Automatic Air-Brake (Granville T. Woods, No. 627,735)

The patent by Granville T. Woods of New York, N.Y., describes certain new and useful Improvements in an Automatic Air-Brake (Patent No. 627,735, 1899). This invention is a highly complex refinement of the existing air-brake systems, aiming to significantly increase the reliability and quickness of the brake action and provide redundancy to prevent system failure.

Inventor Background: Granville T. Woods

Granville T. Woods (1856–1910), was an exceptionally prolific African-American inventor whose work revolutionized railway technology. This patent is a crucial, late-career contribution, addressing the safety flaws (slow response and failure modes) of the standard Westinghouse air-brake system, which was critical for controlling long, heavy trains.

Invention and Mechanism (Simplified)

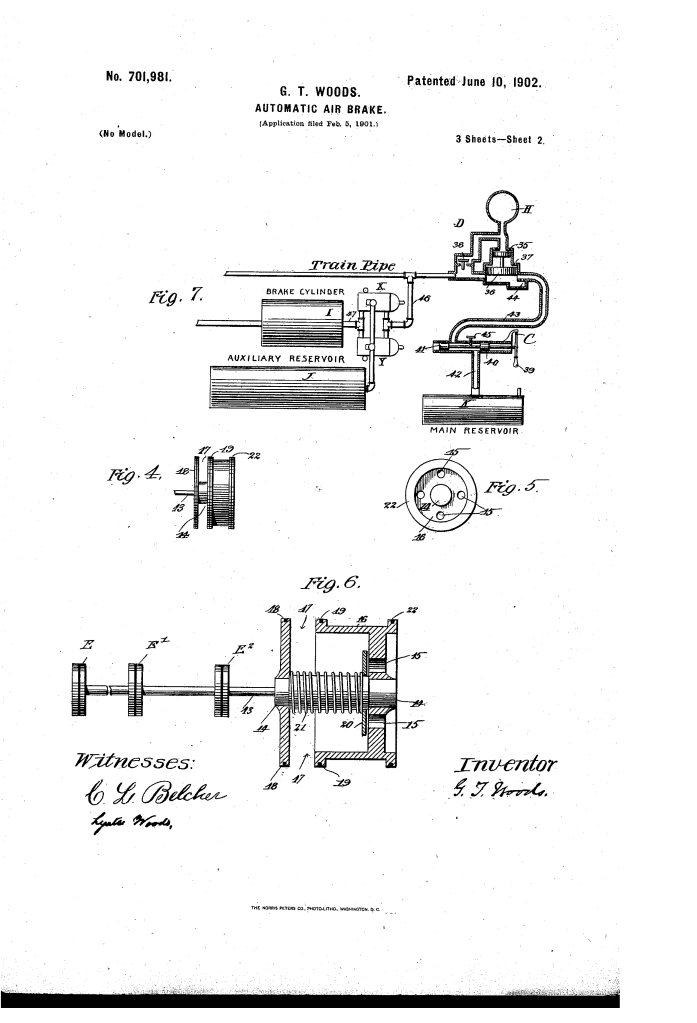

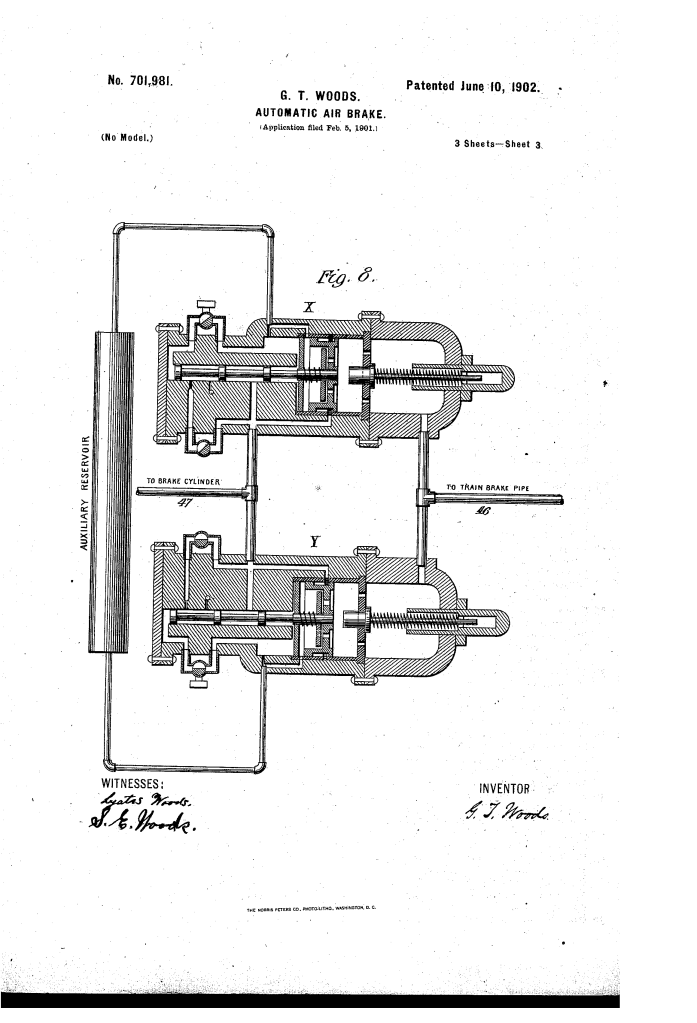

The invention centers on using two separate, parallel valve devices (X and Y) on each car, operating independently but differentially, to ensure the brakes always apply in an emergency.

1. The Air Brake Problem

The standard air-brake (like the Westinghouse Triple Valve) relies on a reduction of air pressure in the main train-pipe to apply the brakes. If one valve fails to operate, the air pressure doesn’t drop quickly enough, causing the other brakes to “lag” (apply slowly), which is extremely dangerous.

2. Dual, Independent Valve Devices (X and Y) (Key Innovation)

- Redundancy: The car is equipped with two complete valve devices (X and Y), each permanently and independently connected to the train-pipe, the auxiliary reservoir, and the brake-cylinder.

- Independent Action: The core principle is that the action of one valve device is absolutely independent of the condition or action of the other. If one fails, the other will still apply the brakes.

3. Differential Emergency Action

- Graduating Valve (Y): One device (Y) is set to act as the graduating main valve, controlling gradual stops.

- Differential Piston/Emergency Valve (X): The second device (X) is configured as a differential piston that remains normally inert.

- Function: When the engineer initiates an emergency stop (sudden, large pressure drop in the train-pipe), the differential pressure instantly moves the inert piston (X) to its full limit. This opens a second, large pathway for air to rush from the auxiliary reservoir and the train-pipe directly into the brake-cylinder.

- Result (Speed and Reliability): The redundant, independent emergency valve (X) ensures that even if the primary valve (Y) fails or is slow, the emergency air supply is guaranteed to reach the brake-cylinder instantly, greatly increasing the reliability of the system.

4. Auxiliary Advantages

- Fast Recharging: The valve design includes large, direct passages to the auxiliary reservoir, allowing the engineer to recharge the auxiliary reservoir instantaneously while the brakes are still applied (a necessity when running downgrade).

- Restricted Exhaust: The exhaust passage from the brake-cylinder is restricted, causing the brakes to release gradually, which is standard for smooth train operation.

Concepts Influenced by This Invention

Woods’s air brake influenced subsequent safety-critical systems by establishing the concept of active, redundant, differential control for critical industrial functions.

- Redundant Control Systems (Absolute Independence): The most significant influence is the engineering requirement of using two parallel, independent control units for a single critical function (applying brakes), ensuring that the failure of one unit does not impair the operation of the second. This is foundational to safety systems in aerospace, nuclear, and critical industrial control.

- Differential Actuation and Quiescence: The concept of using a differential piston (X) that is normally inert (balanced) but moves instantly when a specific, large pressure change (emergency) occurs influenced the design of industrial safety valves and switches that only activate under catastrophic fault conditions.

- System Reliability and Safety: This patent contributed significantly to the shift in railway safety philosophy, emphasizing that air brake systems must not only work well but must also be designed to act positively and powerfully even when components fail.

- Fluid Control for Speed: The complex valve work necessary to regulate air pressure for both slow, proportional stops (graduating) and instantaneous, full-force stops (emergency) influenced the design of sophisticated pneumatic and hydraulic control manifolds.