Automatic Cashier (Bertram F. Baker, No. 1,582,659)

The patent by Bertram F. Baker of Tannersville, New York, describes an Automatic Cashier (Patent No. 1,582,659, 1926). This invention is a sophisticated coin-handling machine designed to operate as a self-service terminal for fares, fees, or commodities. Baker’s primary objective was to automate the role of a human cashier or ticket seller by providing a mechanism that could receive various denominations of coins, detect fraud (slugs or light coins), and automatically return the correct change. His innovation centers on an electro-magnetic slide system that synchronizes change delivery with the internal transfer of the paid coin.

Inventor Background: Bertram F. Baker

Bertram F. Baker was an African American inventor and engineer active during the early 20th century, a time of rapid urban expansion and the rise of automated transit (like the New York City Subway). Baker specialized in high-precision mechanical and electrical systems. His 1926 patent addressed the need for “rapid repetition” to accommodate moving crowds, showcasing his mastery of integrated circuit logic and mechanical fail-safes. By designing a machine that could handle 50-cent coins and return precise change for an 8-cent fee, he pushed the boundaries of what automated retail could achieve.

Key Mechanical & Electrical Systems

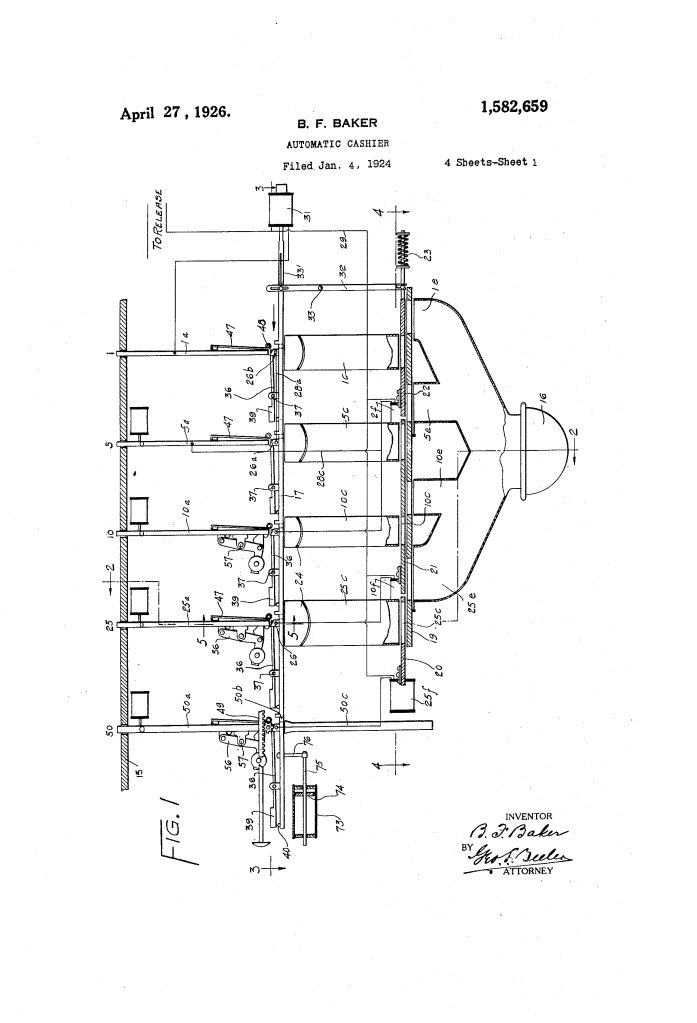

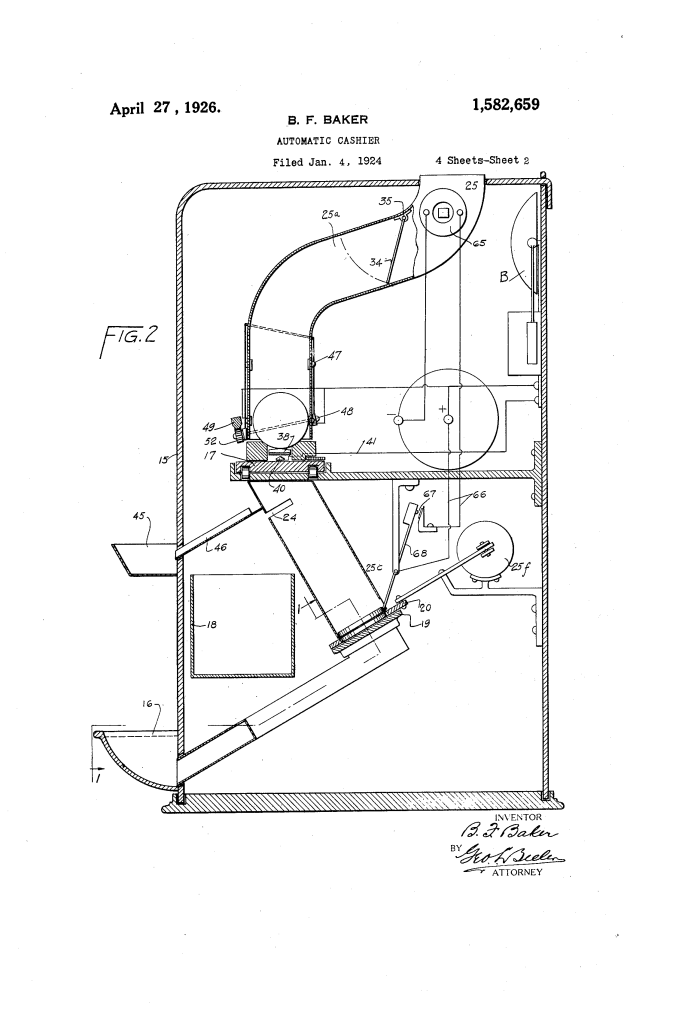

The machine utilizes a combination of gravity-fed chutes, electrical contact points, and solenoid-driven slides.

1. The Coin Selection and Transfer Mechanism (17, 50)

- The Slots and Chutes: Coins are inserted into specific slots (1¢ to 50¢).

- The Transfer Slide (17): A horizontal plate with slits (50) that are normally offset from the chutes.

- Function: When a coin is inserted, it hits the slide and stops, bridging two electrical contacts (26, 27). This completes a circuit that energizes a solenoid to shift the slide, allowing the coin to fall through the slit into its designated magazine or tray.

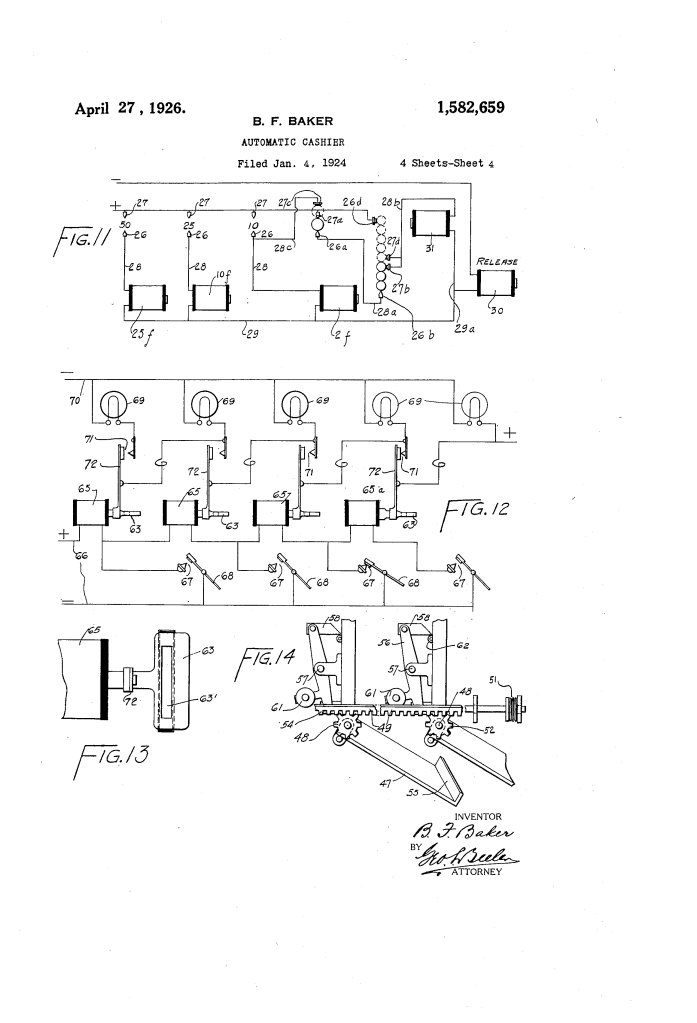

2. Change Delivery Solenoids (20, 21, 22, 25′)

- Solenoid Grouping: Three primary solenoids (25′, 10′, 2′) are linked to slidable change plates.

- Logic-Based Delivery:

- If a 50-cent coin is inserted, solenoid 25′ is triggered, moving all three plates (20, 21, 22) to release a quarter, a dime, a nickel, and pennies.

- If a quarter is inserted, only the plates to the right move to release a dime, nickel, and pennies.

- Function: This “cascading” mechanical logic ensures that only the correct combination of change is dropped into the change cup (16) based on the value of the “master coin.”

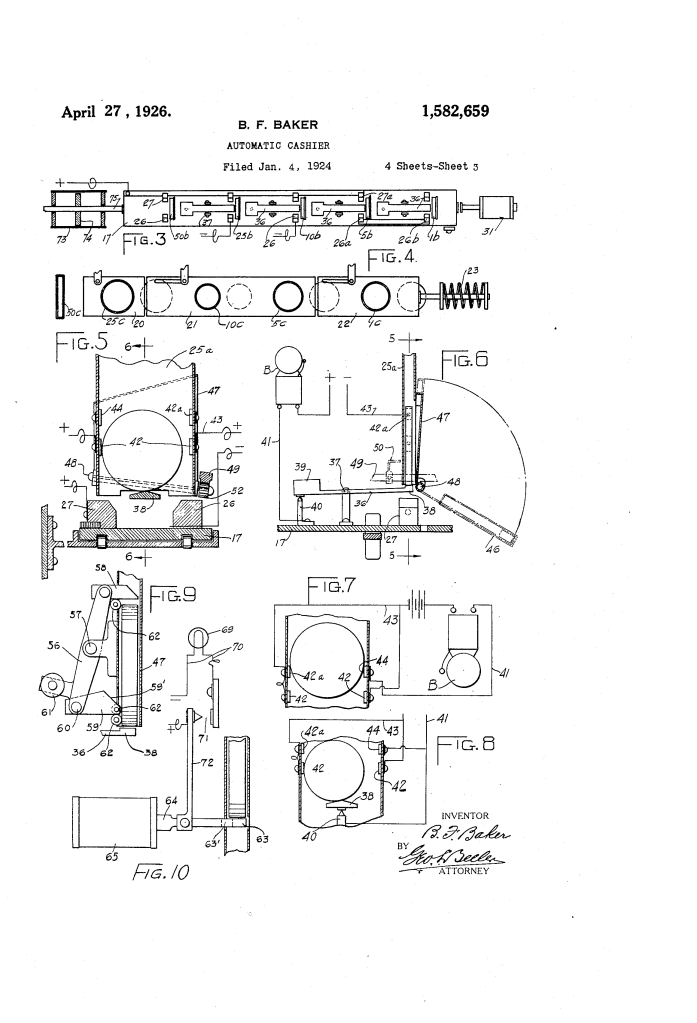

3. Fraud and Weight Detection (36, 38, 39) (Key Innovation)

Baker engineered a sophisticated “scale” within each chute to detect slugs or light coins.

- Scale Beam (36): A pivoted beam with a double-inclined head (38) and a counterweight (39).

- Standard vs. Light Coins: A standard-weight coin strikes the beam and continues down. A light coin (or slug) fails to move the beam and instead bridges a contact to trigger an alarm bell (B).

- Large Coin Check: If a coin is too large in diameter, it gets stuck between two contacts (42, 44), also triggering the alarm.

4. The Tandem Coin Controller (56, 58, 59)

- Succession Management: To allow one person to pay for a group, Baker added a lever (56) and dog (58) system.

- Function: This “segregates” multiple coins inserted into the same slot. It holds back the second coin until the first has been fully processed and transferred, preventing the weighing mechanism from getting jammed or miscalculating.

Improvements Over Standard Cashiers

| Feature | Human Cashiers / Simple Banks | Baker’s Automatic Cashier |

| Speed | Limited by human reaction and counting. | Almost instantaneous electro-magnetic execution. |

| Fraud Detection | Relied on visual inspection. | Scale-beam (36) and contact checks for weight/diameter. |

| Availability | Restricted to business hours. | 24/7 operation for transit and retail. |

| Reliability | Prone to counting errors. | Hard-wired logic slides ensure consistent change return. |

Significance to Engineering and Automation

Bertram F. Baker’s automatic cashier influenced the development of vending technology and automated transit systems.

- Logic-Driven Actuation: Baker’s use of solenoids to trigger “stepped” physical responses based on different electrical inputs is a direct precursor to the logic used in modern vending machines and PLC (Programmable Logic Controller) systems.

- Automated Fraud Prevention: The mechanical weight-detection scales used here evolved into the electronic coin validators and optical sensors used in modern parking meters and laundromat machines.

- System Status Indicators: The inclusion of slot-closers (63) and indicator lamps (69) to signal an “empty magazine” is a standard feature in modern UI/UX design for self-service hardware.

- Damping for Reliability: The use of a dash pot (73) to prevent “too sudden movement” shows a mastery of control systems, ensuring that mechanical parts don’t wear out or jam due to excessive force.