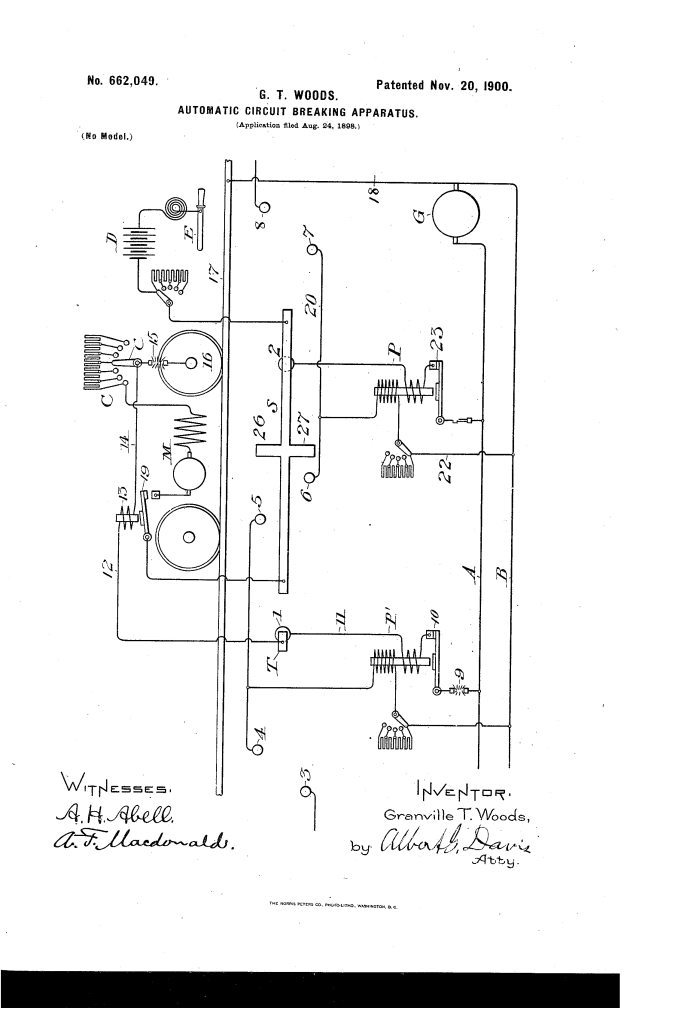

Automatic Circuit-Breaking Apparatus (Granville T. Woods, No. 662,049)

The patent by Granville T. Woods of Monsey, New York, describes an Automatic Circuit-Breaking Apparatus (Patent No. 662,049, 1900) for use with sectional contact electric railways. The key object is to automatically interrupt the action of the driving motor on the car whenever a track-side switch fails to cut power to a section after the car has passed. This compels the operator to stop and attend to the fault.

Inventor Background: Granville T. Woods

Granville T. Woods (1856–1910) was an incredibly prolific and important African-American inventor known as the “Black Edison,” specializing in electrical systems and railway technology. His work on electric railways was characterized by innovative solutions for power transfer and, most importantly, fail-safe mechanisms to ensure electrical safety and system reliability.

Invention and Mechanism (Simplified)

The system uses a dedicated “test” contact on the car to detect power in a section that should be dead. If power is detected, an internal circuit-breaker is triggered, stopping the car.

1. Sectional Power System

- Track Contacts: The track consists of sectional working contacts (1, 2, etc.) and supplemental/pickup contacts (3, 4, etc.).

- Electromagnetic Switches (P): Track-side electromagnetic switches control the flow of current from the main source (Generator G) to the working contacts.

- Normal Operation: As the car moves onto a section, the preceding section’s switch should open, cutting power to that section.

2. Fault Detection (The Test Circuit) (Key Innovation)

- Main Contact Shoe (S): The primary collector shoe that draws power for the motor (M).

- Test Contact Shoe (T): A separate contact shoe positioned on the car immediately behind the main shoe (S).

- Fault Sequence (When Switch Fails):

- The car moves forward. The main shoe (S) draws power from contact 2.

- The test shoe (T) passes over the previous contact (1), which should be dead.

- If the switch (P) for contact 1 failed to open, the test shoe (T) detects live power on contact 1.

3. Automatic Safety Interruption

- Short Circuit Trigger: When the test shoe (T) detects the live contact (1), it completes a short-circuit from Main A $\rightarrow$ through a fuse (9) $\rightarrow$ through the test shoe (T) $\rightarrow$ through an internal magnet (13) $\rightarrow$ to Main B.

- Circuit Breaker: The massive, abnormal current from the short circuit blows fuses (9 and 15) and energizes the internal magnet (13), which physically moves a switch (19).

- Result: This action opens the motor circuit at several points, instantly depriving the motor (M) of power and compelling the car to stop until repairs are made.

4. Restart Procedure

Since the car is now stuck, the operator must manually use a separate, small “pick-up battery” (D) and a hand-operated circuit-closer (E) to send a temporary charge to the track-side switch (P), forcing it to open (correcting the fault) before the main power is restored and the motor can resume operation.

Concepts Influenced by This Invention

Woods’s apparatus influenced subsequent electrical safety and monitoring systems by pioneering the active, on-board detection of infrastructure faults.

- Active Fault Detection (Test Circuit): The most significant influence is the concept of using a dedicated, secondary sensor (Test Shoe T) on the vehicle to actively test the state of the infrastructure (track section) immediately behind the main operation. This influenced the design of:

- Monitoring Systems: Advanced maintenance and control systems in railways and industrial automation that constantly monitor the health of the infrastructure they interact with.

- Energy-Triggered Safety System: The use of a short circuit and fuses to generate the massive, instantaneous energy required to activate the on-board circuit-breaking magnet (13) is a clever piece of electrical safety engineering, ensuring the fault itself provides the power to initiate the shutdown.

- Sectional Rail Safety: This system represents a vital step in perfecting the safety of sectionalized power rail systems. It provided the necessary fail-safe to guarantee a dead section was indeed dead, preventing electrocution hazards for track workers.

- Sequenced Start-Up/Maintenance Override: The requirement for a manual, low-power override (battery D and closer E) to correct the fault before the main power is restored influenced the design philosophy of modern safety systems, ensuring that a fault cannot be ignored and requires conscious, deliberate intervention to restart.