused by coal dust and debris. His quadrant-shaped blocks and covered runways (47) were engineered for the harsh, dirty reality of 1917 mining conditions.