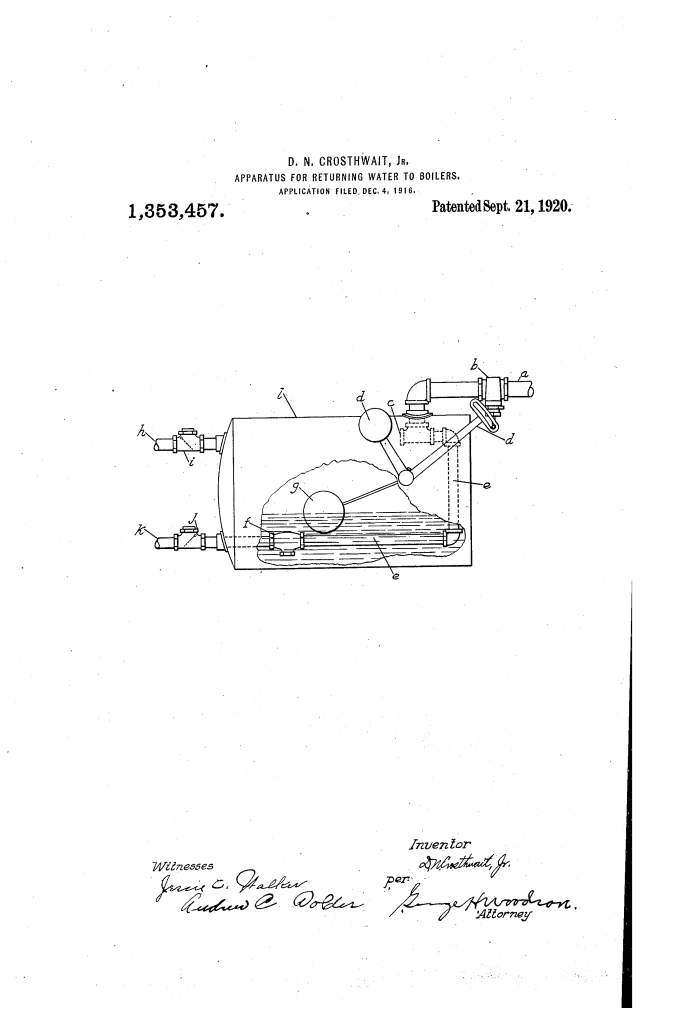

Apparatus for Returning Water to Boilers (David N. Crosthwait, Jr., No. 1,353,457)

The patent by David N. Crosthwait, Jr. of Marshalltown, Iowa, describes an Apparatus for Returning Water to Boilers (Patent No. 1,353,457, 1920). This invention is a specialized steam-operated pump or “return trap” designed to return water of condensation to a boiler from a level lower than the boiler’s water line. Crosthwait’s design is a major improvement in heating engineering, as it utilizes both direct steam pressure and an internal ejector to overcome the resistance of boiler pressure without the need for large, external mechanical pumps.

Inventor Background: David N. Crosthwait, Jr.

David Nelson Crosthwait, Jr. (1898–1976) was a world-renowned African American engineer, inventor, and expert in steam pressure, ventilation, and heat transfer. Over his prolific career, he received 39 U.S. patents and 80 foreign patents related to HVAC systems. He is most famous for designing the heating system for Radio City Music Hall in New York City. This 1920 patent, filed when he was in his early twenties, demonstrates his early mastery of thermodynamics and fluid mechanics, providing a solution for industrial and residential steam systems that was both compact and highly effective.

Key Mechanical Components & Functions

The apparatus consists of a pressurized receiver tank containing an automatic float-operated valve system and an internal steam ejector.

1. The Receiver and Inlet/Outlet (Z, h, k)

- The Receiver (Z): A heavy-duty tank (trap) that collects water of condensation via a water inlet pipe (h) equipped with a check valve (i).

- The Discharge (k): Once full, the water is expelled through a discharge pipe (k) and past a check valve (j) to be returned to the boiler.

2. The Float-Operated Trip Mechanism (g, d, b)

- The Float (g): Inside the receiver, a float (g) rises as the water level increases.

- The Rock Shaft and Weighted Arm (d): The float is attached to a shaft that extends outside the tank to a weighted arm (d).

- Steam Valve (b): When the water reaches a specific height, the weighted arm “trips” the valve (b).

- Function: This valve cuts off the tank from the atmosphere and opens the path for high-pressure steam from the boiler to enter the system.

3. The Dual Steam Injection System (o, f) (Key Innovation)

When the steam valve opens, the steam is diverted in two directions to perform two simultaneous tasks:

- The Surface Nozzle (o): Part of the steam enters through a nozzle (o) at the top of the receiver.

- Function: It exerts direct pressure on the surface of the water, physically “pushing” it downward into the discharge area.

- The Submerged Ejector (f): The remaining steam flows through a pipe (e) at the bottom of the receiver into an ejector (f).

- Function: The high-velocity steam flowing through the ejector nozzle creates a powerful suction (using the Venturi effect) that draws the water from the receiver and forces it through the discharge pipe (k) with enough pressure to overcome the boiler’s internal resistance.

4. Automatic Reset

- Emptying: As the water level drops, the float (g) falls.

- Tripping Off: When the float reaches the bottom, the trip mechanism closes the steam valve (b), cutting off the steam supply and reopening the receiver to the atmosphere. This allows the cycle to repeat as the tank begins to refill with condensation.

Improvements Over Standard Return Traps

| Feature | Standard Steam Traps | Crosthwait’s Apparatus |

| Pumping Power | Relied purely on gravity or simple pressure. | Uses dual action: surface pressure + ejector suction. |

| Efficiency | Often suffered from “stalling” when pressures equalized. | Ejector creates a “pressure preference” to ensure water flow. |

| Design | Bulky external pumps and piping. | Compact internal arrangement of nozzle and ejector. |

| Material Use | Required heavy castings for external pumps. | Reduced space and material through integrated internal components. |

Significance to Heating and Fluid Engineering

David N. Crosthwait, Jr.’s apparatus influenced the development of modern steam heating and fluid propulsion.

- The Venturi Principle in HVAC: His use of an internal ejector to assist in water return is a classic application of the Venturi effect, which remains a fundamental principle in modern boiler feed systems and chemical injectors.

- Atmospheric Balancing: The automatic transition between atmospheric pressure (for filling) and boiler pressure (for discharging) is a core logic found in modern condensate return pumps.

- Space Optimization: By housing the entire pumping mechanism inside the receiver, Crosthwait pioneered the “all-in-one” design philosophy that is standard in modern industrial equipment.

- Thermodynamic Management: His explanation of how steam initially condenses to “build up pressure” demonstrates a deep understanding of latent heat and phase changes, essential for the high-efficiency systems he later designed for massive landmarks.