Apparatus for Washing Vehicles (William Henry Phelps, No. 579,242)

The patent by William Henry Phelps of Indianapolis, Indiana, describes an Apparatus for Washing Vehicles (Patent No. 579,242, 1897). The invention consists of a system for suspending a washing hose and guiding it around a vehicle. The core innovation is a novel swivel pipe-joint designed to allow the hose to swing freely overhead, following the operator, without leakage.

Inventor Background: William Henry Phelps

William Henry Phelps was an inventor contributing to the utility and efficiency of late 19th-century infrastructure, specifically focusing on solutions for domestic or commercial vehicle maintenance (stables and carriage-houses). His device aimed to solve the practical problems of tangling, dragging, and leakage associated with long water hoses used in washing bays.

Invention and Mechanism

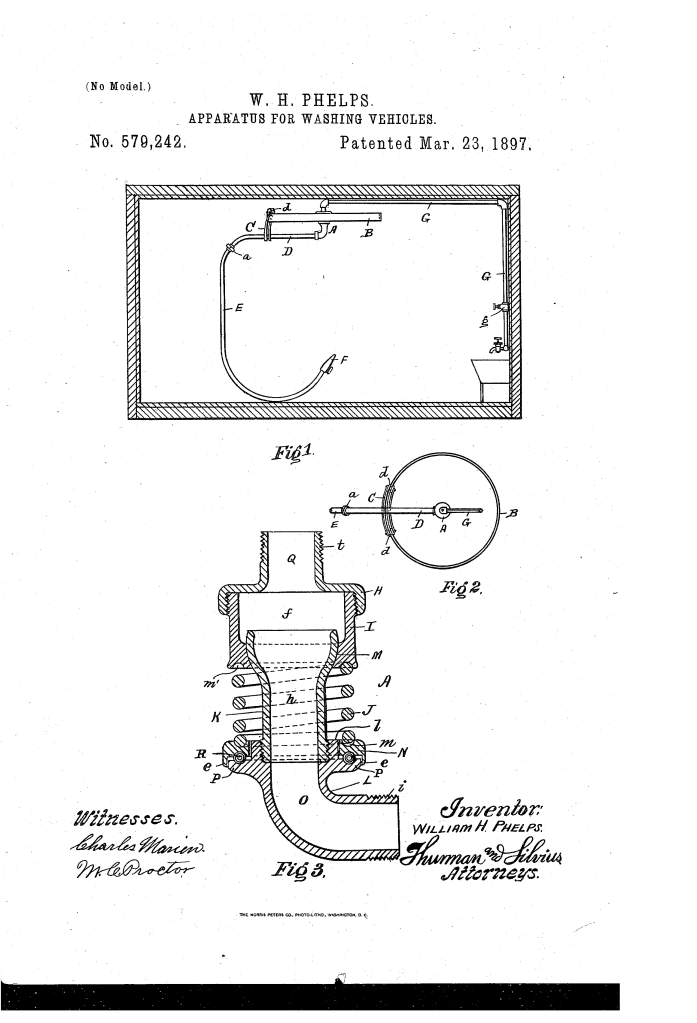

The apparatus is an overhead hose suspension system that uses a circular track and a complex, leak-proof swivel joint.

1. Suspension and Guidance

- Circular Track (B): A track (supported by brackets) secured to the ceiling of the washing room.

- Swinging Pipe (D): A pipe arm that swings freely beneath the track.

- Carriage (C): A carriage with rollers (

) that supports the outer end of the swinging pipe (D) and travels around the circular track (B).

- Hose (E) and Nozzle (F): The hose and nozzle are attached to the bent, downward-projecting outer end of the pipe (D).

- Function: As the operator moves the nozzle (F) around the vehicle, the hose (E) draws the pipe arm (D), which rotates the swivel joint, and the carriage (C) travels around the track (B). This keeps the hose overhead and out of the way of the vehicle and the operator.

2. The Leak-Proof Swivel Joint (Key Innovation)

The swivel joint (A) connects the fixed water-supply pipe (G) to the rotating pipe (D).

- Ball-and-Socket Joint (M): The core of the seal is a spherical joint formed by the fitting of the cup-shaped part (I) over the swivel-piece (K). This allows for both rotation and flexibility without leakage.

- Ball Bearings (R): Ball bearings are placed in grooves between a flange (P) on the elbow (L) and a collar (N).

- Function: The ball bearings permit easy, low-friction rotation of the pipe arm (D) as the operator moves.

- Spring (J): A spring is seated between an annular groove on the cup (I) and an annular groove on the collar (N).

- Function: The spring maintains constant pressure on the internal components and seals, ensuring the joint remains watertight during rotation and movement.

Concepts Influenced by This Invention

Phelps’s swivel joint influenced subsequent fluid and mechanical systems by pioneering a durable, low-friction, overhead fluid supply system.

- Overhead Utility Swivels: The core concept of a ceiling-mounted, circular track guiding a boom arm attached via a leak-proof, low-friction swivel is the standard design for modern overhead retractable air hoses, high-pressure washers, and utility lines in garages, workshops, and industrial bays.

- Rotational Fluid Sealing: The combination of a spherical ball-and-socket joint (M), ball bearings (R) for smooth rotation, and a compression spring (J) to maintain a constant seal influenced the design of sophisticated rotary unions and fluid swivels used in manufacturing and robotics that must transfer hydraulic fluid or water while rotating 360 degrees.

- Ergonomics in Tool Management: The apparatus is a precursor to modern ergonomic solutions aimed at keeping tools and supply lines off the floor, reducing tripping hazards, tangling, and wear on the hose itself.