🍽️ Automatic Serving System (James Doyle, No. 1,019,137)

The patent by James Doyle of Pittsburgh, Pennsylvania, describes an Automatic Serving System (Patent No. 1,019,137, 1912). The invention is an elaborate, electromechanical restaurant infrastructure designed to entirely eliminate the necessity of waiters. The system automates the entire dining experience, from the transmission of written orders to the kitchen to the overhead delivery of food directly onto the customer’s table, aiming to reduce noise, confusion, and labor costs.

Inventor Background: James Doyle

James Doyle was an African-American inventor based in Pittsburgh during a time of significant industrial innovation. His serving system represents one of the most complex and forward-thinking patents of the early 20th century. By designing a fully integrated “smart” restaurant—incorporating elements of pneumatic-style ordering, motorized transit, and automated descent mechanisms—Doyle anticipated the modern concept of “contactless” service and automated dining (later popularized by the “Automat”). His work demonstrates a sophisticated mastery of electrical circuitry, gearing, and logistics.

Invention and Mechanism (Simplified)

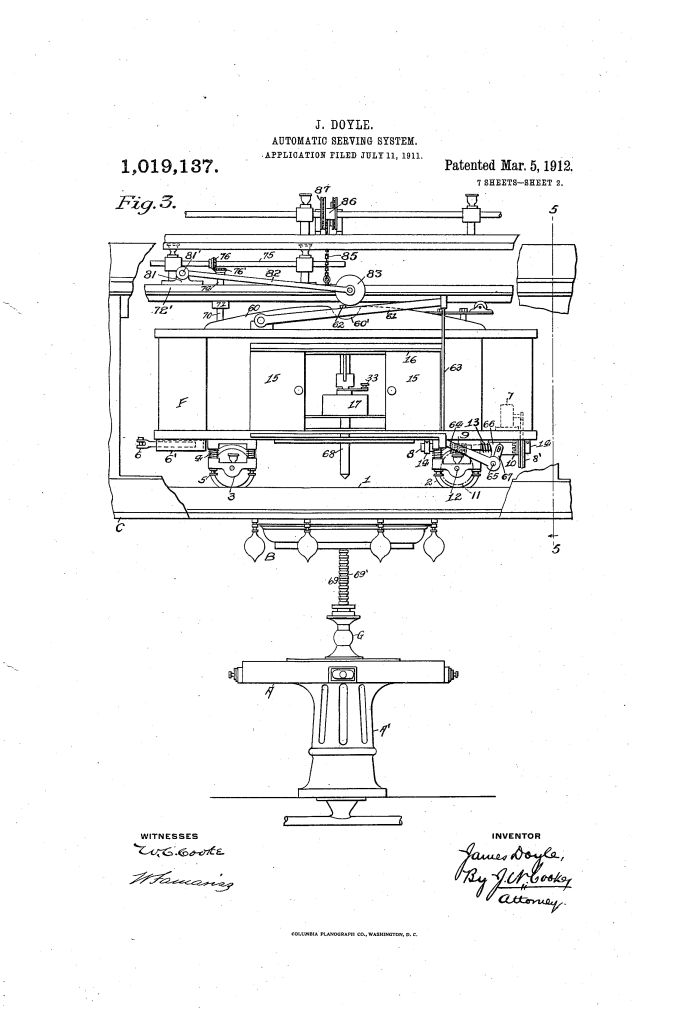

The system is comprised of three primary subsystems: the Order Transmitter, the Overhead Railway, and the Automatic Server.

1. The Ordering System (Table to Kitchen)

- Hollow Balls (45) and Drawer (44): Each table (A) has a drawer containing hollow balls. The guest checks their food choices on a menu, places the slip inside a ball, and drops it into a passageway (46).

- Pneumatic/Gravity Tube (47): The ball rolls through an inclined tube to the kitchen.

- Elevator Chain (49): In the kitchen, a motorized chain picks up the balls and delivers them to the chef’s table (D).

2. The Overhead Railway and Motorized Cars

- Overhead Cabinet (C) and Tracks (1): A cabinet containing rails runs from the kitchen above the rows of tables.

- Motorized Cars (F): Electric cars, powered by a motor (7) and trolley rods (58), carry the food from the kitchen into the dining room.

- Braking and Stopping (Key Innovation): Above each table, a set of levers (82) can be lowered. As the car approaches, pulleys on these levers engage inclined plates (60) on top of the car. This slows the car and trips a clutch (10), stopping it precisely above the guest’s table.

3. The Automatic Server (Car to Table)

- Sliding Doors (92): Once the car stops, the bottom of the overhead cabinet automatically opens via a rack-and-pinion (102) mechanism.

- Winding Chains (43) and Server (17/G): A vertical shaft (70) in the car begins to rotate, unspooling chains that lower a tray (server G) through the cabinet doors and onto the table.

- Safety Notches (69): A central rod with notches guides the tray down. If a chain breaks, spring-loaded pins (41) snap into the notches to prevent the food from falling and spilling.

Concepts Influenced by This Invention

Doyle’s Automatic Serving System influenced the evolution of automated service and industrial material handling.

- Contactless Service and Automation: Doyle provided a blueprint for the automated restaurant, a concept that flourished in mid-century Automats and modern “conveyor belt” sushi restaurants.

- Precision Overhead Delivery: The use of an overhead gantry system to deliver delicate items (food) while maximizing floor space for customers influenced industrial warehouse automation and “pick-and-place” robotics.

- Remote Mechanical Actuation: The centralized operating board (103) in the kitchen, which used friction clutches and switches to control distant mechanical actions (opening doors, lowering trays), is a direct precursor to modern Programmable Logic Controllers (PLCs).

- Fail-Safe Gravity Braking: The safety mechanism using notched guide rods to catch falling loads became a standard feature in elevator design and industrial hoists.