The patent by William H. Jackson of Indianapolis, Indiana, describes an Automatic Locking Switch (Patent No. 609,436, 1898). This invention is an improvement on his prior switch designs, focusing on a more complex safety sequence: the switch must be locked open to the siding while a train is using it, and then automatically released and returned to the main track only after the entire train has passed.

Inventor Background: William H. Jackson

William H. Jackson was an inventor residing in Indianapolis, Indiana, specializing in railway safety and mechanical automation. His continuous work in the late 19th century addressed the high incidence of accidents and derailments caused by switches being left in the wrong position. His designs are characterized by robust, fail-safe mechanical solutions.

Invention and Mechanism

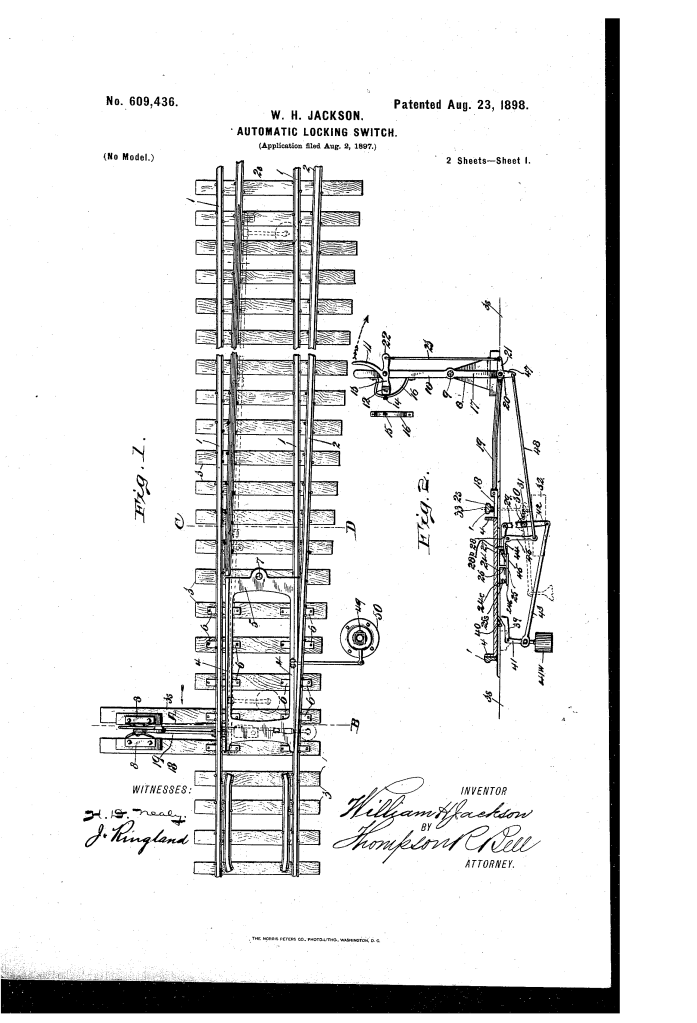

The switch uses a weight-and-shaft system combined with a complex, track-side trip rail that controls the locking sequence based on the presence of train wheels.

1. Switch Structure and Control

- Switch-Rail Plate (5): A plate pivotally secured to the track, carrying the switch-rails (4).

- Manual/Remote Throw: A switch-lever (10) and associated linkage allow the operator to manually throw the switch open to the siding.

2. Locking Mechanism (Locking to Siding)

- Bell-Crank Locking-Lever (39): A lever adapted to engage a tooth (40) on the underside of the switch-rail plate (5).

- Function: When the switch is thrown open to the siding, this arm locks the plate (5) in position to maintain the siding track alignment.

- Latch/Pawl System (24, 28): A spring-loaded latch (25) and pawl (28) are housed beneath the track.

- Function: This secondary lock controls the primary release mechanism and is integrated with the counterweight-shaft (30).

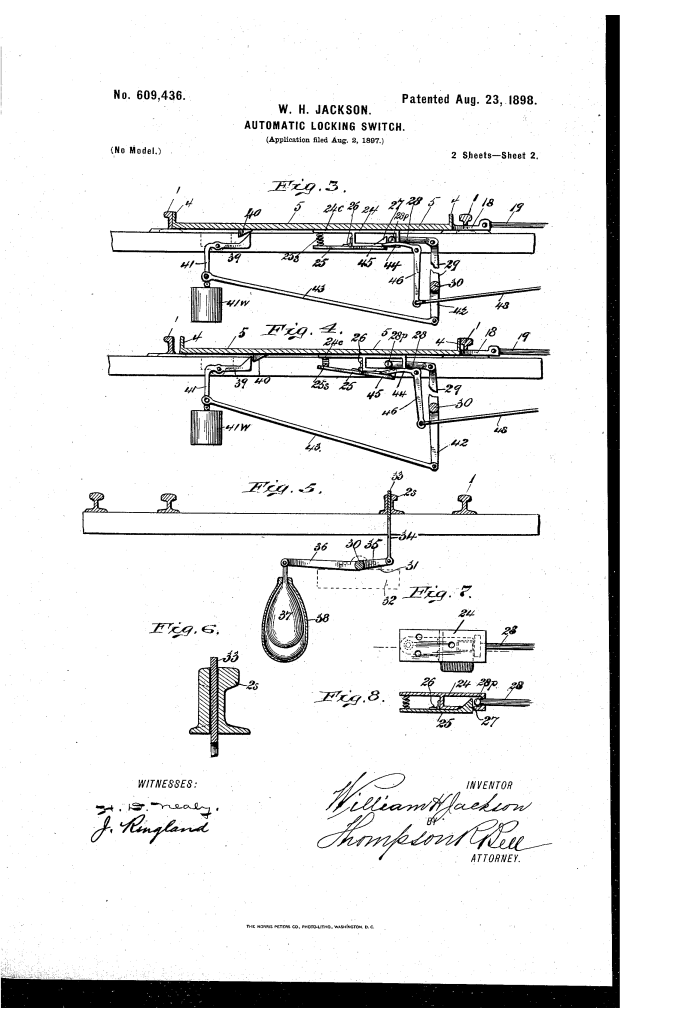

3. Train-Actuated Sequence (Key Innovation)

- Trip-Rail (33): A short rail set into a slot in the web of the siding rail (2) so that it projects above the surface. It is connected via rods (34) to a lever (35) on the counterweight-shaft (30).

- Counterweights (37): Weights suspended from levers (36) on the counterweight-shaft (30).

- Operation Sequence:

- Train Enters Siding: The train wheels press down the trip-rail (33), which is kept depressed as long as any car rests on it.

- Lock-Activation/Weight Lift: The trip-rail’s depression rotates the counterweight-shaft (30), simultaneously lifting the counterweights (37) and positioning the pawl (28) to engage the latch (25).

- Release and Return: When the last wheel moves off the trip-rail (33), the counterweights (37), relieved of the wheel pressure, descend immediately. This descent forcefully rotates the shaft (30), which operates the final switch linkage, automatically throwing the switch plate (5) back to the main line (closed position).

- Fail-Safe Principle: The entire system relies on the weight of the train to store energy (by lifting the counterweight 37) and then uses that stored energy to perform the fail-safe return to the main track.

Concepts Influenced by This Invention

Jackson’s automatic locking switch influenced subsequent railway and heavy industrial control by pioneering load-dependent, sequenced automation for safety.

- Load-Dependent Safety Interlocks: The core concept of using the presence of a load (a train wheel) on a sensor (trip-rail 33) to store energy (counterweight 37) and then using the removal of that load to trigger the final corrective action is a key principle in industrial automation and safety systems.

- Mechanical Sequential Control: The use of the counterweight-shaft (30) to perform a sequence of internal actions (lifting the weight, positioning the pawl, and driving the return) is a robust mechanical solution for timed, sequential control influencing the design of indexing mechanisms and automated machinery that rely on mechanical synchronization.

- Track Circuit Precursor: The trip-rail (33) functions as a mechanical track circuit, signaling the presence of a vehicle over a specific distance. This principle influenced the later development of electrical track circuits that sense train presence using electrical current.

- Integrated Locking and Return: The system’s integration of the locking mechanism (39) and the automatic return mechanism (37) onto a single drive shaft influenced the design of industrial switches and safety gates, ensuring that the act of operation is inherently tied to the condition of safety.