Automatic Railway-Car Door (Walter N. McClennan, No. 1,333,430)

The patent by Walter N. McClennan of Brooklyn, New York, describes an Automatic Railway-Car Door (Patent No. 1,333,430, 1920). This invention represents a major leap in transit engineering, designed specifically for the high-volume environments of subways and elevated lines. Unlike previous door systems that relied on purely manual or semi-automated operation, McClennan’s design was a fully integrated safety system. It automated the opening of doors upon arrival at a station, provided mechanical gap-bridging to prevent accidents, and introduced safety fenders to protect passengers’ feet from moving parts.

Inventor Background: Walter N. McClennan

Walter N. McClennan was an African American inventor and mechanic who lived and worked in Brooklyn during the rapid expansion of the New York City Subway and Elevated systems. His 1920 patent addressed the specific dangers of “gap” accidents and the inefficiencies of manual door operation that plagued early 20th-century transit. By combining pneumatic power with mechanical ramp-sensing, McClennan engineered a system that removed human error from the most dangerous part of the commute.

Key Mechanical Components & Functions

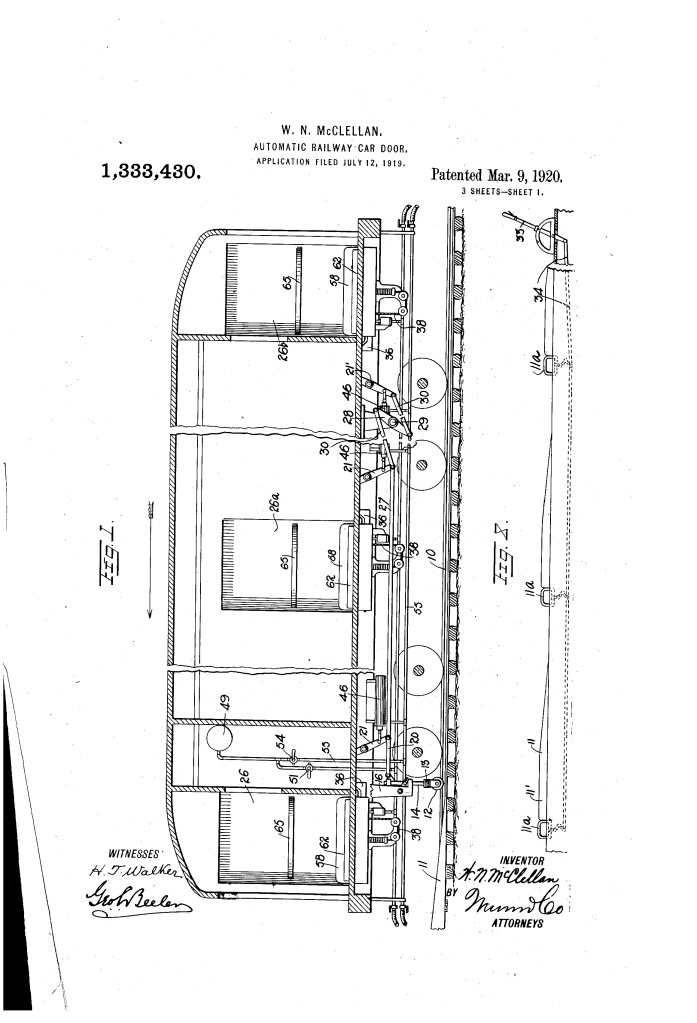

The system is a complex interplay between track-side hardware and on-car mechanical linkages.

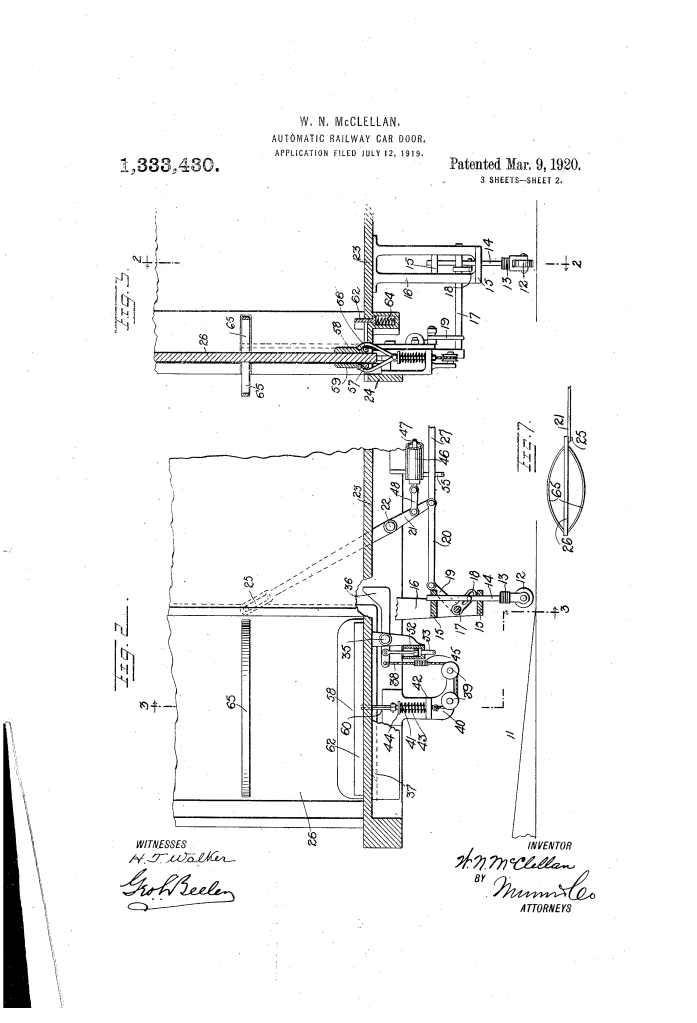

1. The Track-Side Ramp and Shoe (11, 12, 14)

- The Ramp (11): Located along the tracks at the station is a metal ramp (11) with a gradual rise.

- The Roller Shoe (12): Beneath the car is a roller (12) or “shoe” connected to a vertical plunger (14).

- Function: As the car enters the station, the ramp physically lifts the roller shoe. This upward motion is the primary energy source that triggers the doors to open, ensuring they only open when the car is perfectly aligned with the station platform.

2. The Bell Crank and Door Lever (18, 21)

- Translation of Motion: The lift of the plunger (14) rotates a bell crank (18).

- Lever Linkage: This motion is transferred through a link (20) to a door actuating lever (21).

- Function: The lever swings on a pivot (22) and, via a pin-and-slot connection (25), slides the door (26) open. This creates a “positive” opening action that is physically synchronized with the car’s position on the track.

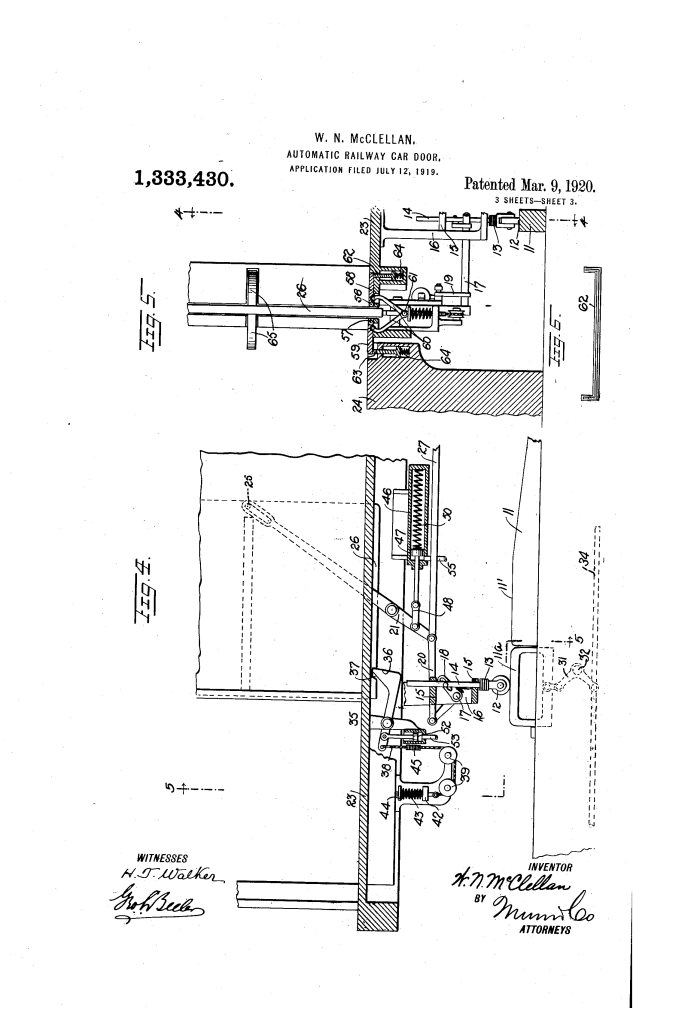

3. The Gap-Bridging System (58, 59) (Key Innovation)

Subway platforms often have a dangerous “gap” between the car and the platform. McClennan solved this with moving bridge members.

- Bridge Members (58, 59): These are flat plates pivoted at the floor level.

- Automatic Deployment: They are connected to the door mechanism by links (60).

- Action: As the door slides open, it automatically forces these bridge plates to drop from a vertical “storage” position to a horizontal “bridging” position. This creates a solid surface for passengers to walk across, eliminating the risk of falling into the gap.

4. Safety Fenders and Guard Rails (62, 63, 65)

- Fenders (62, 63): These are spring-loaded vertical guards that rise across the floor.

- Function: They prevent a passenger’s foot from being trapped underneath the bridging plates as they swing down.

- Guard Rails (65): The doors themselves carry bowed guard rails (65).

- Function: As the door slides open or closed, these rails gently “nudge” passengers away from the moving door’s path, preventing clothes or limbs from being snagged.

5. The Pneumatic Reset (46, 52)

- Closing Control: While opening is triggered by the ramp, closing is handled by a compressed air motor (46).

- Operator Override: The motorman uses a trip valve (51) to actuate a trip motor (52) that releases the mechanical catch (36) holding the door open. Once released, the pneumatic piston (47) slides the door shut.

Improvements Over Existing Transit Systems

| Feature | Standard Subway Doors (c. 1915) | McClennan’s Automatic System |

| Opening Trigger | Manual by a conductor between cars. | Automatic via track-side ramp (Positive Alignment). |

| Platform Safety | Open gaps; constant risk of falling. | Integrated bridging plates (58, 59) close the gap. |

| Crush Prevention | Heavy doors could slam on passengers. | Bowed guard rails (65) and spring-fenders protect limbs. |

| Centralized Control | Required a conductor for every two doors. | Motorman can control and lock all doors from the cab. |

Significance to Transit Engineering

Walter N. McClennan’s automatic door influenced the design of modern rapid transit and platform-edge safety.

- The Positive Opening Principle: The idea that a door should only be “allowed” to open by a physical interaction with the station (the ramp) is a precursor to modern Door-Track Interlocks and Platform Screen Doors (PSDs).

- Automatic Gap Management: His bridging plates were an early version of the mechanical gap fillers used today in curved-platform stations (like London’s Underground or NYC’s Union Square).

- Passenger Flow Logic: By automating the doors to open coincidentally with the stop, McClennan reduced “dwell time,” allowing trains to move more people more efficiently through a crowded city.

- Fail-Safe Locking: The use of a notched catch to mechanically lock the door open ensured that a failure in air pressure wouldn’t cause a door to slam shut on boarding passengers.